Mixing stirring device of mechanical stirring and source stirring of electromagnetic reverberation chamber and method

A technology of electromagnetic reverberation chamber and mechanical stirring, which is applied in the direction of measuring devices, parts of electrical measuring instruments, measuring electricity, etc., can solve the problems of limited statistical uniformity effect and unsuitable engineering realization, so as to improve the test efficiency and test The effect of repeatability, reduced manual intervention, and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

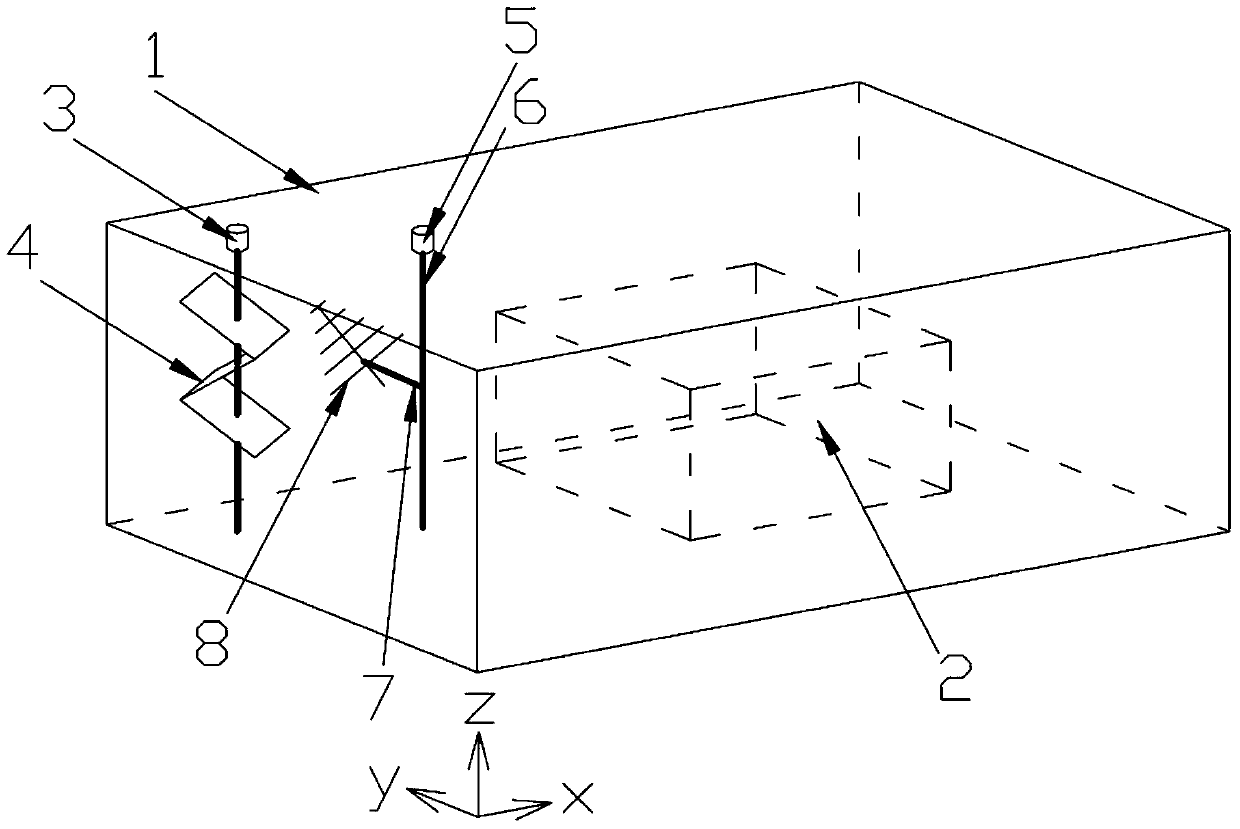

[0049] The present invention provides a mixing and stirring device for mechanical stirring and source stirring of an electromagnetic reverberation chamber, which includes an electromagnetic reverberation chamber 1, and also includes a mechanical stirring assembly and a source stirring assembly arranged on the side wall of the electromagnetic reverberation chamber 1; the mechanical stirring The assembly includes a first motor 3 and a mechanical stirrer 4 connected to the first motor 3; the source stirring assembly includes a second motor 5, a rotating shaft 6 connected to the second motor 5, and a transmitting antenna 8 arranged on the rotating shaft 6; The source stirring assembly also includes an extension arm 7 arranged on the rotating shaft 6 and a transmitting antenna 8 arranged on the extension arm 7; at least one extension arm 7; at least one mechanical stirring assembly; at least one source stirring assembly.

[0050] The invention provides a mixing and stirring method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com