Low-temperature laminated sludge dehydrating and drying box

A technology of sludge dehydration and lamination, which is applied in the directions of dehydration/drying/thickened sludge treatment, energy wastewater treatment, etc., and can solve the problems of not considering the cost of sludge treatment and disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

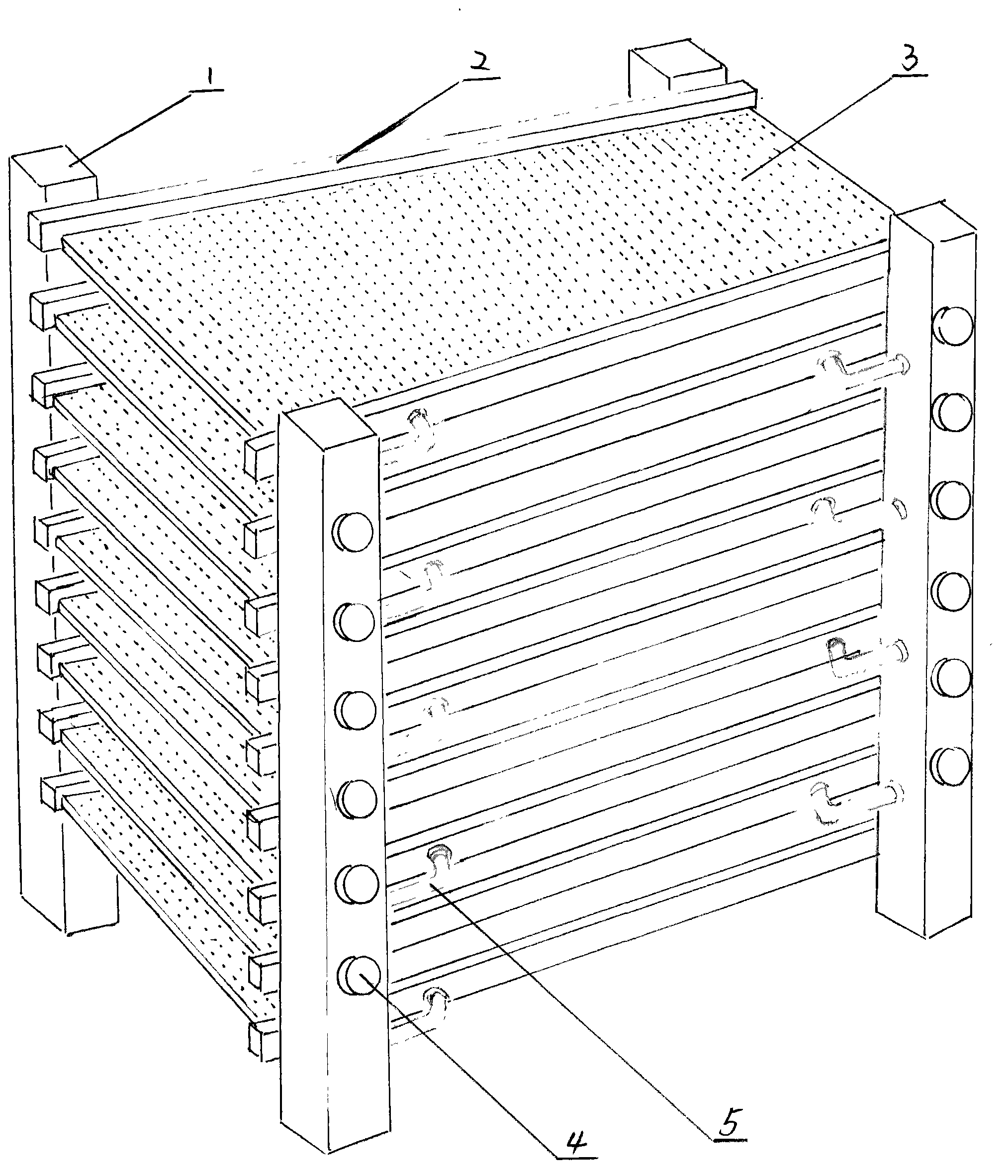

[0029] The design concept of the present invention is: 100 blankets will not dry for a few days when stacked together. If 100 blankets are divided into 100 layers, they will all dry in a few hours. Now we divide 1 cubic meter of sludge into 100 square meters When the area is less than one meter, the purpose of rapid dehydration and drying can also be achieved. At the same time, the hot blowing technology is used to accelerate the evaporation of sludge, and the sludge with a water content of about 80% is reduced to less than 30% within a certain period of time to achieve sludge resource utilization.

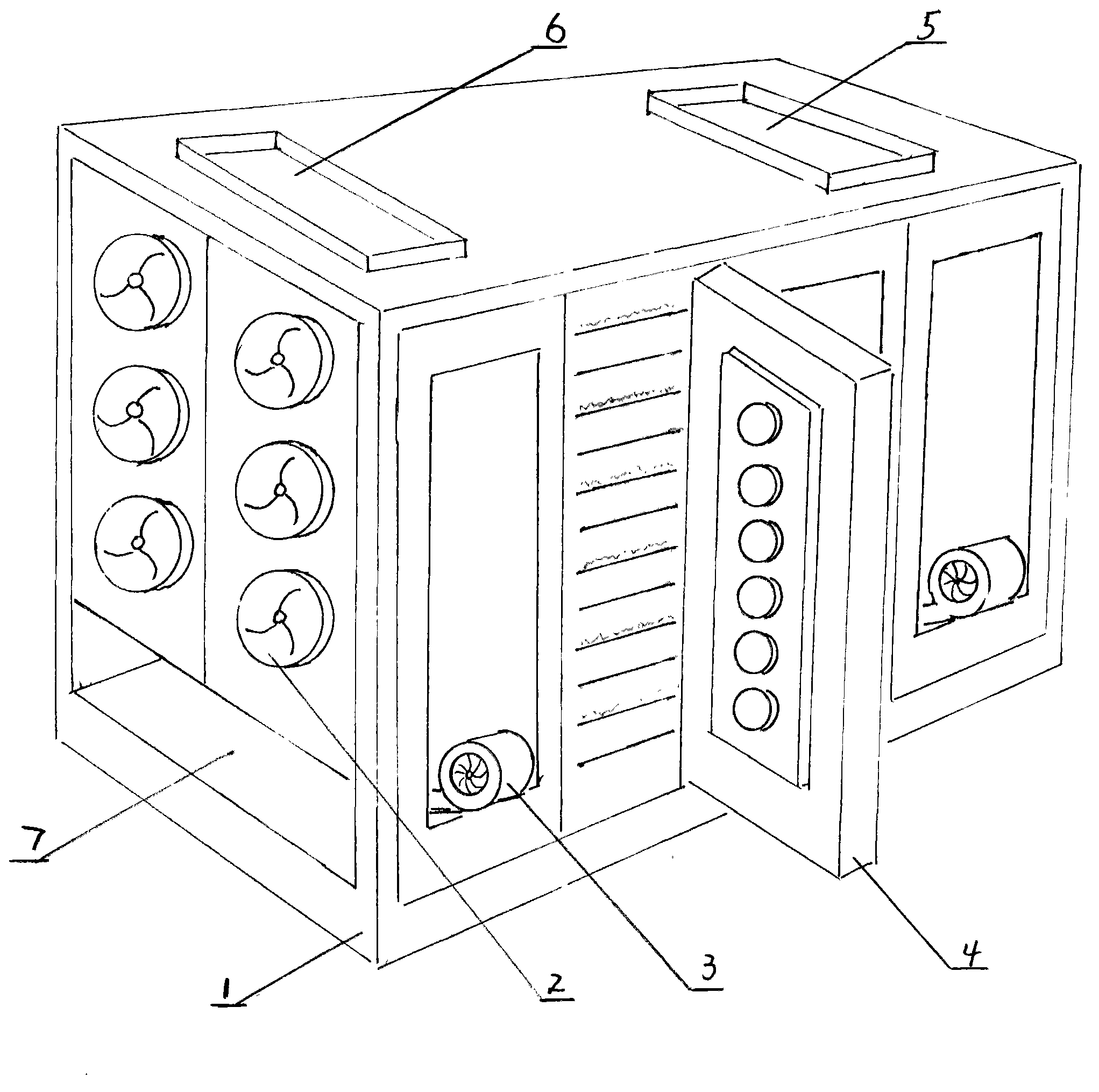

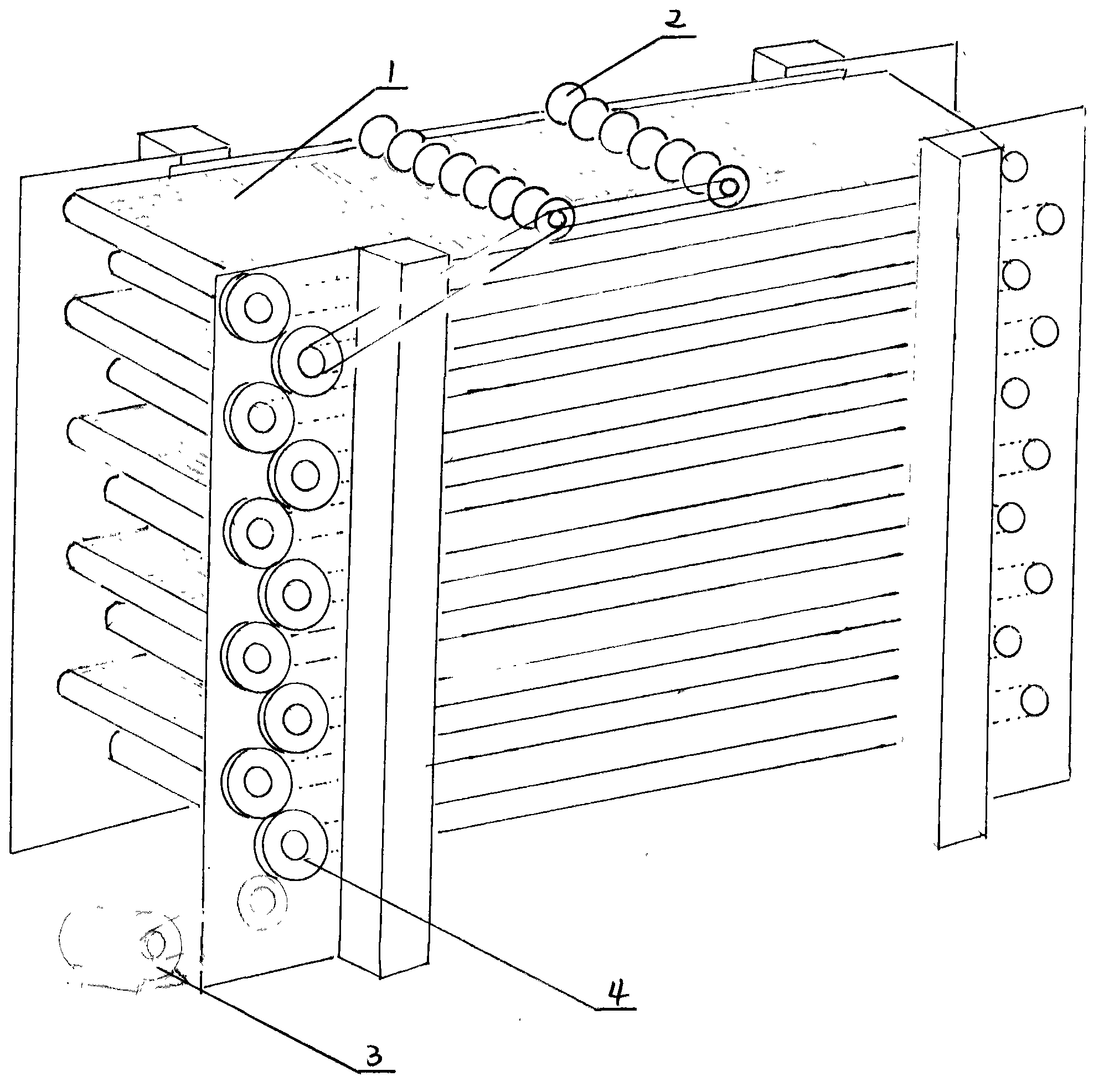

[0030] The specific implementation is as attached figure 1 In the shown embodiment, the sludge enters the first conveyor belt of the low-temperature laminated sludge dewatering and drying tank from the feed port. by attaching image 3 Two sets of wheeled leveling wheels in the middle level the lumped sludge to a thickness of 10-20mm, and fall to the next layer as the conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com