High-purity zirconium oxide refractory product with gradient function and preparation method thereof

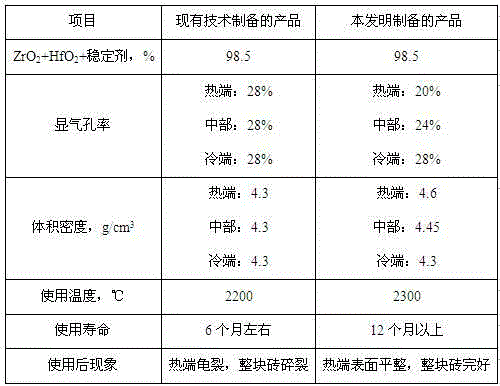

A technology of refractory products and gradient functions, applied in the field of refractory materials, can solve problems such as expansion/contraction deformation mismatch, uneven temperature field distribution, and reduced service life of zirconia products, and achieve low input costs, high use temperature, and improved use. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh fused calcium oxide partially stabilized zirconia particles (stabilization rate 75%), particle size greater than 0.5 mm and less than or equal to 1 mm1 kg, particle size greater than 0.35 mm and less than or equal to 0.5 mm 2.5 kg, particle size greater than 0.15 mm and less than or equal to 0.35 mm 3 kg , premixed in a high-speed kneader for 3 minutes, added 0.3 kg of phenolic resin alcohol solution, continued high-speed stirring for 5 minutes, and then added fused calcium oxide to it and partially stabilized zirconia fine powder (stabilization rate 75%) with a particle size greater than 30 μm is less than or equal to 150 μm 1.5 kg, fused calcium oxide partially stabilized zirconia powder D50 is 10 μm 1 kg, monoclinic zirconia powder D50 is 10 μm 1 kg, stirred at high speed for 10 minutes, sieved, dried, and then loaded into a steel In a mold composed of a core and a rubber sleeve, the green body is formed by isostatic pressing under a pressure of 150 MPa. The gre...

Embodiment 2

[0024] Weigh fused magnesia partially stabilized zirconia particles (stabilization rate: 80%), particle size greater than 0.5 mm and less than or equal to 1 mm 1 kg, particle size greater than 0.35 mm and less than or equal to 0.5 mm 2.5 kg, particle size greater than 0.15 mm and less than or equal to 0.35 mm 3 kg, Pre-mix in a high-speed kneader for 3 minutes, add 0.35 kg of phenolic resin alcohol solution, continue to stir at a high speed for 5 minutes, and then add fused magnesia partially stabilized zirconia fine powder (stabilization rate 80%) to it, with a particle size greater than 30 μm and less than Equal to 150 μm 2 kg, fused magnesia partially stabilized zirconia powder (stabilization rate 80%) particle size D50 is greater than 0.5 μm and less than or equal to 30 μm 1 kg, monoclinic zirconia powder D50 is 2 μm 0.5 kg, after stirring at high speed for 10 minutes, After sieving and drying, put it into a mold consisting of a steel core and a rubber sleeve, and press it ...

Embodiment 3

[0026] Weigh fused yttrium partially stabilized zirconia particles (stabilization rate: 85%), particle size greater than 0.5 mm and less than or equal to 1 mm 1 kg, particle size greater than 0.35 mm and less than or equal to 0.5 mm 2.5 kg, particle size greater than 0.15 mm and less than or equal to 0.35 mm 3 kg, Pre-mix in a high-speed kneader for 3 minutes, add 0.5 kg of phenolic resin alcohol solution, continue to stir at a high speed for 5 minutes, and then add fused yttrium partially stabilized zirconia fine powder (stabilization rate 85%) to it, with a particle size greater than 30 μm and less than Equal to 150 μm 1.5 kg, electric fused yttrium partially stabilized zirconia powder (stabilization rate 85%) D50 is 30 μm 1 kg, monoclinic zirconia powder D50 is 3 μm 1 kg, after stirring for 10 min, sieved and dried Put it into the mold, and press it under 150 MPa to form a green body. The green body has an inner diameter of 500mm, an outer diameter of 600mm, a height of 125m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com