On-line determinator for mine gas explosion triangle and fire risk recognition

A gas explosion and triangular technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of continuous real-time monitoring, analysis data results lagging, large errors, etc., and achieve the effect of real-time analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

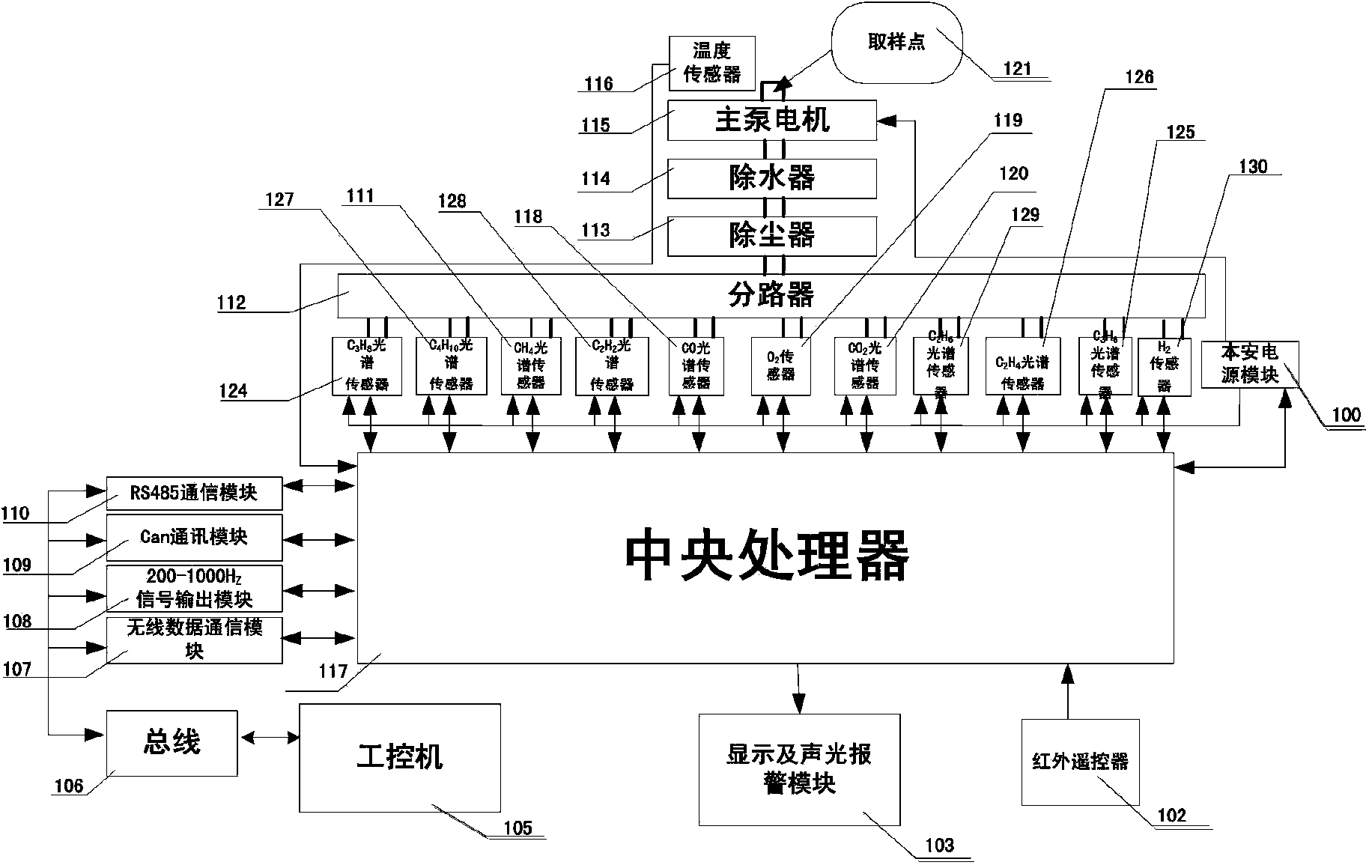

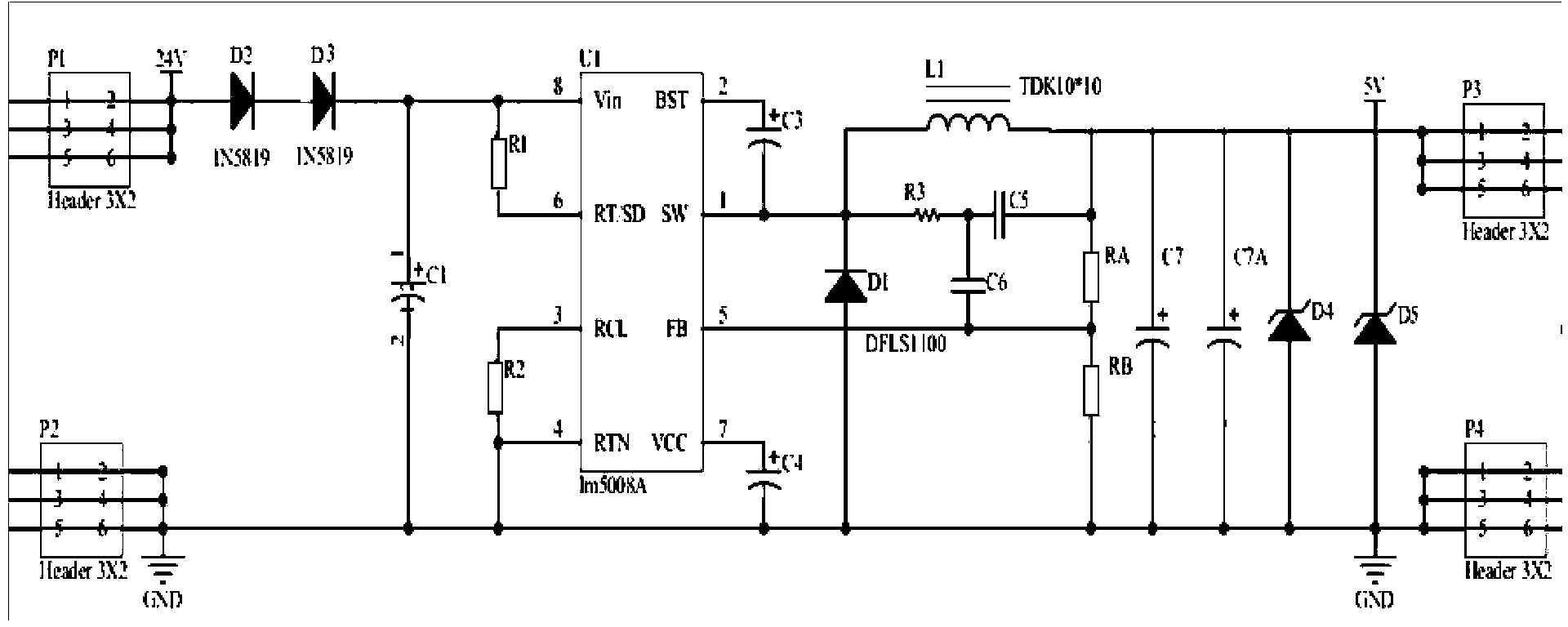

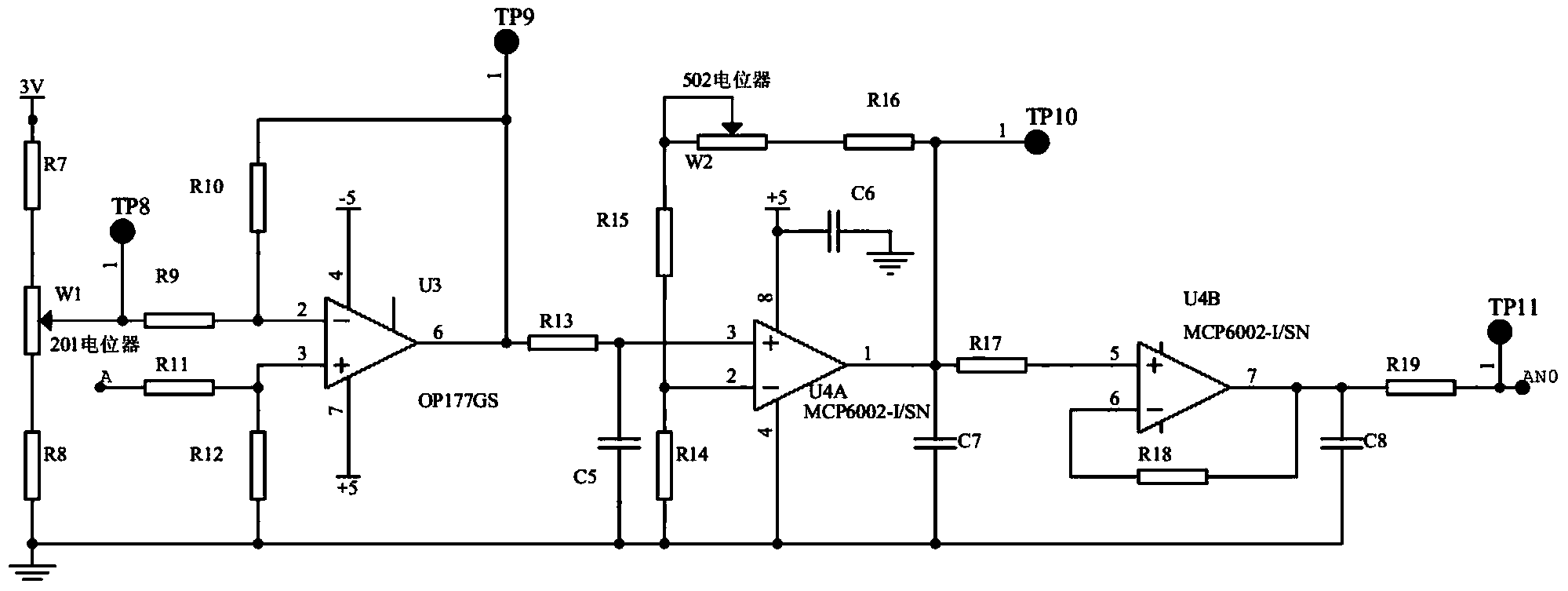

[0029] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 9 , Figure 10 , an online measuring instrument for mine gas explosion triangle and fire hazard identification, comprising a sequence tube at 121 sampling points connected to a main pump motor 115, a water eliminator 114, a dust collector 113, and a splitter 112, characterized in that: the splitter 112 The tubes are respectively connected to various gas sensors in the intrinsically safe housing, the temperature sensor 116 at the sampling point 121 is electrically connected to the central processing unit 117, and the intrinsically safe power module 100 is electrically connected to the main pump motor 115, various gas sensors, and the central processing unit 117 respectively. , the central processing unit 117 is electrically connected to various gas sensors, the display and sound and light alarm module 103 , the infrared remote controller 102 , and each communication mo...

no. 2 example

[0047] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 9 , Figure 10 , an online measuring instrument for mine gas explosion triangle and fire hazard identification, comprising a sequence tube at 121 sampling points connected to a main pump motor 115, a water eliminator 114, a dust collector 113, and a splitter 112, characterized in that: the splitter 112 The tubes are respectively connected to various gas sensors in the intrinsically safe housing, the temperature sensor 116 at the sampling point 121 is electrically connected to the central processing unit 117, and the intrinsically safe power module 100 is electrically connected to the main pump motor 115, various gas sensors, and the central processing unit 117 respectively. , the central processing unit 117 is electrically connected to various gas sensors, the display and sound and light alarm module 103 , the infrared remote controller 102 , and each communication module...

no. 3 example

[0063] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 9 , Figure 10 , an online measuring instrument for mine gas explosion triangle and fire hazard identification, comprising a sequence tube at 121 sampling points connected to a main pump motor 115, a water eliminator 114, a dust collector 113, and a splitter 112, characterized in that: the splitter 112 The tubes are respectively connected to various gas sensors in the intrinsically safe housing, the temperature sensor 116 at the sampling point 121 is electrically connected to the central processing unit 117, and the intrinsically safe power module 100 is electrically connected to the main pump motor 115, various gas sensors, and the central processing unit 117 respectively. , the central processing unit 117 is electrically connected to various gas sensors, the display and sound and light alarm module 103 , the infrared remote controller 102 , and each communication module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com