A device for electrohydrogenating soybean oil in a supercritical CO2 state

An electric hydrogenation of soybean oil, supercritical technology, applied in electrolysis components, electrolysis process, fatty acid hydrogenation, etc., can solve problems such as difficult operation, adverse effects, high temperature of production conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

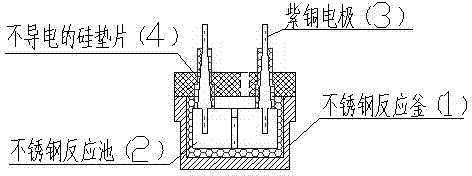

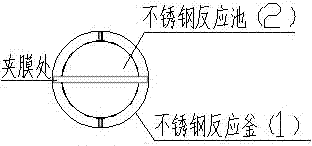

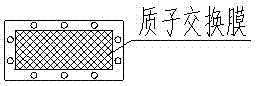

[0009] Specific implementation mode one: combine figure 1 , figure 2 , image 3 Illustrate the present invention, the present invention as figure 1 The shown includes a stainless steel reaction kettle (1), a stainless steel reaction tank (2), a copper electrode (3), and a non-conductive silicon gasket (4); the stainless steel reaction tank (2) is located in the stainless steel reaction tank (1), and the exchange membrane (such as image 3 ) separated from the middle, such as figure 2 shown; the copper electrodes (3) are respectively inserted into the stainless steel reaction pool (2), located on the proton exchange membrane (such as image 3 ) on both sides, and it is separated from the stainless steel wall of the stainless steel reactor (1) by a non-conductive silicon gasket (4) to prevent short circuit. The catalyst is attached to the proton exchange membrane, and the mixed solution of soybean oil and sodium formate and sulfuric acid are respectively loaded into both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com