Acrylic mounting structure on the back of the carved aluminum plate

An installation structure, acrylic technology, applied in the direction of building structure, construction, etc., can solve the problems of easy falling off, decreased bond strength, and falling off of acrylic plates, so as to save and reduce material loss and cost, shorten construction period, and reduce manpower cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

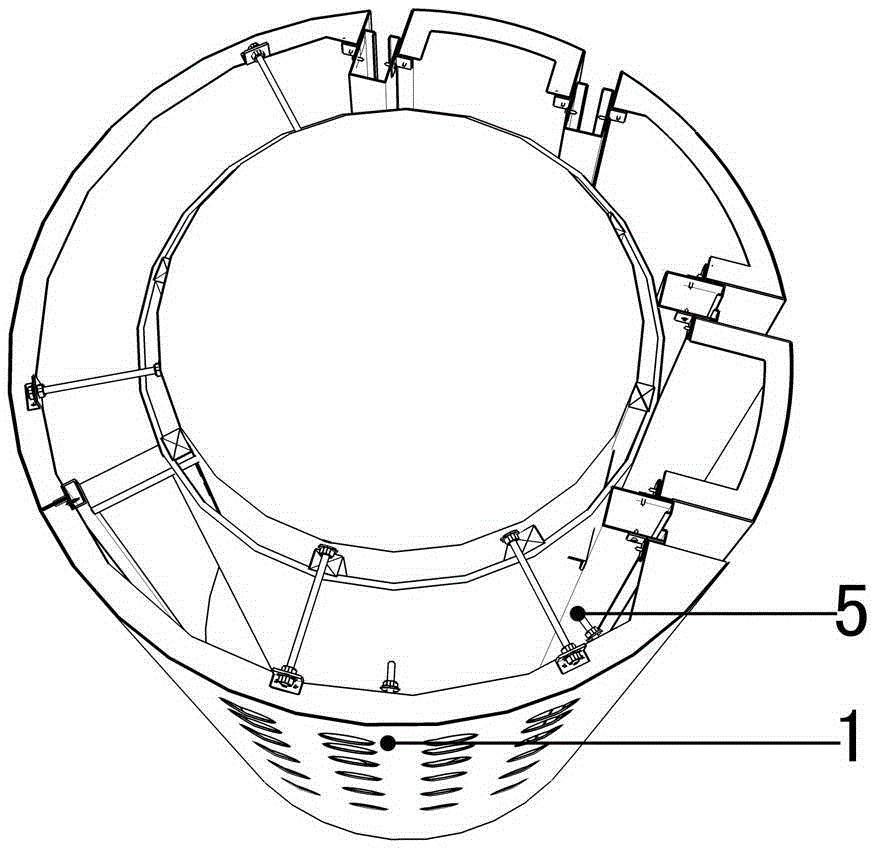

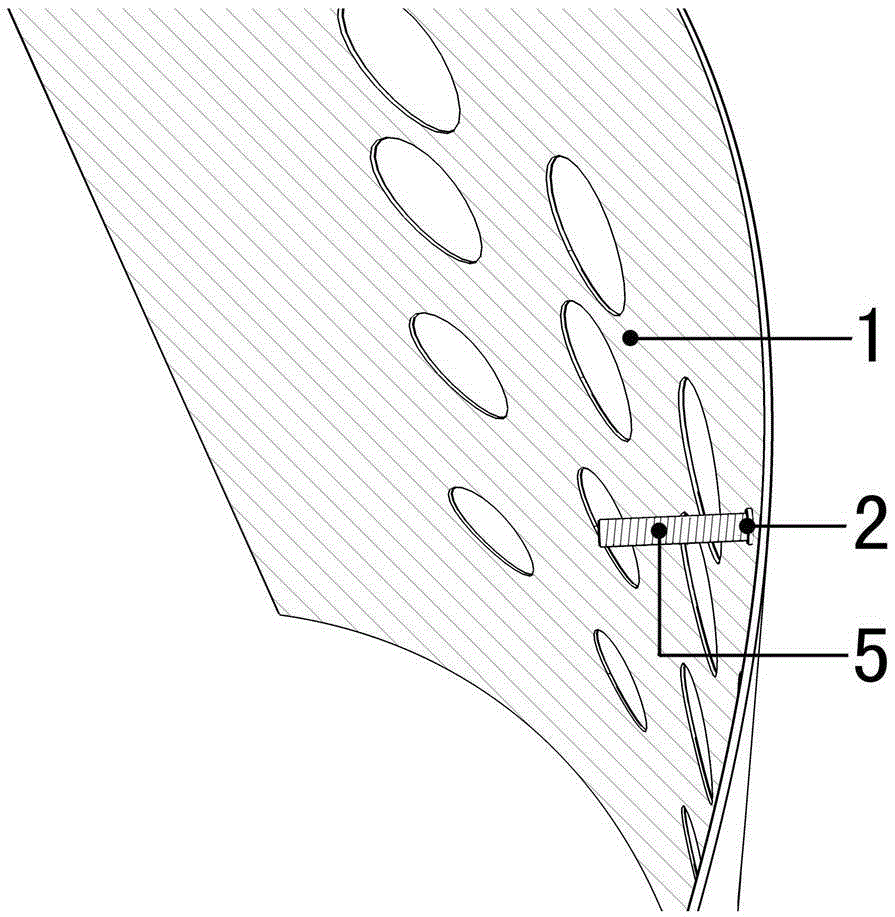

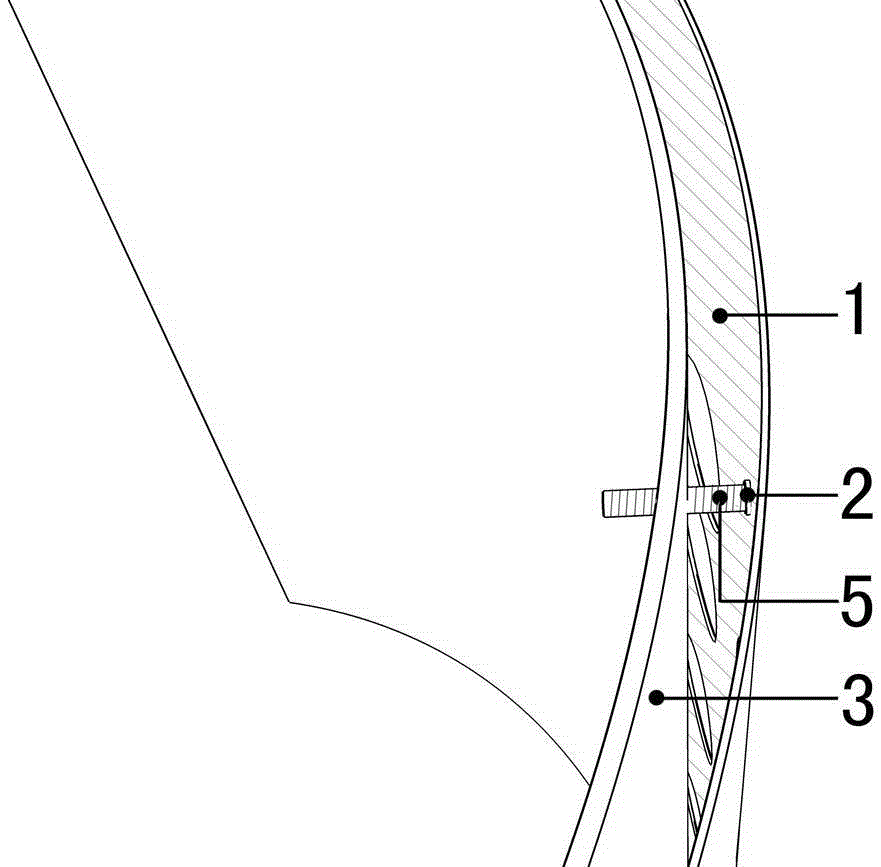

[0015] Example: such as figure 1 As shown, an acrylic mounting structure on the back of a carved aluminum plate includes an aluminum plate 1, an acrylic plate 3, and metal claws 5, and the aluminum plate 1 is a carved aluminum plate. Such as figure 2 , image 3 As shown, the back of the aluminum plate 1 is provided with an acrylic plate 3, and the metal claw 5 is screw-shaped. one end through the hole, such as Figure 4 As shown, the nut 4 is screwed into and installed on the metal claw 5 through the other end of the metal claw 5 and provides the force to press the acrylic plate 3 to the aluminum plate 1. There is also a galvanized plate between the nut 4 and the acrylic plate 3. Gasket 6, so that the acrylic plate 3 and the aluminum plate 1 are fixed together.

[0016] In this embodiment, the aluminum plate 1 adopts welding technology, which can not only increase the firmness of both, but also avoid the release of harmful substances of glass glue in traditional construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com