Elastomer rubber seal ring drag reduction test device and elastomer rubber seal ring/non-smooth surface integrated drag reduction test device

A rubber sealing ring, non-smooth surface technology, applied in the field of drag reduction test devices, can solve the problems of inability to complete the model test, difficulty in daily maintenance, noise pollution, etc., and achieve the effect of convenient daily operation and maintenance, simple and reliable structure, and stable movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

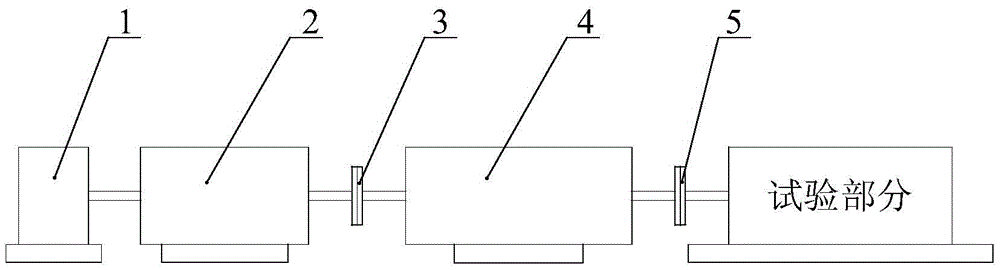

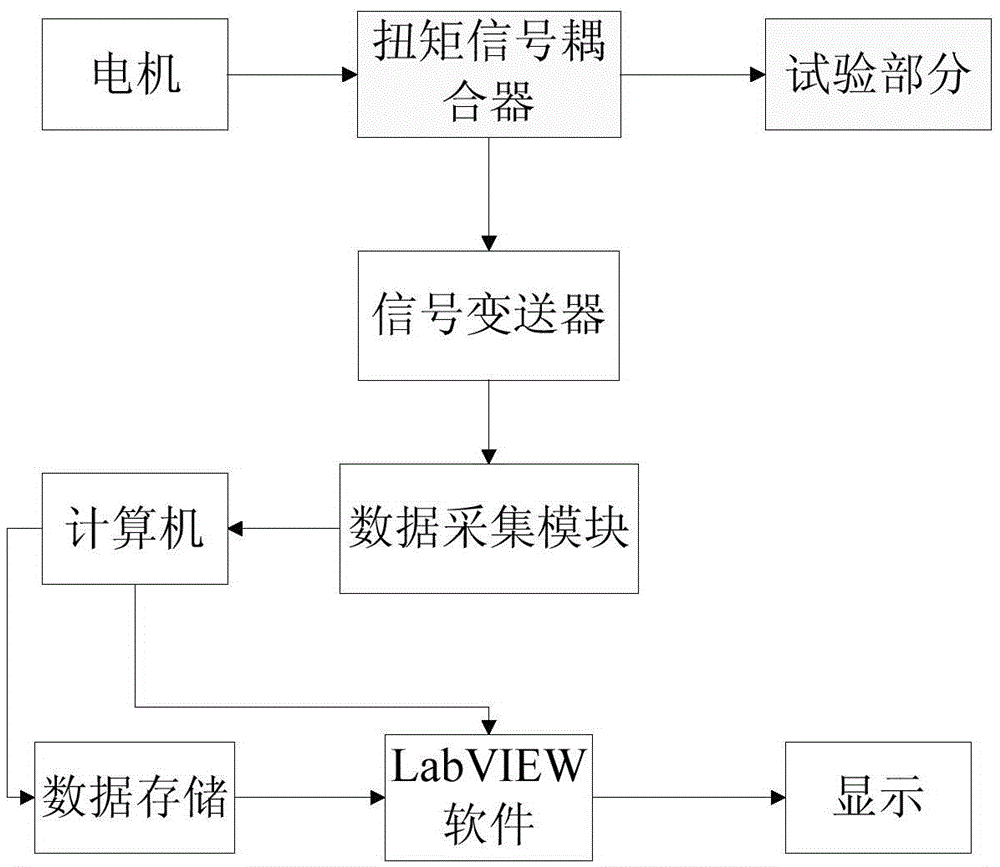

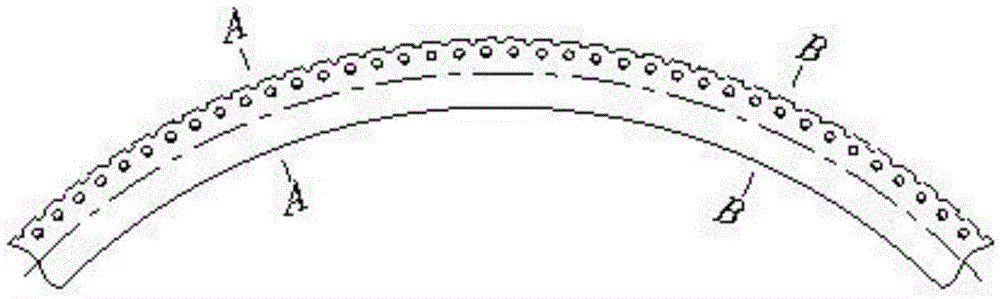

[0025] combine Figure 1-9, the structure of the present invention is mainly divided into three parts: a power part, a data measurement and acquisition part, and a test part, wherein the test part includes two test processes, that is, test process a and test process b. The test process a mainly realizes the friction resistance test of the ○-shaped rubber sealing ring with a non-smooth surface, while the test process b mainly realizes the drag reduction effect test of the test sample with a non-smooth surface. In the test process a, the frequency modulation motor 2 is used as the power source of the whole device, and under the control of the frequency converter 1, it provides rotational power for the whole test device. When the transmission shaft 11 is in a rotating state, it will drive the sample cover cup 18 at its end and the ○-shaped rubber sealing ring 17 fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com