Semi-automatic argon-arc welding method for bimetal composite pipes

A bimetallic composite pipe, argon arc welding technology, applied in welding equipment, metal processing, arc welding equipment and other directions, can solve the problems of welding stress concentration in the sealing welding part, high labor intensity of workers, large welding heat input, etc. Prevent welding stress concentration, reduce labor intensity of workers, and reduce the effect of welding joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

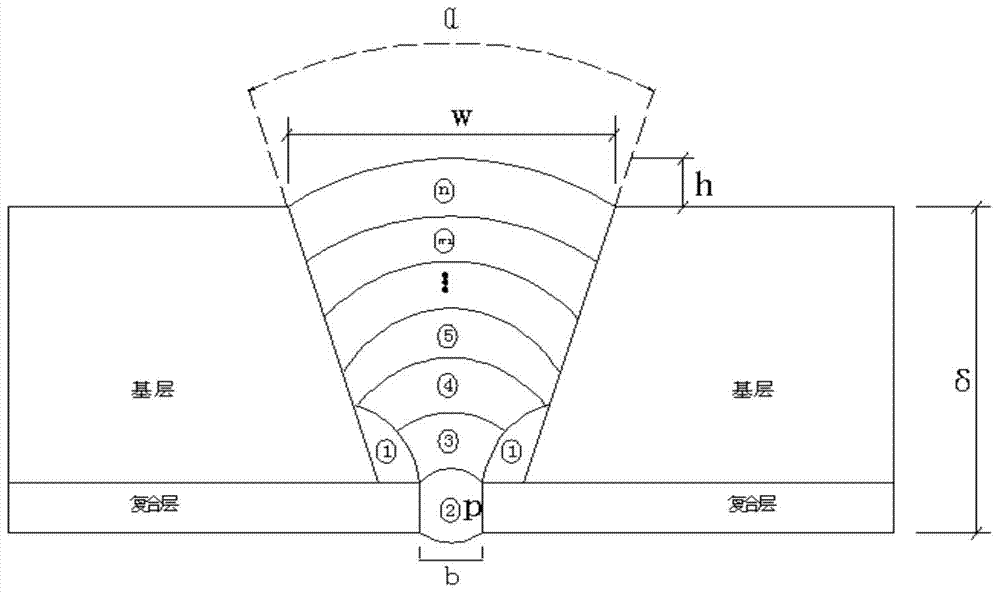

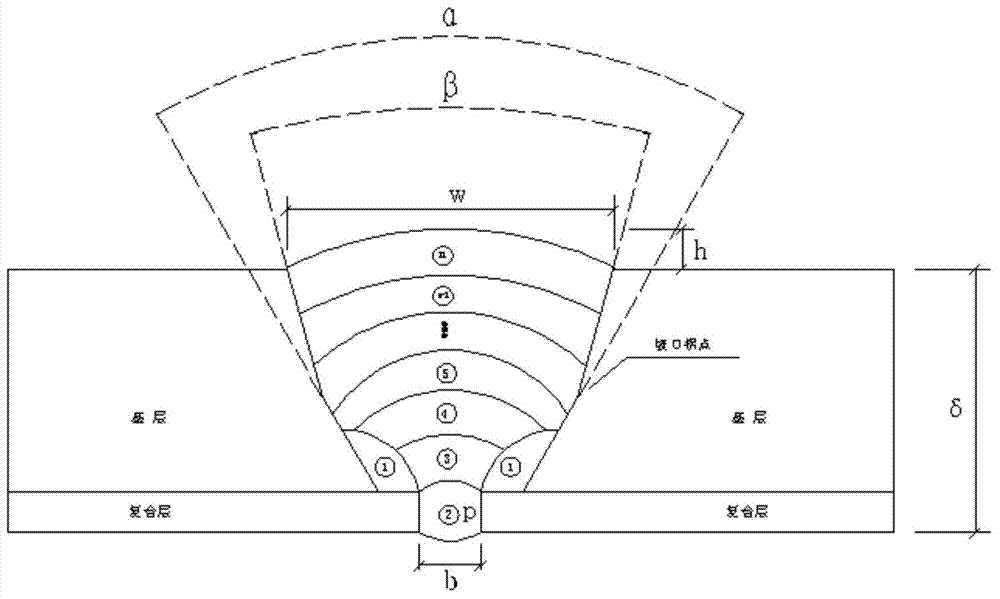

[0041] The first step: groove processing. see figure 1 , the material of the steel pipe is SFG-L415QB-BS316L steel, the diameter of the pipe is ¢355.6×(11+2) mm, the wall thickness δ of the steel pipe to be welded is 11+2 mm, the groove type is V-shaped groove, and the slope is mechanically processed. The end surface of the mouth is processed flat, uniform and smooth. Relevant parameters of the groove after processing: the groove angle α is 55°-65°, the weld gap b between the composite layers of the steel pipe is 2.5-3.5mm, and the blunt edge p of the composite layer is 0.8-1.5mm.

[0042] The second step: nozzle cleaning. Remove the rust, slag, grease, paint and other harmful substances that affect the welding quality on the surface of the welded pipe nozzle, and use mechanical methods to polish the inner and outer surfaces of the nozzle within 50mm on both sides of the groove to a metallic luster.

[0043] The third step: nozzle pairing. Use inner counterparts to align t...

Embodiment 2

[0057] The first step: groove processing. see figure 1 , the material of the steel pipe is SFG-L415QB-BS316L steel, the pipe diameter is ¢508×(16+2) mm, the wall thickness δ of the steel pipe to be welded is 16+2 mm, the groove type is V-shaped groove, and the slope is machined by mechanical processing. The end surface of the mouth is processed flat, uniform and smooth. Relevant parameters of the processed groove: the groove angle α is 55°-60°, the weld gap b between the steel pipe composite layers is 2.5-3.5mm, and the blunt edge p of the composite layer is 0.8-1.5mm.

[0058] The second step: nozzle cleaning. Remove the rust, slag, grease, paint and other harmful substances that affect the welding quality on the surface of the welded pipe nozzle, and use mechanical methods to polish the inner and outer surfaces of the nozzle within 50mm on both sides of the groove to a metallic luster.

[0059] The third step: nozzle pairing. Use inner counterparts to align the pipe nozz...

Embodiment 3

[0073] The first step: groove processing. see figure 1 , the material of the steel pipe is SFG-L415QB-BS316L steel, the pipe diameter is ¢323.9×(10+2) mm, the wall thickness δ of the steel pipe to be welded is 10+2 mm, the groove type is V-shaped groove, and the slope is mechanically processed. The end surface of the mouth is processed flat, uniform and smooth. Relevant parameters of the processed groove: the groove angle α is 60°, the weld gap b between the composite layers of the steel pipe is 3.0-3.5mm, and the blunt edge p of the composite layer is 0.8-1.5mm.

[0074] The second step: nozzle cleaning. Remove the rust, slag, grease, paint and other harmful substances that affect the welding quality on the surface of the welded pipe nozzle, and use mechanical methods to polish the inner and outer surfaces of the nozzle within 50mm on both sides of the groove to a metallic luster.

[0075] The third step: nozzle pairing. Use inner counterparts to align the pipe nozzles. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove angle | aaaaa | aaaaa |

| Groove angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com