Manufacturing method of surface mount coil inductor

A coil inductance, surface mount technology, applied in the direction of inductance/transformer/magnet manufacturing, inductors, fixed inductors, etc., can solve the problems of unstable electrical connection performance of coil inductance, complicated manufacturing process, increased manufacturing cost, etc., to achieve Reduced manufacturing steps, simple manufacturing process, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

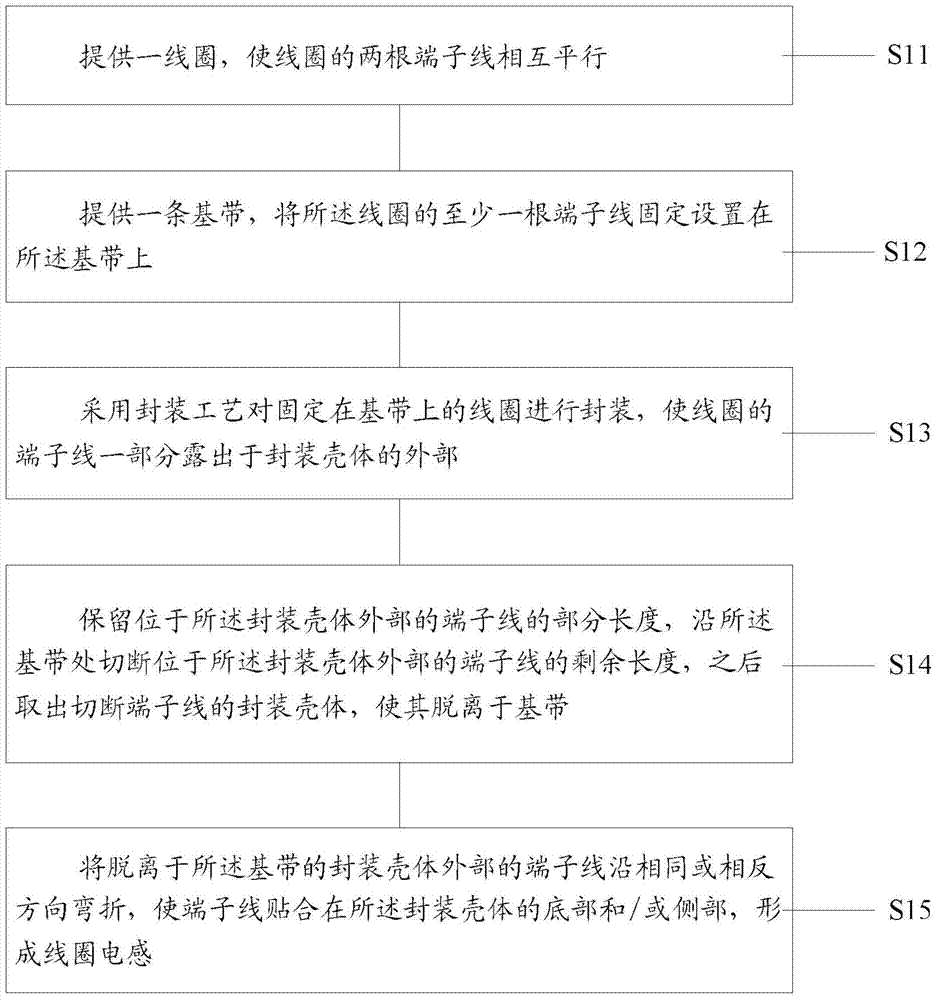

[0050] Please refer to figure 1 , 1A To 11, the manufacturing method of the surface mount coil inductance of the present embodiment 1 comprises the following steps:

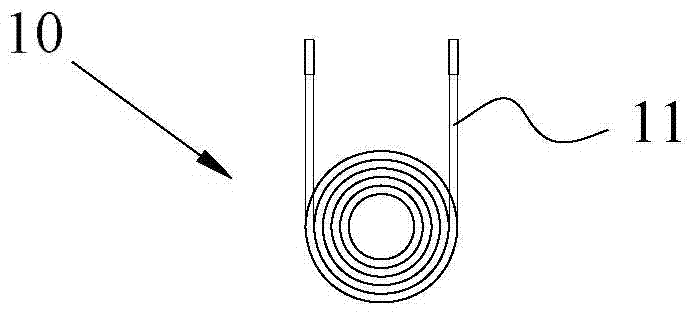

[0051] Step S11, please refer to Figure 1A , providing a coil 10 so that the two terminal wires 11 of the coil 10 are parallel to each other;

[0052] Step S12, please refer to Figures 1B to 1C , providing a base band 20, and fixing at least one terminal wire 11 of the coil 10 on the base band 20;

[0053] Step S13, please refer to Figure 1D , using a packaging process to package the coil 10 fixed on the base tape 20, so that a part of the terminal wire 11 of the coil 10 is exposed outside the package casing 30;

[0054] Step S14, please refer to Figure 1D , 1E, reserving a part of the length of the terminal wire 11 located outside the packaging case 30, cutting off the remaining length of the terminal wire 11 located outside the packaging case 30 along the base tape 20, and then taking out the termina...

Embodiment 2

[0061] Please refer to figure 2 , 2A Up to 2J, the manufacturing method of the surface mount coil inductor of the second embodiment is basically the same as that of the first embodiment, both of which are made by using the baseband 20 to fix the terminal wire 11 of the coil 10, including the following steps:

[0062] Step S21, please refer to Figures 2A to 2B , providing a coil 10, expanding each terminal wire 11 of the coil 10 so that the two terminal wires 11 are parallel to each other or located on the same center line;

[0063] Step S22, please refer to Figures 2C to 2D , please provide two base strips 20 parallel to each other, and fix at least one terminal wire 11 of the coil 10 on at least one of the base strips 20;

[0064] Step S23, please refer to Figure 2E , using a packaging process to package the coil 10, so that a part of each terminal wire 11 of the coil 10 is exposed outside the package casing 30;

[0065] Step S24, please refer to Figure 2F , keep p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com