Centrifugal pump shaft seal water cooling heat dissipation protection system

A water-cooled heat dissipation and protection system technology, applied in the field of centrifugal pumps, can solve the problems of incomplete, untimely cooling, and difficult to reach, and achieve the effects of reasonable structure design, extended service life, and smooth and normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

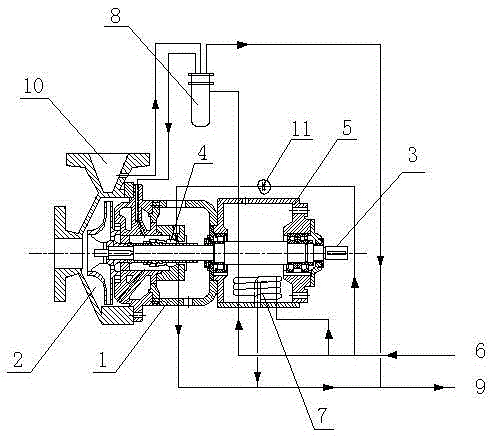

[0011] The centrifugal pump shaft seal water cooling and heat dissipation protection system of the present invention includes a pump casing 1, an impeller casing chamber 2, a pump shaft 3, a shaft seal 4 and a bearing housing 5, and the cooling water line 6 is respectively connected to the inlet of the coil pipe 7 in the bearing housing, The inlet of the outer chamber of the shaft seal 4 and the inlet of the shell side of the heat exchanger 8 are connected; the cooling water return line 9 is respectively connected with the outlet of the coil 7, the outlet of the outer chamber of the shaft seal 4, and the outlet of the shell side of the heat exchanger 8 .

Embodiment 2

[0013] The centrifugal pump shaft seal water cooling and heat dissipation protection system of the present invention includes a pump casing 1, an impeller casing chamber 2, a pump shaft 3, a shaft seal 4 and a bearing housing 5, and the cooling water line 6 is respectively connected to the inlet of the coil pipe 7 in the bearing housing, The inlet of the outer chamber of the shaft seal 4 and the inlet of the shell side of the heat exchanger 8 are connected; the cooling water return line 9 is respectively connected with the outlet of the coil 7, the outlet of the outer chamber of the shaft seal 4, and the outlet of the shell side of the heat exchanger 8 . The outlet of the tube side of the heat exchanger 8 is connected to the inlet of the inner end chamber of the shaft seal 4 in the pump casing 1, and the inner end chamber outlet of the shaft seal 4 passes through the impeller housing chamber 2 to the pump outlet 10 and the tube side of the heat exchanger 8 The entrance is conn...

Embodiment 3

[0015] The centrifugal pump shaft seal water cooling and heat dissipation protection system of the present invention includes a pump casing 1, an impeller casing chamber 2, a pump shaft 3, a shaft seal 4 and a bearing housing 5, and the cooling water line 6 is respectively connected to the inlet of the coil pipe 7 in the bearing housing, The inlet of the outer chamber of the shaft seal 4 and the inlet of the shell side of the heat exchanger 8 are connected; the cooling water return line 9 is respectively connected with the outlet of the coil 7, the outlet of the outer chamber of the shaft seal 4, and the outlet of the shell side of the heat exchanger 8 . The outlet of the tube side of the heat exchanger 8 is connected to the inlet of the inner end chamber of the shaft seal 4 in the pump casing 1, and the inner end chamber outlet of the shaft seal 4 passes through the impeller housing chamber 2 to the pump outlet 10 and the tube side of the heat exchanger 8 The entrance is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com