Method for preparing flame-retardant thermoplastic polyimide resin

A polyimide and polyesterimide technology, applied in the field of preparation of high-performance flame-retardant thermoplastic polyimide resin, can solve the problems of poor compatibility, deteriorated mechanical properties and electrical properties of materials, etc. The effect of good capacitance, high industrial application value and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A preparation method of flame-retardant thermoplastic polyimide resin, comprising the following steps:

[0043] A. Preparation of Phosphorus-Silicon Synergistic Flame Retardant Thermotropic Liquid Crystalline Polyesterimide

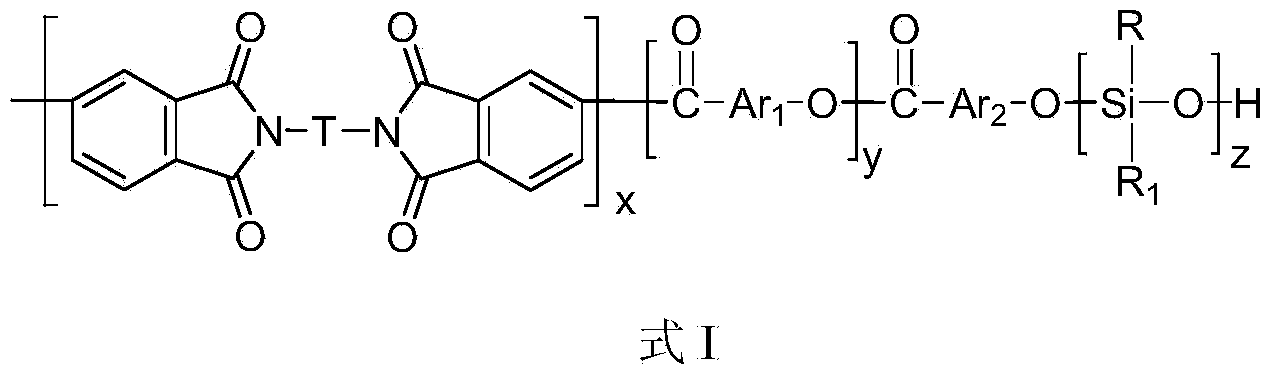

[0044](1) With p-hydroxymethylbenzoic acid as mesogen, PEtI-TLCP is formed by copolymerization of dichlorobisphthalimide, hydroxy acid, phosphorus-containing and silicon-containing monomers; its basic segment structure is as follows :

[0045]

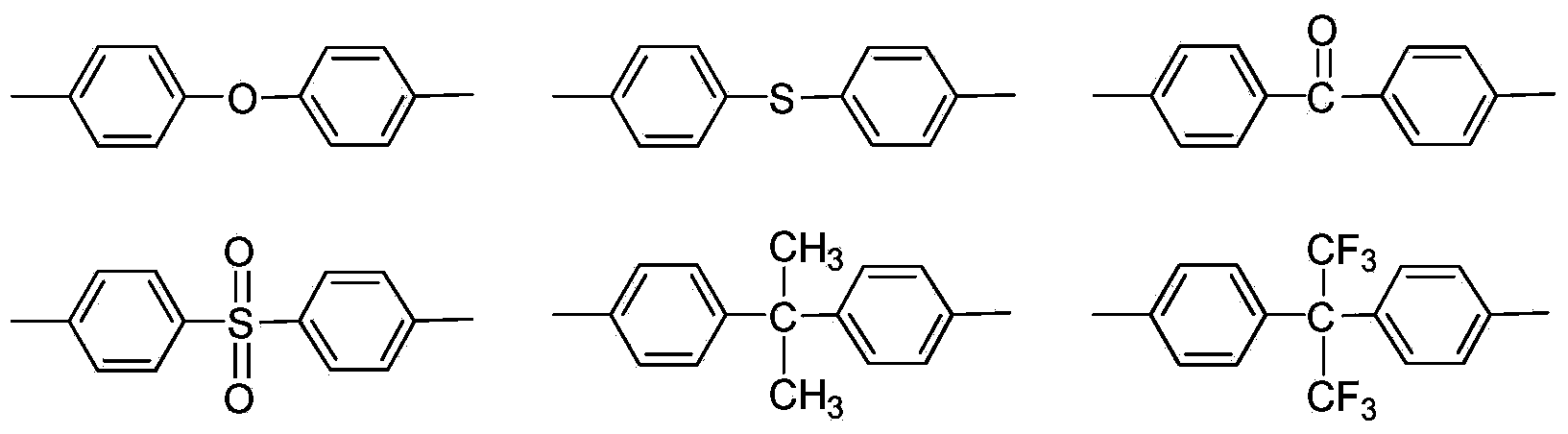

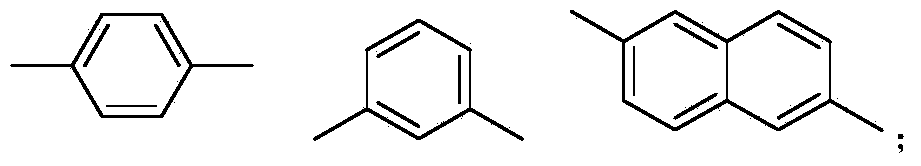

[0046] where R is C 1 -C 3 chain alkyl, R 1 are the same or different methyl, ethyl, and phenyl groups, x is 8-12, y is 5-10, and z is 1-3. T selected from:

[0047]

[0048] (2) The molar percentage of hydroxy acid in the present invention is 30-40%, the molar percentage of said hydroxy acid is 30-35%, the molar percentage of dichlorobisphthalimide is 35-40%, and the phosphorus-containing mono The molar ratio of bulk DOPO and its derivatives to dihydroxysiloxane is 1:3-3:1. Add the above-menti...

Embodiment 1

[0067] (1) Preparation of phosphorus-silicon synergistic flame-retardant thermotropic liquid crystal polyesterimide

[0068] Stirring at a speed of 60-120 rpm, mix 3000mol p-hydroxybenzoic acid (p-HBA), 3500mol dichlorobisphthalimide, 1000mol DOPO, chlorosiloxane containing 2500mol hydroxyl equivalent, 0.4 Add kg esterification catalyst antimony acetate and 0.5 kg polycondensation catalyst antimony trioxide to the reactor with fractionation condenser strong stirrer nitrogen conduit at one time, stir and mix for 10-20 minutes, heat to 180°C for reaction, under nitrogen protection, The by-products formed are carried out with nitrogen. As the viscosity of the reaction system gradually increased, a "rod climbing" phenomenon (indicating the formation of a liquid crystal phase) appeared. The reaction temperature was gradually increased to 290°C, the vacuum was pumped to above 100Pa, and the reaction was carried out for 30 minutes. A light brown solid product was obtained through tr...

Embodiment 2

[0076] The processing parameter of embodiment 2 is exactly the same as embodiment 1, and difference is that the phosphorus silicon flame-retardant type polyester imide liquid crystal (PEtI-TLCP-I) addition amount prepared by embodiment 1 is 40% (by mass percentage) ) mixed with thermoplastic polyimide 60%, the performance test results of the prepared materials are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com