Method for improving CIGS cell efficiency after laser scribing by vacuum adsorption positioning

A vacuum adsorption and laser scribing technology, which is applied to circuits, electrical components, glass manufacturing equipment, etc., can solve the problems of not being able to grasp the glass and damage the film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

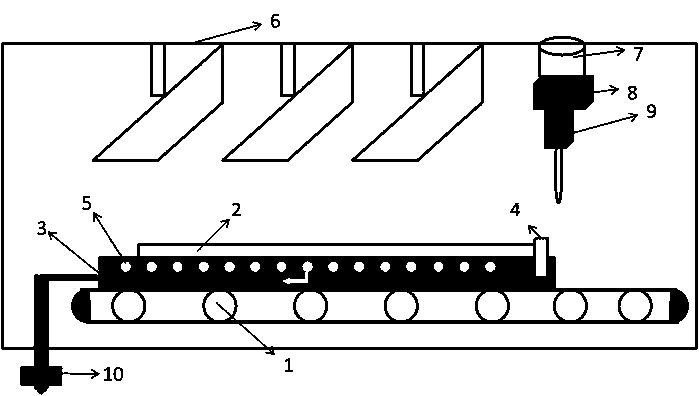

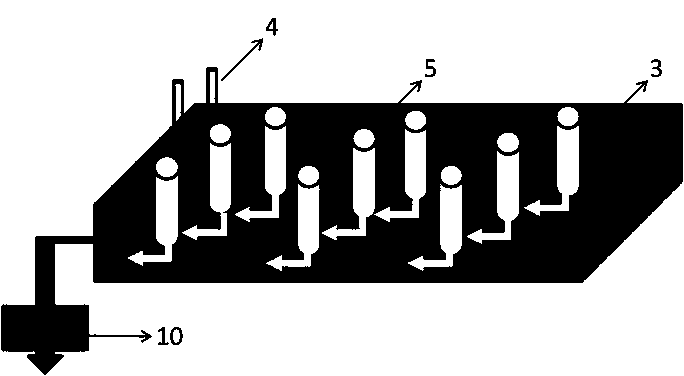

[0008] Hereby the present invention is cooperated with accompanying drawing, detailed description is as follows: figure 1 It is a schematic diagram of the Laser laser machine for improving the efficiency of CIGS cells after laser scribing by vacuum adsorption positioning according to the present invention. It can be seen from the figure that the CIGS glass 2 is placed on the vacuum adsorption platform 3 with the film facing upward as a tangent, and then the glass is pushed Position on Pin 4, and then the vacuum pump 10 under the vacuum adsorption platform will start to absorb the glass through the vacuum hole 5. The adsorption pressure is about several kpa. After the adsorption is completed, the glass will not move at all. , that is, the accuracy can achieve that there will be no overlapping or crossing of the scribed lines. After the adsorption is completed, the Laser laser scribing can be started. The glass is attached to the platform for scribing, and the scribing is dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com