A kind of method for preparing ts-1 molecular sieve

A TS-1, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of high production cost, environmental pollution and high price of molecular sieve, and achieve the effect of shortening crystallization time, reducing production cost and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add tetrapropylammonium hydroxide and deionized water to butyl titanate, stir evenly to form A solution; stir ethyl orthosilicate and deionized water evenly to prepare B solution. Add solution B slowly to solution A under stirring, stir vigorously for 3 hours to make a mixed gel, the molar composition of the mixed gel is TiO 2 : SiO 2 =1:30~150,TPAOH:SiO 2 =0.25~0.40,H 2 O: SiO 2 =8~12. Transfer the mixed gel into a closed stainless steel reaction kettle with a polytetrafluoroethylene liner, crystallize at a temperature of 130-160°C for 3-24 hours, then cool to room temperature, and make a seed crystal to be prepared use.

[0028] Add isopropanol solution to butyl titanate to make solution A; weigh silica sol, NaOH and deionized water, stir well to make solution B; add solution A to solution B to make a molar ratio of TiO 2 : SiO 2 =1:30~150, Na 2 O: SiO 2 =2.0~3.5, H 2 O: SiO 2 =20~35, TiO 2 : IPA = 1:2 mixed gel, then add a certain amount of seed crystals ...

Embodiment 2

[0030] Add 0.195g of butyl titanate to 5.0g of tetrapropylammonium hydroxide and 0.267g of deionized water, stir evenly, and prepare A solution; weigh 3.691g of tetraethyl orthosilicate and slowly add to In solution A, stir vigorously for 3 hours to form a mixed gel, and the molar composition of the mixed gel is TiO 2 : SiO 2 =1:30,TPAOH:SiO 2 =0.357,H 2 O: SiO 2 =10.8. The above mixed gel was sealed in a stainless steel reactor with a polytetrafluoroethylene liner, crystallized at 140° C. for 9 hours, then taken out and cooled to room temperature to obtain seed crystals.

Embodiment 3

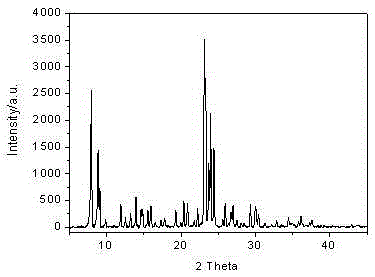

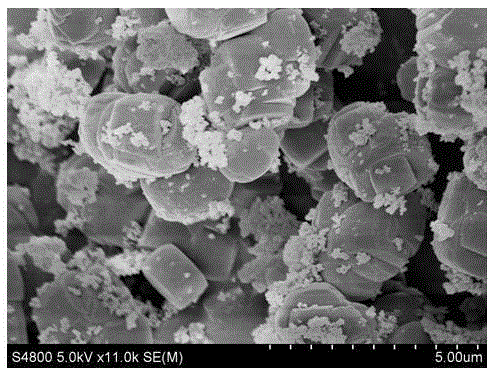

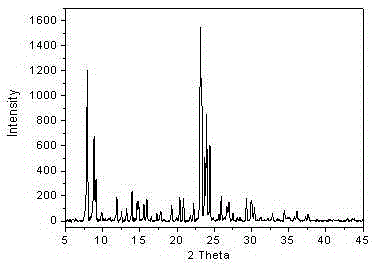

[0032] To 11.5g of silica sol (SiO 2 content is 40%), add 10g of water, weigh 0.75g of NaOH and 16.75g of deionized water, add it to the silica sol, stir evenly, and make A solution; weigh 0.85g of butyl titanate and add it to 2.32g of isopropanol, And drop into the A solution to make the molar ratio TiO 2 : SiO 2 =1:30, Na 2 O: SiO 2 =2.5,H 2 O: SiO 2 =25,TiO 2 : The mixed gel of IPA=1:2, add the seed crystal that accounts for mixed gel total amount 5% that is made by the method for embodiment 2 again, transfer to the stainless steel tank with polytetrafluoroethylene liner after stirring evenly In a closed reaction kettle, crystallize at 170°C for 24 hours, cool to room temperature, centrifuge the product, wash, dry, and roast to obtain TS-1 molecular sieve with a silicon-titanium ratio of 30 (molar ratio), denoted as TS-1 (30), its XRD spectrum and SEM photos are shown in figure 1 with figure 2 . figure 1 It shows that the synthesized TS-1(30) is a pure phase TS-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com