Die-cutting process and die-cutting production equipment for abrasive paper and cloth

A sandpaper cloth and cutting technology, which is applied in metal processing and other directions, can solve the problems of waste and defective products, low work efficiency, and uneven edge size, and achieve the effects of safe and convenient operation, high work efficiency, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

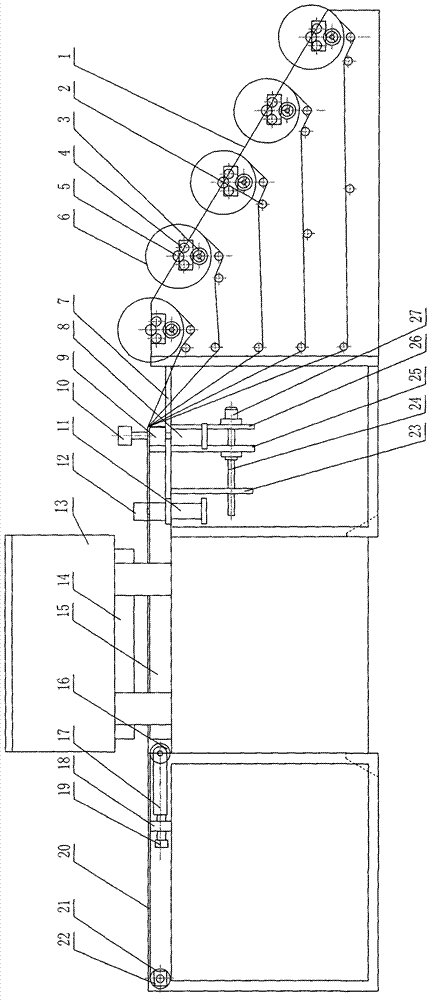

[0014] The present embodiment is a kind of sandpaper cloth die-cutting cutting process, carries out according to the following steps:

[0015] (1) Put the whole roll of sandpaper cloth 6 into the air expansion shaft 5 and place it on the bracket 1, rotate the screw to adjust the hand wheel 3, turn the air expansion shaft 5 for axial fine-tuning, and correct the sand paper cloth 6, the sand paper cloth 6 Divided into 5 routes, merged to the feed port with the lead roller 2.

[0016] (2) After the sandpaper cloth 6 enters the feed port, the cylinder I8 automatically presses down, and presses the 5 layers of sandpaper cloth 6 stacked together by the feeding upper pressing plate 10 and the feeding lower pressing plate 9, when the fixed pressing plate 12 is unloaded When automatically rising, the servo motor II27 starts to work, drives the ball screw 24 to rotate, and at the same time drives the movable plate screw nut 25 to rotate, so that the feeding lower pressing plate 9 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com