Method for rapidly and continuously carbonizing agricultural straws

A straw and fast technology, which is applied in the field of continuous and rapid carbonization of agricultural straw, can solve the problems of inability to carbonize straw mixture and slow carbonization speed, and achieve the effects of saving procedures, saving energy consumption and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: carbonization of rape straw

[0024] Collect rape stalks, dry them in the sun, cut the rape stalks into small pieces below 10cm, dehumidify them on the top of the carbonization furnace, and then enter the pyrolysis pool. The pyrolysis temperature in the decomposing pool is 350°C, and the pyrolysis time is 70 minutes. After the pyrolysis is completed, the charcoal is stuffed. The charcoal stuffing time is 10 minutes, and then cooled to 100-200°C to produce charcoal. Each ton of rape straw (dry weight) can get 300kg of carbonized material, 210kg of vinegar liquid, 18kg of tar, and 650m of combustible gas 3 .

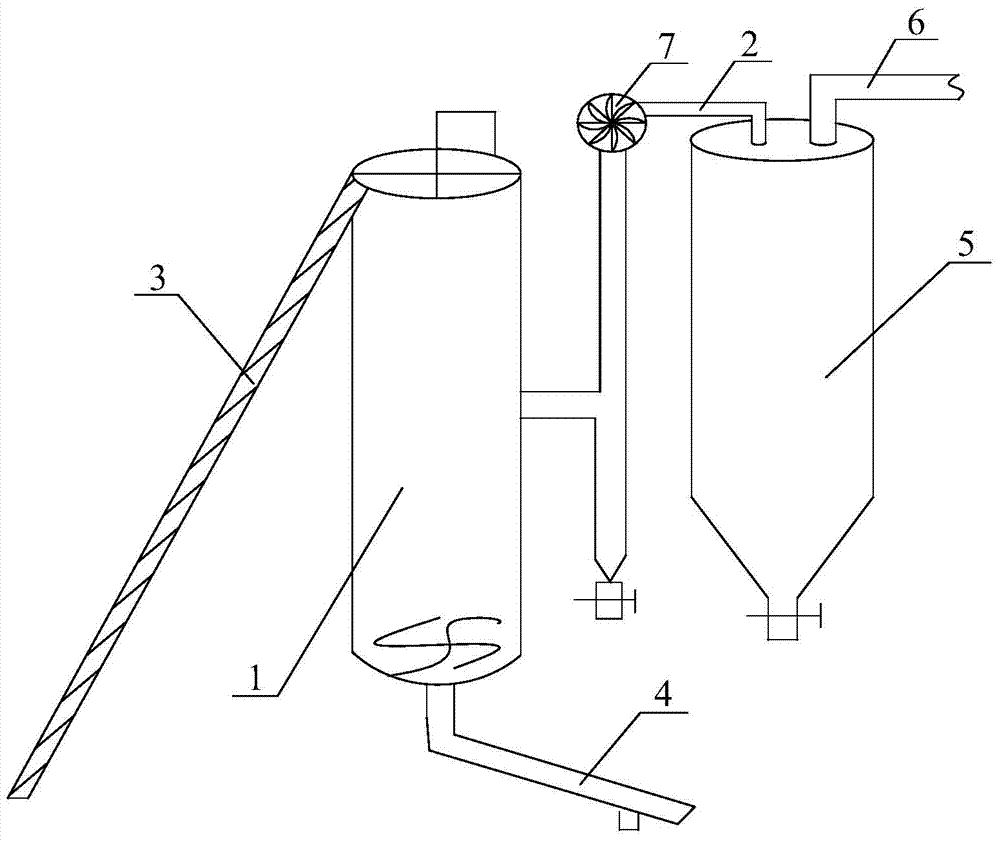

[0025] The carbonization furnace of the present invention can use the application number 201320368810.3 as a crop straw carbonization device, figure 1 A schematic structural diagram of the device is shown, and the crop straw carbonization device is mainly composed of a pyrolysis tank 1, which is a tower-type pyrolysis tank. In order to facilitate in...

Embodiment 2

[0026] Embodiment 2: the carbonization of edible mushroom residue

[0027] Collect edible fungus slag, dry it in the sun, cut the edible fungus slag into small pieces below 10cm, dehumidify on the top of the carbonization furnace, and then enter the pyrolysis pool. Yes; the pyrolysis temperature in the pyrolysis pool is 380°C, and the pyrolysis time is 70 minutes. After the pyrolysis is completed, the charcoal is stuffed. The charcoal stuffing time is 10 minutes, and then cooled to 100-200°C to produce charcoal. For each ton of edible fungus residue (dry weight), 360kg of carbonized material, 230kg of vinegar liquid, 8kg of tar, and 600m of combustible gas can be obtained. 3 .

Embodiment 3

[0028] Example 3: Carbonization of forestry residues

[0029] Collect forestry residues, dry them in the sun, cut the forestry residues into small pieces below 10cm, dehumidify them on the top of the carbonization furnace, and then enter the pyrolysis pool. Yes; the pyrolysis temperature in the pyrolysis pool is 300°C, and the pyrolysis time is 70 minutes. After the pyrolysis is completed, the charcoal is stuffed. The charcoal stuffing time is 10 minutes, and then cooled to 100-200°C to produce charcoal. For each ton of forestry residues (dry weight), 330kg of carbonized material, 250kg of vinegar liquid, 30kg of tar, and 700m of combustible gas can be obtained 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com