Integrated device for realizing light polarization beam splitting and rotation

An integrated device and optical polarization technology, applied in the field of integrated photonics, can solve the problems of reducing stability, increasing the cost of polarization diversity solutions, and complex processing of integrated polarization rotators, and achieves the effect of wide working wavelength range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

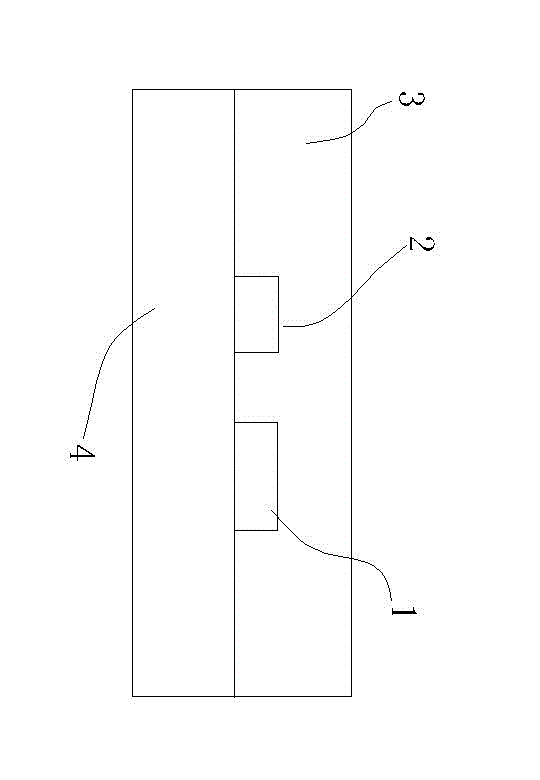

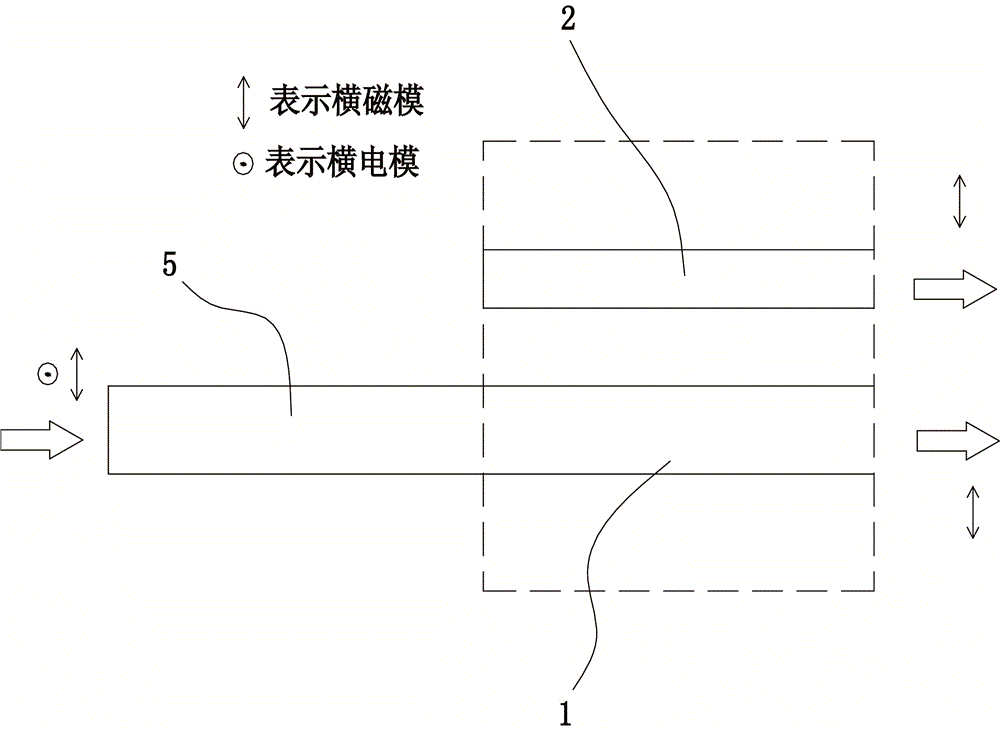

[0020] An integrated device for realizing optical polarization beam splitting and rotation, including two first straight waveguides 1 and second straight waveguides 2 arranged in parallel, the first straight waveguide 1 and the second straight waveguide 2 are made of high refractive index materials, generally should be greater than or equal to 2.8. In this embodiment, silicon is used. An upper cladding layer 3 is arranged above the first straight waveguide 1 and the second straight waveguide 2, and a lower cladding layer 4 is arranged below to form a coupling region, wherein, The refractive index of the upper cladding layer 3 and the lower cladding layer 4 is lower than the refractive index of the first straight waveguide 1 and the second straight waveguide 2, and the refractive index of the upper cladding layer 3 is greater than or smaller than that of the lower cladding layer The refractive index of layer 4, generally the refractive index of the upper cladding layer 3 and the...

Embodiment 2

[0024] An integrated device for realizing optical polarization beam splitting and rotation, including two first straight waveguides 1 and second straight waveguides 2 arranged in parallel, the first straight waveguide 1 and the second straight waveguide 2 are made of high refractive index materials, generally should be greater than or equal to 2.8. In this embodiment, silicon is used. An upper cladding layer 3 is arranged above the first straight waveguide 1 and the second straight waveguide 2, and a lower cladding layer 4 is arranged below to form a coupling region, wherein, The refractive index of the upper cladding layer 3 and the lower cladding layer 4 is lower than the refractive index of the first straight waveguide 1 and the second straight waveguide 2, and the refractive index of the upper cladding layer 3 is greater than or smaller than that of the lower cladding layer The refractive index of layer 4, generally the refractive index of the upper cladding layer 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com