Phenylethyl acetate synthesis method

A technology of phenylethyl acetate and a synthetic method, which is applied to the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of carbon-based compounds, can solve environmental problems, low yields, waste of resources, etc., and achieve low cost, Reduce energy consumption and production costs, easy to separate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

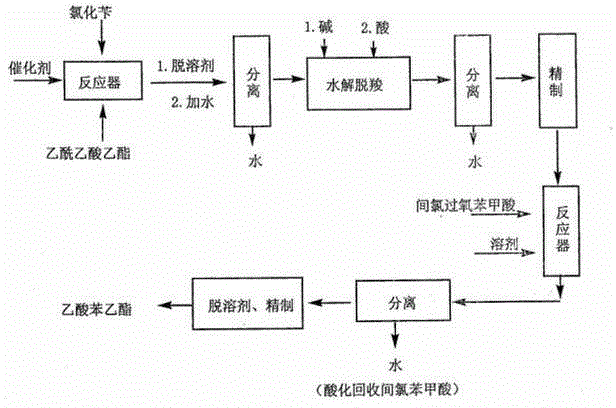

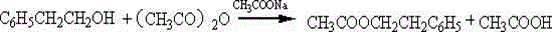

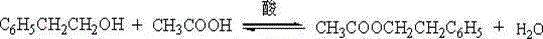

Method used

Image

Examples

Embodiment 1

[0024] In a reaction flask equipped with a stirrer, a reflux condenser, a dropping funnel, and a thermometer, add 42 g of a sodium methoxide solution catalyst with a concentration mass / mass of 30%, and 31 g of ethyl acetoacetate, and stir for 15 minutes. Heat to reflux, add 25.3g of benzyl chloride dropwise, add about 1h, and reflux for 2h to generate ethyl benzyl acetoacetate. Cool to room temperature, add 100ml of water to dissolve and stir well, adjust the pH to 7 with concentrated hydrochloric acid, let it stand for stratification, separate the oily substance in the lower layer, wash with water, and let it stand for stratification again to obtain the product ethyl benzyl acetoacetate.

[0025] Add 60 grams of 5% sodium hydroxide solution to the above product to make the solution alkaline, reflux for 2 hours under stirring, oily matter is formed, cool to below 40°C and add concentrated hydrochloric acid to adjust the pH to 1-2. Continue heating to reflux for 1.5h. The dist...

Embodiment 2

[0028] In a reaction flask equipped with a stirrer, a reflux condenser, a dropping funnel, and a thermometer, add 45 g of a sodium methoxide solution catalyst with a concentration mass / mass of 28%, and 31 g of ethyl acetoacetate, and stir for 15 minutes. Heat to reflux, add 25.3g of benzyl chloride dropwise, add about 1h, and reflux for 3h to generate ethyl benzyl acetoacetate. Cool to room temperature, add 100ml of water to dissolve and stir well, adjust the pH to 7 with concentrated hydrochloric acid, let it stand for stratification, separate the oily substance in the lower layer, wash with water, and let it stand for stratification again to obtain the product ethyl benzyl acetoacetate.

[0029] Add 60 grams of 5% sodium hydroxide solution to the above product to make the solution alkaline, reflux for 3 hours under stirring, oily matter is formed, cool to below 40°C and add concentrated hydrochloric acid to adjust the pH to 1-2. Continue heating to reflux for 2h. The distil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com