BIODIESEL synthesis

A technology of biomass diesel and natural oil, applied in the field of equipment ships, can solve problems such as affecting the equilibrium position rate, affecting the total conversion degree of oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

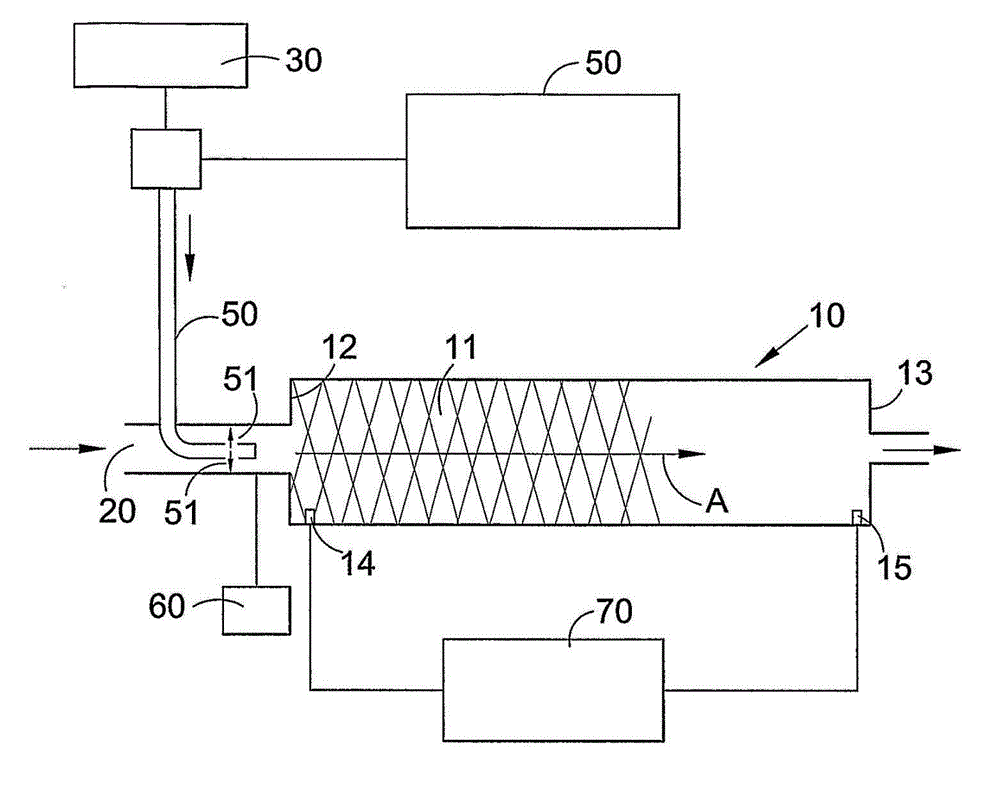

[0186] A stream of sunflower oil heated to 80° C. was fed at a flow rate of 30 L / h at a pressure of 4 bar gauge into a tubular reactor with a diameter of 6 mm.

[0187] The tubular reactor was insulated but not individually heated and had a length of 15 m. Kenics TM A KMX mixer element was placed in the reactor and filled 60% of the tube length.

[0188] A supply of KOH and methanol at room temperature was prepared and fed under pressure into the sunflower oil stream through nozzles extending at right angles to the direction of flow of the sunflower oil to create turbulent flow.

[0189] The mass ratio of sunflower oil to methanol flow rate was 4:1.

[0190] KOH and methanol were mixed initially at a weight ratio of 24.5 g solid KOH to 1 L dry methanol.

[0191] The residence time of the reaction mixture was 90 s.

[0192] Plug flow as measured by the method described above was maintained in excess of 90%.

[0193] The time it takes for 90% of the fluid components to pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com