Anti-ultraviolet method for cotton fibers

An anti-ultraviolet and cotton fiber technology, applied in fiber treatment, plant fiber, textiles and papermaking, etc., can solve problems such as pollution, affecting the anti-ultraviolet effect of cotton fabrics, affecting the appearance of fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

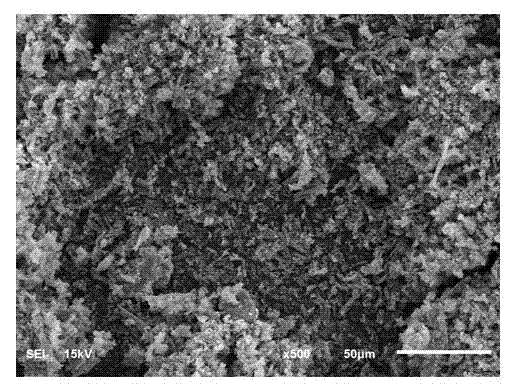

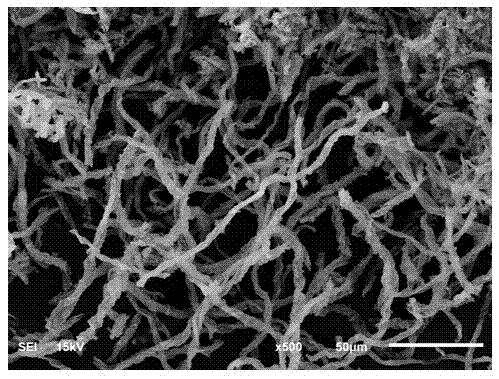

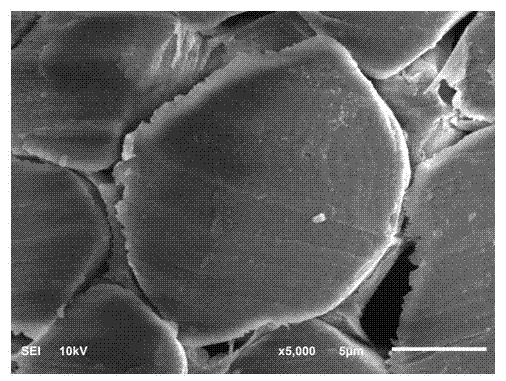

Image

Examples

Embodiment 1

[0036] According to the above process steps: select 5g of long-staple cotton as the cotton fiber to be treated with UV resistance, weigh 0.25g of butyl titanate and mix with 250ml of absolute ethanol, stir evenly to prepare a sol solution with a concentration of 1g / L, and mix 5g of cotton The fibers were immersed in 150ml of the prepared sol solution, and stood at 20°C for 10min. The cotton fiber after soaking is rolled, and the rolling pressure is 0.2MP. The cotton fibers after padding were subjected to steam treatment under steam at 60°C for 5 min, and washed with clean water. The washed cotton fiber is dried until dry, and the drying temperature is 50°C.

[0037] The long-staple cotton yarn after the anti-ultraviolet treatment of this embodiment was spun and woven, and the ultraviolet protection factor (UPF) of the pure cotton fabric was tested to be 39.1.

Embodiment 2

[0039] According to the above process steps: select 5g of fine-staple cotton as the cotton fiber to be anti-ultraviolet finishing, weigh 0.75g of butyl titanate and mix with 250ml of absolute ethanol, stir evenly to prepare a sol solution with a concentration of 3g / L, and mix 5g of cotton The fibers were immersed in 200ml of the prepared sol solution, and stood at 30°C for 15min. The cotton fiber after soaking is rolled, and the rolling pressure is 0.4MP. The cotton fibers after padding were subjected to steam treatment under steam at 70°C for 7 min, and then washed with water. The cotton fiber after washing is dried to dryness, and the temperature of drying is 60 ℃.

[0040] After the anti-ultraviolet treatment of this embodiment, the fine-staple cotton was spun and woven, and the ultraviolet protection factor (UPF) of the pure cotton fabric was tested to be 43.7.

Embodiment 3

[0042] According to the above process steps: select 5g of long-staple cotton as the cotton fiber to be anti-ultraviolet finishing, weigh 1.5g of butyl titanate and mix with 300ml of absolute ethanol, stir evenly to prepare a sol solution with a concentration of 5g / L, and mix 5g of cotton The fibers were immersed in 250ml of the prepared sol solution, and stood at 40°C for 20min. The soaked cotton fibers are rolled and pressed at a rolling pressure of 0.6MP. The cotton fibers after padding were subjected to steam treatment under steam at 80°C for 10 min, and then washed with clean water. Dry the washed cotton fiber until dry, and the drying temperature is 70°C.

[0043] After the anti-ultraviolet treatment of this embodiment, the long-staple cotton was spun and woven, and the ultraviolet protection factor (UPF) of the pure cotton fabric was tested to be 46.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com