A light and small dual-axis photonic crystal fiber optic gyroscope skeleton

A photonic crystal fiber, light and small technology, applied in the direction of Sagnac effect gyroscope, gyroscope/steering sensor equipment, measuring device, etc., can solve the problem that the performance of ordinary optical fiber is greatly affected, the increase of fiber loss, and the increase of fiber loss and other issues, to achieve the effect of reducing material consumption and volume, facilitating installation and debugging, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be further described in detail below with reference to the drawings and embodiments.

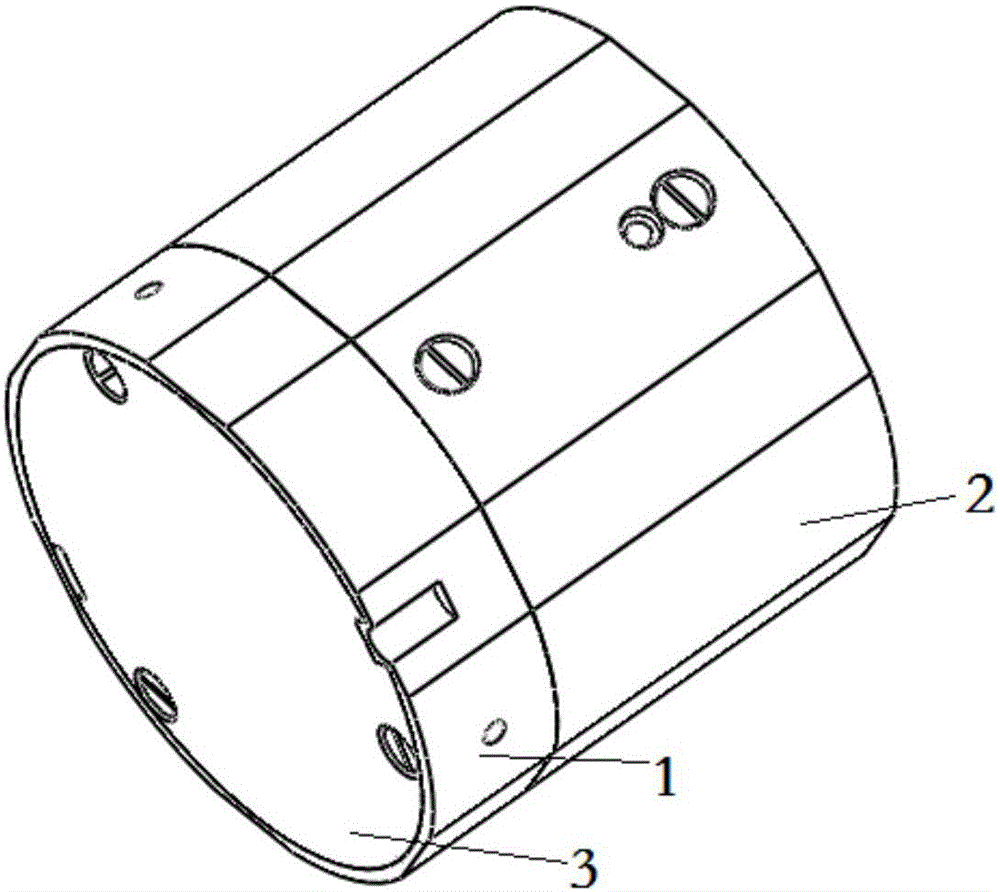

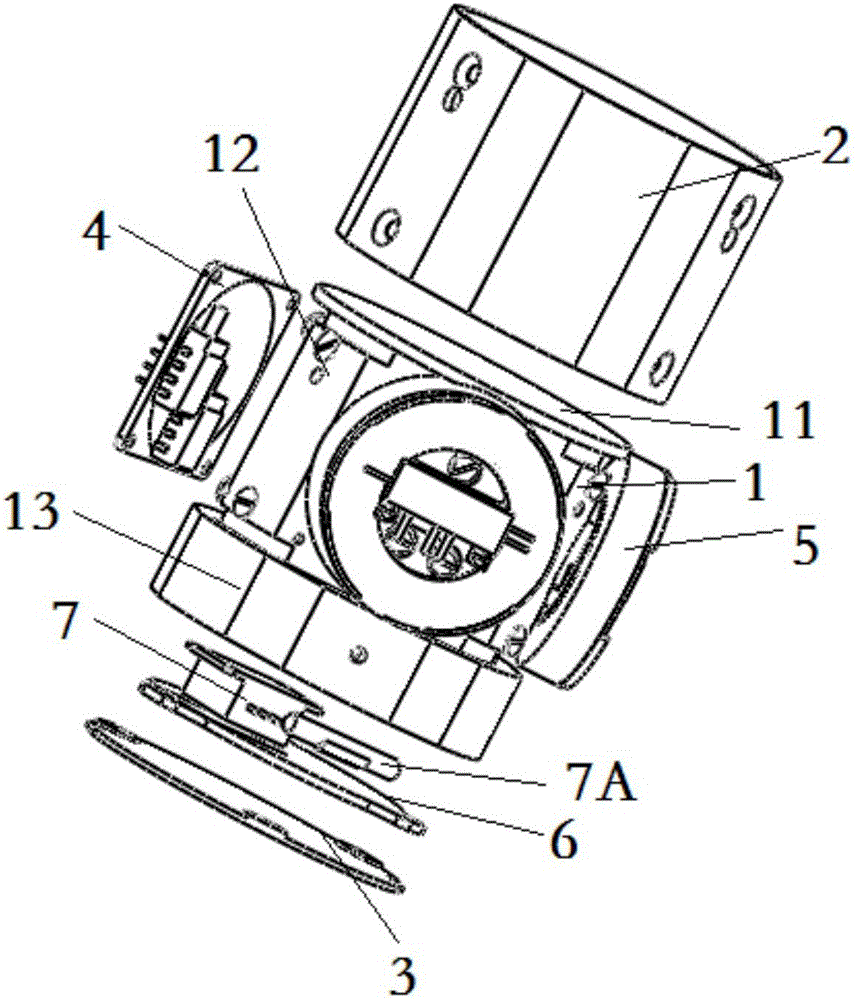

[0081] The present invention is a light and small biaxial photonic crystal fiber gyroscope skeleton, such as figure 1 , Figure 1A As shown, it includes a skeleton body 1, an outer cover 2, a lower cover 3, a front release board 4, a ring assembly 5, a light source board 6 and a light source 7.

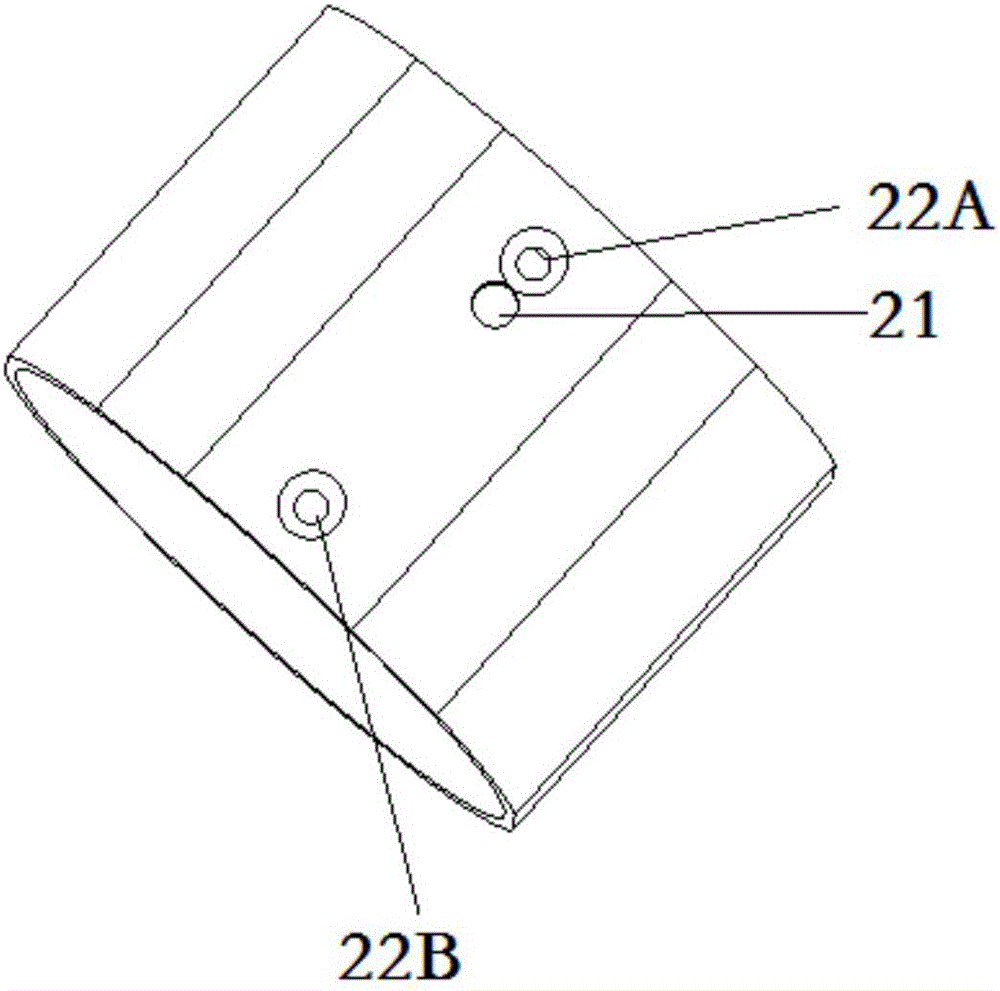

[0082] The outer cover 2 is connected with the threaded holes 12A21 and 12A22 in the middle of the frame body 1 by countersunk screws to achieve a fixed connection; the front plate 4 is installed on the front plate surface 123 in the middle of the frame body 1, and the two fiber ring components are respectively installed on the frame body 1 the ring assembly surfaces 121 and 122 in the middle; the light source plate 6 is installed in the bottom of the skeleton body 1; the lower cover 3 is installed at the lower end of the skeleton body 1.

[0083] Skeleton body 1 such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com