Azimuth tugboat with oil slick recovery function

A technology of oil slick recovery and full rotation, which is applied in the direction of tugboats, etc., can solve the problems of delaying the best time, low utilization rate, waste of investment, etc., and achieve the effects of improving oil recovery efficiency, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

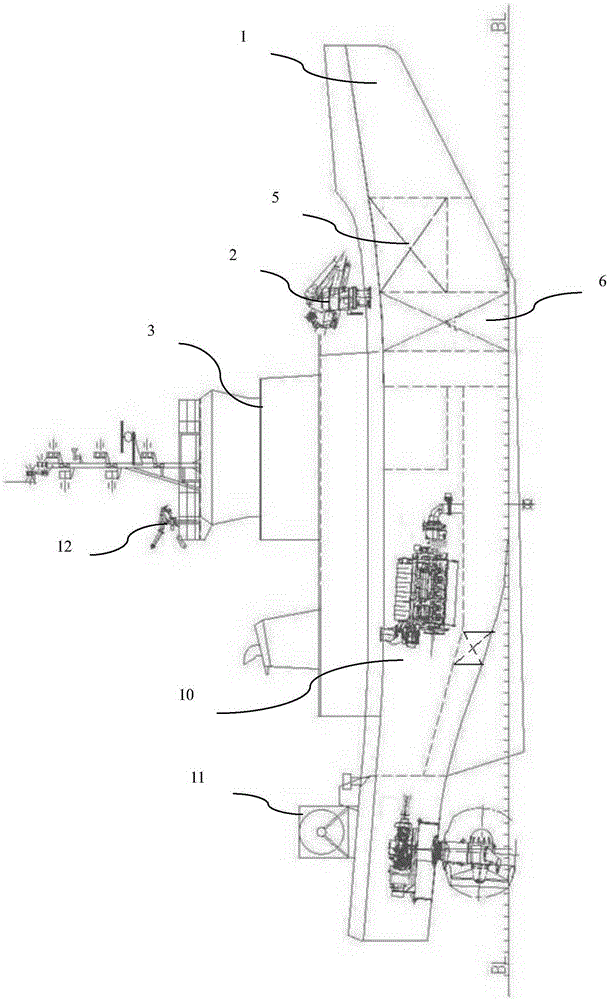

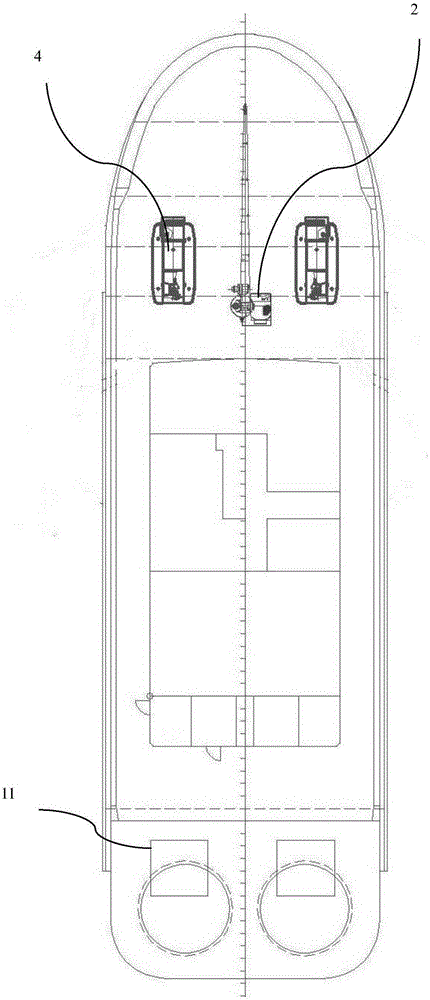

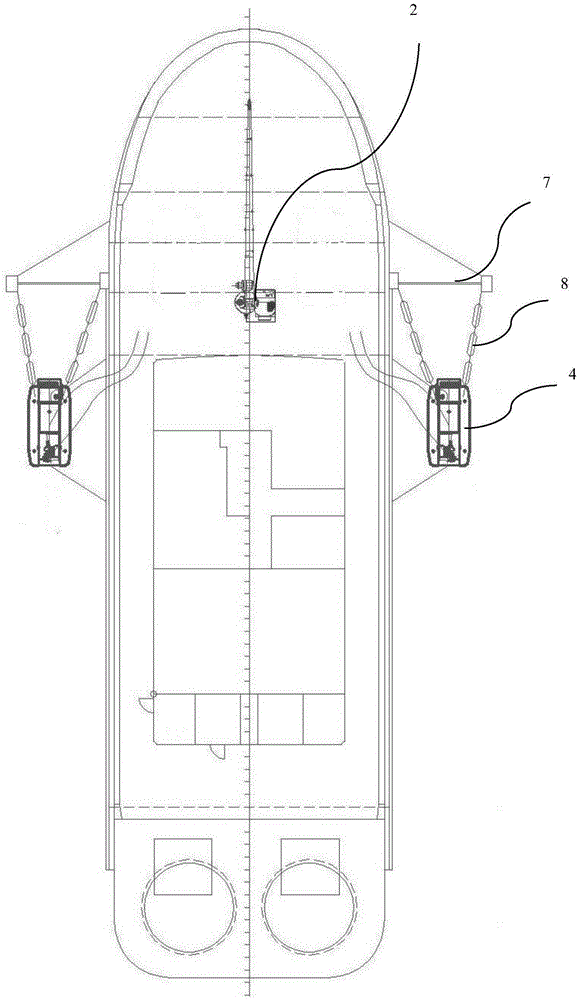

[0013] Such as figure 1 , 2 As shown, the main propulsion system of the full-turn tugboat with oil slick recovery function in the present invention adopts a propulsion system with two full-turn rudders and propellers. The main deck of the whole ship is divided into seven compartments by six watertight transverse bulkheads, including pump room 5, oil slick recovery compartment 6, and engine room 10.

[0014] On the main deck in front of the main deckhouse 3, the ship is equipped with a telescopic crane 2 with a safe working load of 2t, a lifting height of 25m, a lifting speed of 15m / min, a turning angle of 360°, and an operating radius of 3m to 10m. It is not only used to handle the loading and unloading of marine cargo, but more importantly, in the present invention, it is used to put the oil skimmer 4 into the water to work and lift it. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com