Preparation method for graphene carbon crystal polymeric heating plate

An alkene-carbon crystal and polymer technology, applied in the field of heating plate preparation, can solve the problems of waste of energy, difference, poor heating effect, etc., and achieve the effects of reducing resistance, low manufacturing cost and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

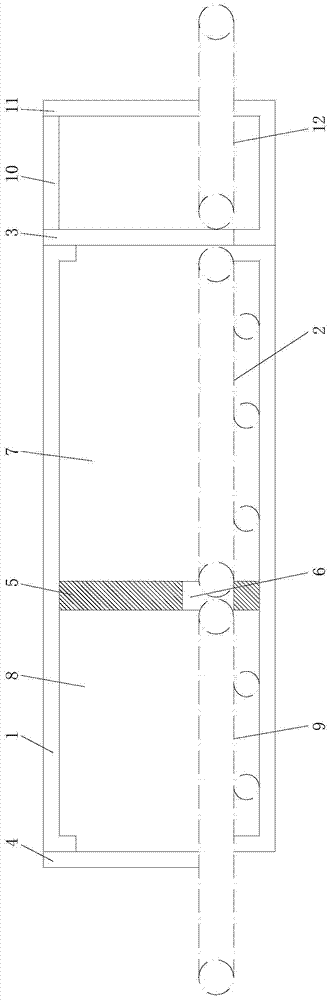

[0034] a) Solder copper strips on both ends of the glass fiber cloth along the width direction of the glass fiber cloth;

[0035]b) Under the conditions of a temperature of 175°C and a pressure of 200t, use a suction hoist to press the copper strip and the glass fiber cloth for 10 minutes;

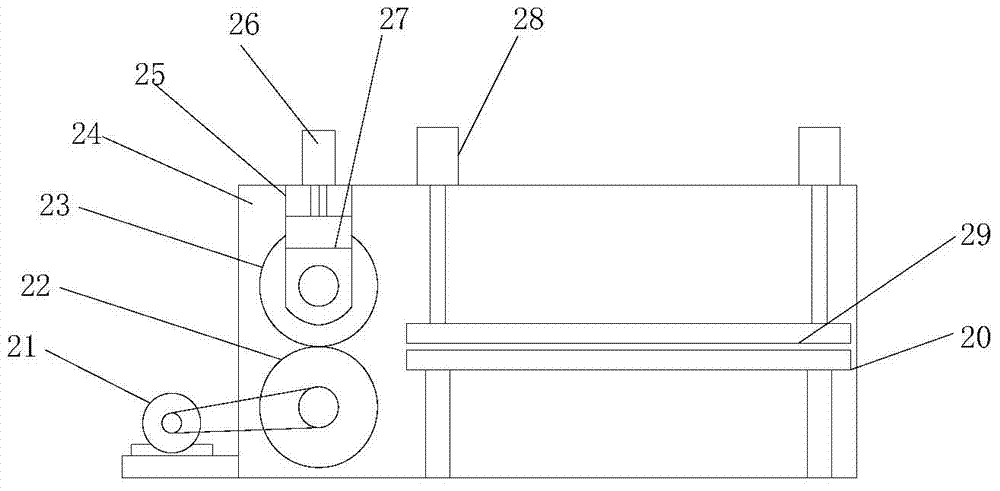

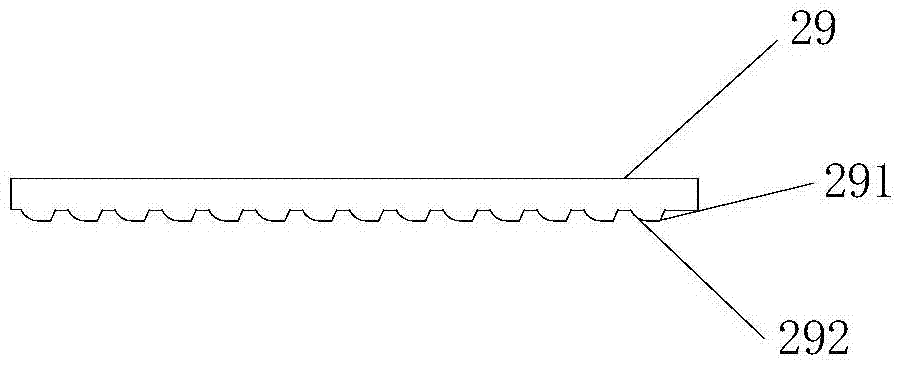

[0036] c) Print the carbon paste onto the front of the glass fiber cloth by a printing machine, design the shape of the carbon paste into a five-pointed star, and put it into the drying tunnel for drying;

[0037] d) Bond two layers of glass fiber insulating layers on the front and back of the glass fiber cloth, and go through the following different stages through the suction hoist (the first stage temperature is 140 ° C, the pressure is 70 t, the second stage temperature is 160 ° C, the pressure is 80 t, the second stage is The temperature in the third stage is 175°C, the pressure is 120t, the temperature in the fourth stage is 180°C, the pressure is 160t, the temperature in the fifth st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com