Method of directly manufacturing antenna on soft magnetic ferrite

A soft ferrite and antenna technology, applied in the direction of antenna coupling, antenna support/installation device, radiating element structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

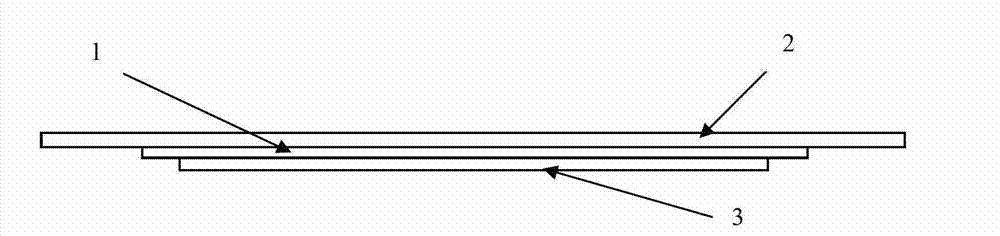

[0035] like figure 1 Shown, a kind of method directly manufacturing antenna on soft ferrite, this method comprises the following steps:

[0036] (1) Paste the protective layer 2, that is, PET film, on the upper surface of the soft ferrite layer 1, and print ink to enhance adhesion on the lower surface according to the antenna pattern, and then dry it at 200°C;

[0037] (2) Then print the conductive ink 3 on the ink that enhances the adhesion, and dry it at 150°C;

[0038] (3) Apply superglue under the conductive ink and attach the peel-off layer.

[0039] During use, the peeling layer is torn off, and the soft ferrite provided with the antenna is pasted on the plastic case of the mobile phone to be installed with the antenna, so that the soft ferrite layer 1 is located between the antenna and the electromagnetic wave generation source.

[0040] The strong printing ink (being Primer printing ink) that adopts in the above-mentioned steps comprises the component of following we...

Embodiment 2

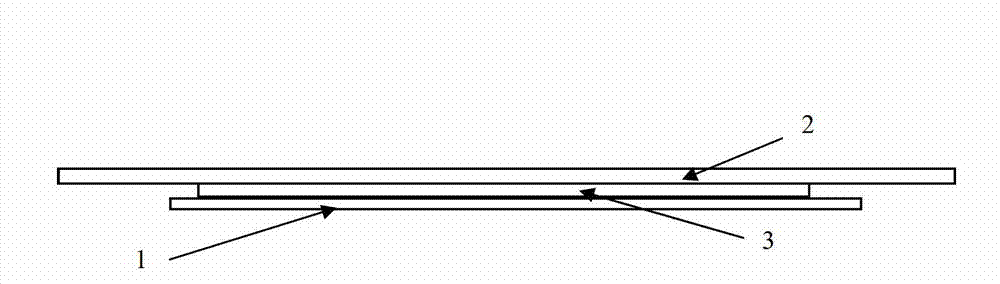

[0042] like figure 2 Shown, a kind of method directly manufacturing antenna on soft ferrite, this method comprises the following steps:

[0043] (1) Printing ink to enhance adhesion on the upper surface of the soft ferrite layer 1 according to the antenna pattern, and then drying at 180° C.;

[0044] (2) Then print the conductive ink 3 on the ink that enhances the adhesion, and dry it at 120° C. to form an antenna;

[0045] (3) Protective layer 2, namely the protective film of PP material, is set above the conductive ink;

[0046] (4) Apply superglue on the lower surface of the soft ferrite layer 1 and attach a peeling layer.

[0047] During use, the peeling layer is torn off, and the soft magnetic ferrite provided with the antenna is pasted on the plastic case of the mobile phone to be installed with the antenna, so that the soft ferrite layer 1 is located between the antenna and the electromagnetic wave generation source.

[0048] The strong printing ink (being Primer prin...

Embodiment 3

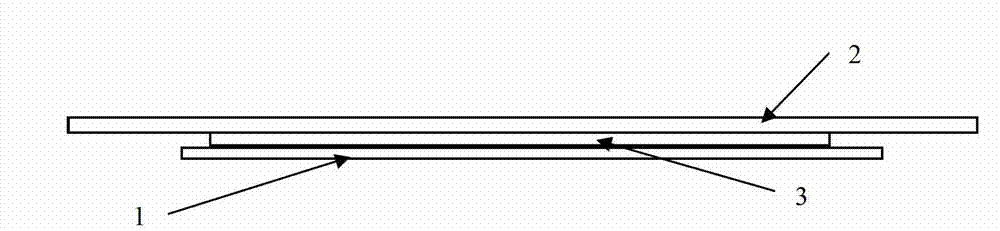

[0050] like image 3 Shown, a kind of method directly manufacturing antenna on soft ferrite, this method comprises the following steps:

[0051] (1) Print the ink to enhance adhesion on the lower surface of the protective layer 2 according to the antenna pattern, and then dry it at 60°C;

[0052] (2) Then print the conductive ink 3 on the ink that enhances the adhesion, and dry it at 60° C. to form an antenna;

[0053] (3) setting a soft ferrite layer 1 under the conductive ink;

[0054] (4) Apply superglue on the lower surface of the soft ferrite layer 1 and attach a peeling layer.

[0055] During use, the peeling layer is torn off, and the soft ferrite provided with the antenna is pasted on the plastic case of the mobile phone to be installed with the antenna, so that the soft ferrite layer 1 is located between the antenna and the electromagnetic wave generation source.

[0056] The strong ink (i.e. Primer ink) of the adhesive strength that adopts in the above steps compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com