Ultraviolet-curable anti-fingerprint antistatic paint composition

A composition and anti-fingerprint technology, applied in conductive coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems that anti-static coatings do not have anti-fingerprint properties, anti-fingerprint coatings do not have anti-static properties, etc., and achieve anti-static properties Durable, good wear resistance, high light transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

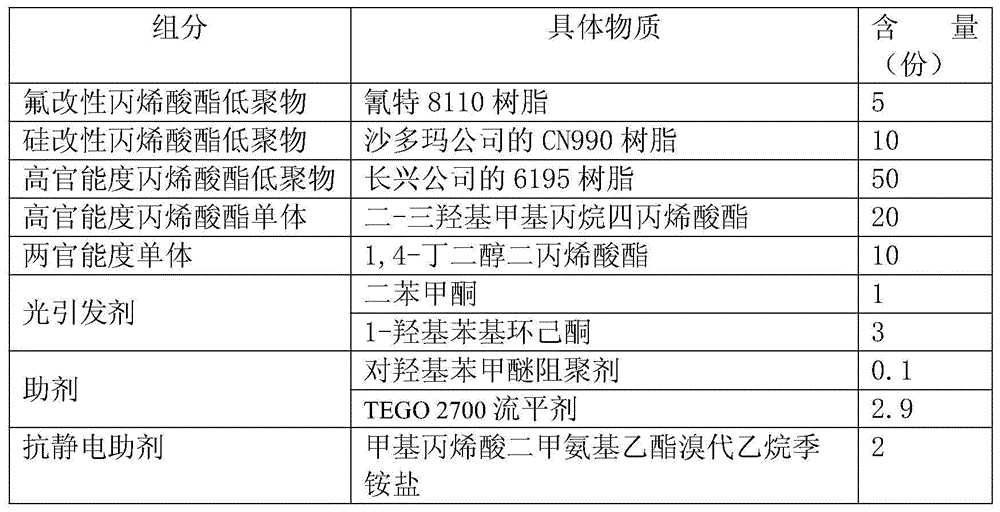

[0035] This embodiment relates to a UV-curable anti-fingerprint and antistatic coating composition, including the components in parts by weight shown in Table 1; each component is taken in parts by weight, and then the components are uniformly mixed, that is Coating compositions can be prepared.

[0036] Table 1

[0037]

[0038] Implementation Effect:

[0039] Mix the paint prepared above with an organic solvent at a mass ratio of 1:1.5, spray it on an acrylic plate, bake it at 45 degrees Celsius for 3 to 5 minutes, and then cure it with ultraviolet light. The curing energy is 900mJ / cm 2, the test results of the UV-curable coating of this formula are as follows:

[0040] 1. The coating is not easy to leave fingerprints, and the surface contact angle (water and oil-tested with diiodomethane) reaches 107 and 68 degrees respectively;

[0041] 2. The anti-fingerprint effect is long-lasting. Press the fingerprint on the coating, wipe it off with a dust-free cloth, and test i...

Embodiment 2

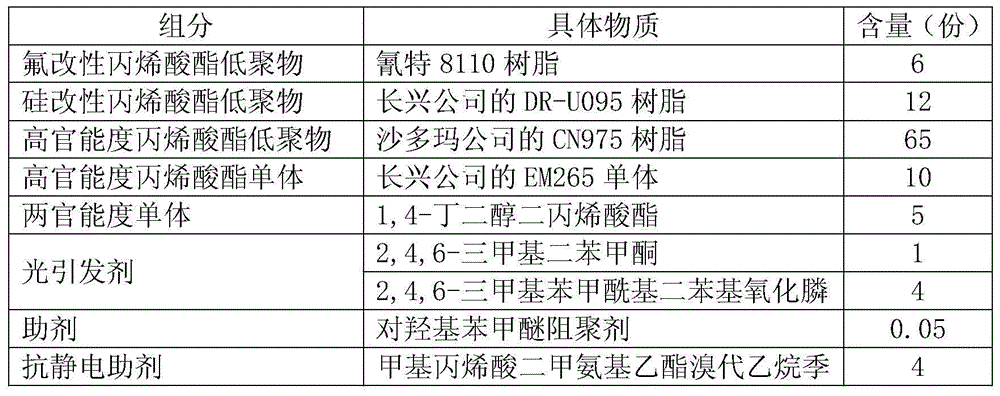

[0049] This embodiment relates to a UV-curable anti-fingerprint and antistatic coating composition, including the components in parts by weight shown in Table 2; each component is taken in parts by weight, and then the components are uniformly mixed, that is Coating compositions can be prepared.

[0050] Table 2

[0051]

[0052]

[0053] Implementation Effect:

[0054] Mix the paint prepared above with an organic solvent according to the mass ratio of 1:1.6, and then spray it on the PMMA surface of the PMMA / PC composite board, bake it at 45 degrees Celsius for 3 to 5 minutes, and then perform UV curing, and the curing energy 850~1000mJ / cm 2 , the test results of the UV-curable coating of this formula are as follows:

[0055] 1. The coating is not easy to leave fingerprints, and the surface contact angle (water and oil) reaches 106 and 67 degrees respectively;

[0056] 2. The anti-fingerprint effect is long-lasting. Press the fingerprint on the coating, wipe it off w...

Embodiment 3

[0063] This embodiment relates to a UV-curable anti-fingerprint and antistatic coating composition, including the components in parts by weight shown in Table 3; each component is taken in parts by weight, and then the components are uniformly mixed, that is Coating compositions can be prepared.

[0064] table 3

[0065]

[0066] Implementation Effect:

[0067] Mix the paint prepared above with an organic solvent at a mass ratio of 1:1.4, and then coat it on an acrylic plate, bake it at 45 degrees Celsius for 3 to 5 minutes, and then perform UV curing with a curing energy of 1000mJ / cm 2 , the test results of the UV-curable coating of this formula are as follows:

[0068] 1. The coating is not easy to leave fingerprints, and the surface contact angle (water and oil) reaches 110 and 69 degrees respectively;

[0069] 2. The anti-fingerprint effect is long-lasting. Press the fingerprint on the coating, wipe it off with a dust-free cloth, and test it repeatedly. The number of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com