Nano-particle system and preparation system and application of nano-particle system

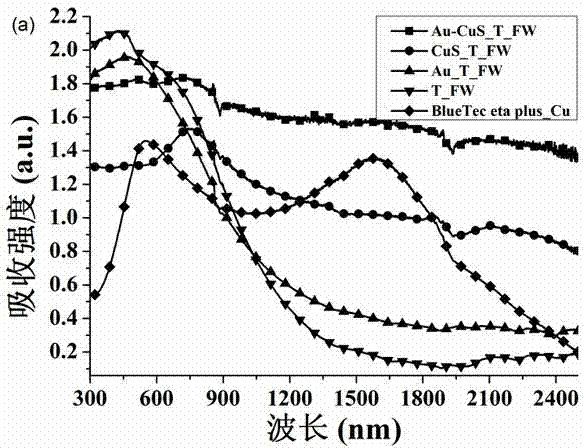

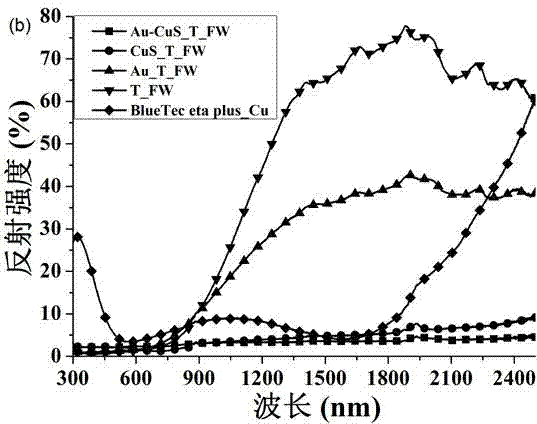

A technology of nanoparticles and butterfly wings, applied in the field of preparation of light energy absorbers, to achieve remarkable photoelectric conversion performance, high-efficiency light-to-heat conversion performance, high absorption and anti-reflection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

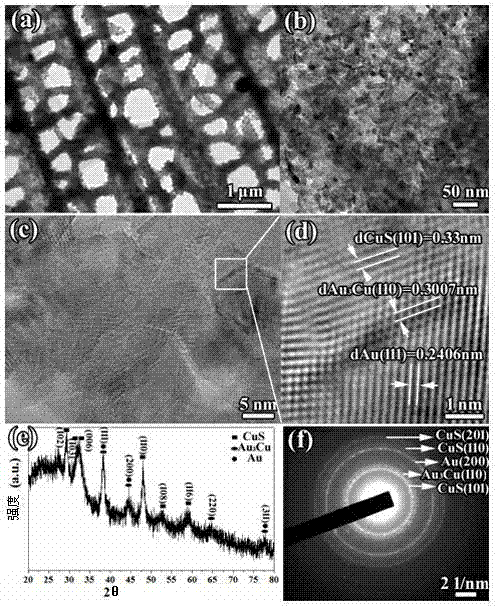

Method used

Image

Examples

Embodiment 1

[0052] The preparation method of the Au-CuS nanoparticle system of this embodiment comprises the following steps:

[0053] (1) Select the forewing of Papilion butterfly as the butterfly wing with anti-reflection microstructure;

[0054] (2) Perform the following pre-treatment and activation treatment on the forewings of the selected Papilionidae: first, soak the wings in absolute ethanol for 30 minutes, and then wash them with deionized water; then soak the wings in 15vol% HNO 3 Put it in the solution for 2 hours, take it out and wash it; then soak the butterfly wings in 40% ethylenediamine absolute ethanol solution for 6 hours, then take it out, and wash it several times with deionized water; the above steps are used to remove pigments and impurities , and improve its surface adsorption properties;

[0055] (3) Deposition of Au nanoparticles: The activated butterfly wings were immersed in the chloroauric acid precursor solution at a constant temperature of 30°C for 4 hours,...

Embodiment 2

[0070] The preparation method of the Au-CdS nanoparticle system of the present embodiment comprises the following steps:

[0071] (1) Select the forewing of Papilion butterfly as the butterfly wing with anti-reflection microstructure;

[0072] (2) Perform the following pretreatment and activation treatment on the selected forewings of Papilionidae: first, soak the wings in absolute ethanol for 15 minutes, and then wash them with deionized water; then soak the wings in 5vol% HNO 3 Put it in the solution for 2 hours, take it out and wash it; then soak the butterfly wings in 10% ethylenediamine absolute ethanol solution for 6 hours, then take it out and wash it several times with deionized water; the above steps are used to remove pigments and impurities , and improve its surface adsorption properties;

[0073] (3) Deposition of Au nanoparticles: immerse the activated butterfly wings in the chloroauric acid precursor solution at a constant temperature of 15 °C for 10 h, then ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com