A push-up mechanism and a lithography device with the push-up mechanism

A technology of push pins and driving devices, which is applied in the direction of photolithography exposure devices, microlithography exposure equipment, etc., can solve the problems of low product yield, long handover time, broken silicon wafers/glass substrates, etc., to improve production efficiency and reduce handover time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

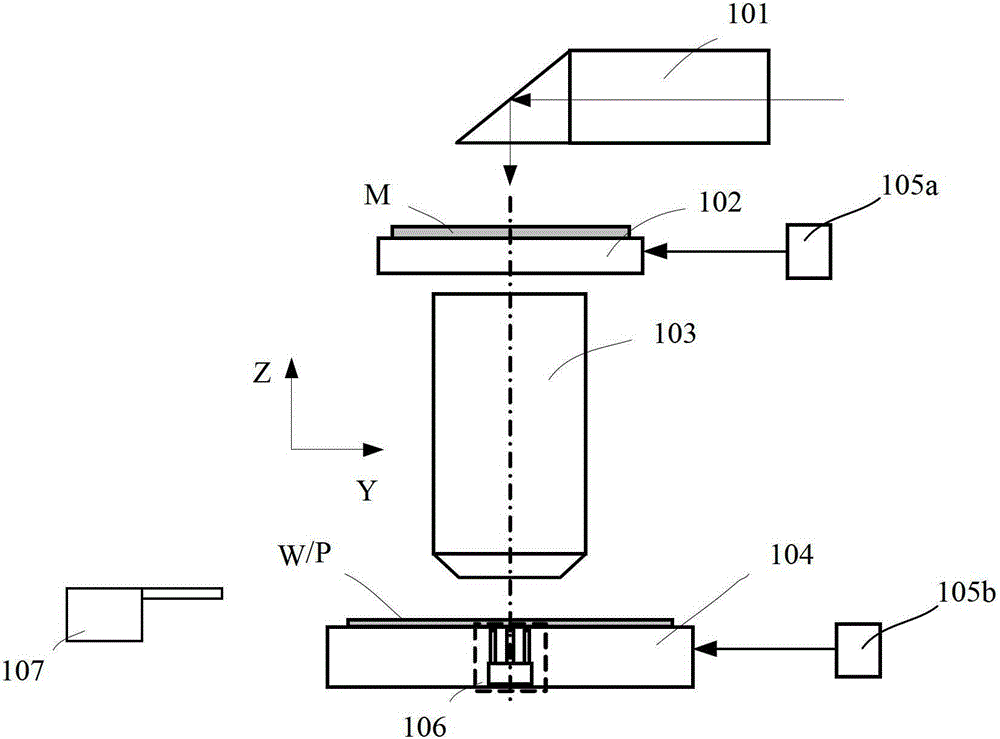

[0022] see image 3 , this embodiment firstly describes the structure of the photolithography machine schematically. As can be seen from the figure, the lithography machine mainly includes an illumination system 101, a mask table 102, a projection objective lens 103, a workpiece table 104, laser interferometers 105a, 105b, an ejector mechanism 106, and a wafer / substrate transfer system 107. The illumination system 101 provides the exposure light source for the exposure device, the mask stage 102 supports and positions the reticle M, and the projection objective lens 103 provides the exposure field of view, exposing the pattern on the reticle M on the silicon wafer / glass substrate W / P (Wafer / Plate ), the workpiece table 104 carries the silicon wafer / glass substrate W / P, and provides support and positioning functions for the silicon wafer / glass substrate W / P. Laser interferometers 105 a , 105 b provide position signals for precise motion control of mask table 102 and workpiece ...

Embodiment 2

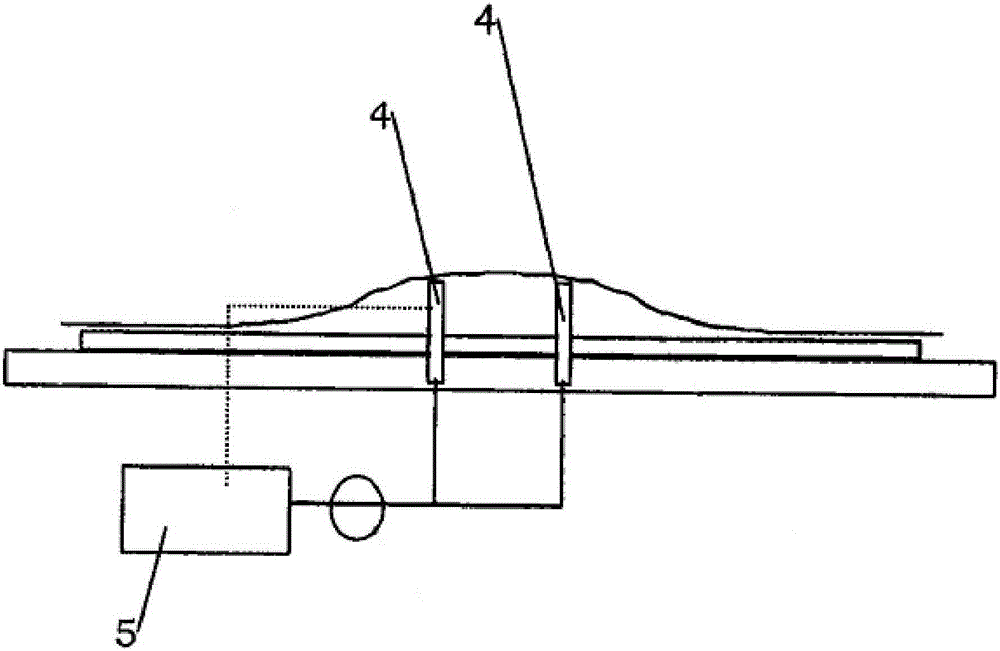

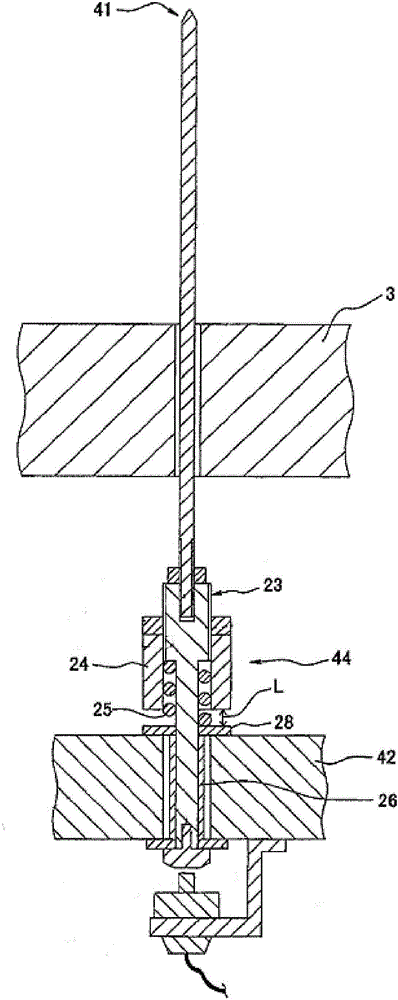

[0027] Figure 5 It is a structural schematic diagram of Embodiment 2 of the ejecting mechanism of the present invention. By several sets of reed mechanisms 301a, 301b ( Figure 5 Only two groups are drawn) to form an elastic damping device, so that the entire ejector mechanism joint / plate part has a certain stiffness K and damping C in the vertical direction, which provides protection for the silicon wafer / glass substrate when the piece / plate is unloaded, and at the same time can Reduce handover time and increase productivity.

[0028] Figure 6a , Figure 6b , Figure 6c It is a schematic structural diagram of three embodiments of the reed mechanism 301, which respectively include the connecting plate fixed end 401 / 501 / 601 fixedly connected to the connecting plate 203, and the driving device (in this embodiment, the voice coil motor 207a, 207b ) driving fixed end 403 / 503 / 603, and a flexible reed connected between the connecting plate fixed end 401 / 501 / 601 and the drivin...

Embodiment 3

[0033] The ejecting mechanism described in the second embodiment uses several groups of reed mechanisms 301a, 301b as elastic damping devices. In this embodiment, the reeds can also be replaced with elastic damping plates with a certain stiffness K and damping C, such as Rubber sheet 701, such as Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com