Fully automatic control method and system for blast furnace injection system

A blast furnace, injection volume technology, applied in blast furnace, blast furnace details, blast furnace parts, etc., can solve problems such as large injection volume error, achieve stable operation, eliminate system fluctuations, and liberate labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

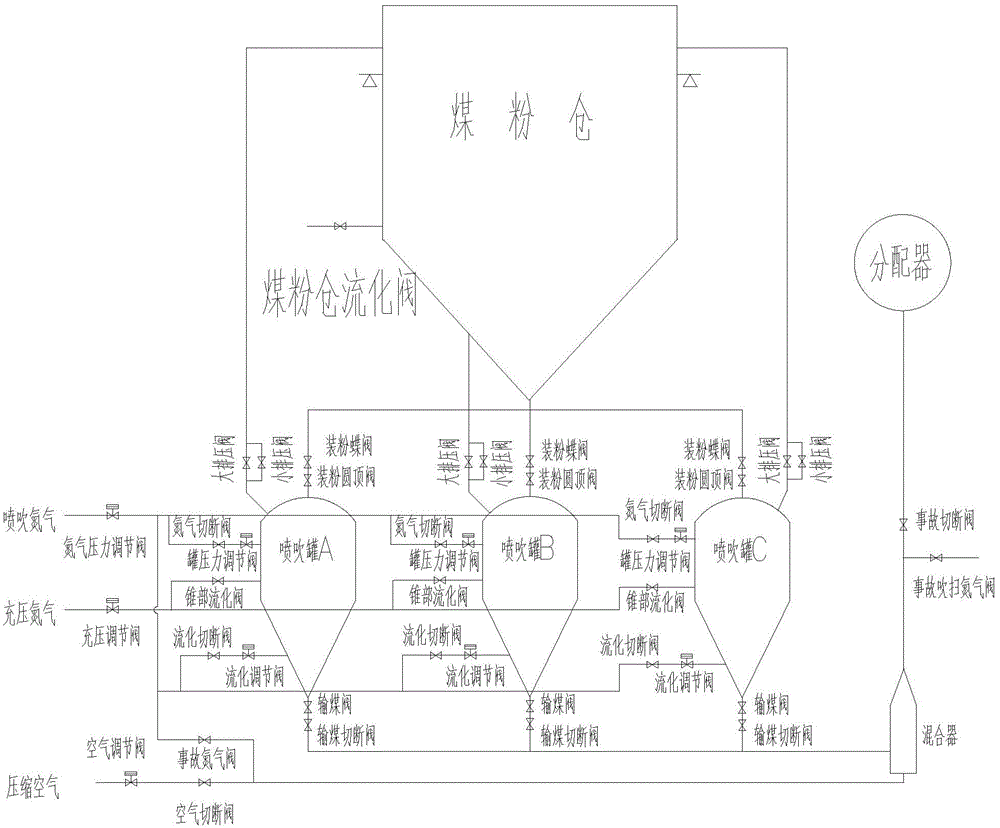

[0023] Taking Nangang No. 3 blast furnace as an example, the volume is 2000m 3 ,Such as figure 1 As shown, three tanks are used in parallel with a single pipeline for direct injection, and the volume of a single injection tank is 38m 3

[0024] The control method of the injection system is divided into several steps: preparation, pressure relief, powder filling, pressure filling, injection, and can pouring. The program controls each part of the injection system to operate as follows:

[0025] Preparation: Set all valves to be under centralized control, open the compressed air cut-off valve, open the compressed air regulating valve to 60%, send air to the distributor, and close the valves connected to the spray tank.

[0026] Pressure relief: open the small pressure relief valve, and open the large pressure relief valve when the internal pressure of the monitoring tank drops to 200Kpa.

[0027] Powder loading: When the pressure in the injection tank drops to 10Kpa, open the ...

Embodiment 2

[0032] The automatic control system of the injection system includes:

[0033] Preparation unit: it is used to set all the valves under centralized control, open the compressed air cut-off valve, open the compressed air regulating valve to 60%, send air to the distributor, and close the valves connected to the spray tank;

[0034] Pressure relief control unit: control the small pressure relief valve and the large pressure relief valve to realize the pressure relief of the blowing tank.

[0035] Specifically: open the small pressure relief valve, and open the large pressure relief valve when the internal pressure of the monitoring tank drops to 200Kpa.

[0036]Powder filling control unit: according to the set conditions, control the fluidization valve of the pulverized coal bin, the powder filling dome valve, and the powder filling butterfly valve to realize the powder filling of the injection tank.

[0037] Specifically: when the pressure in the injection tank drops to 10Kpa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com