Method and equipment for circularly drying tea leaves

A technology for circulating drying and tea leaves, which is applied to progressive dryers, drying solid materials, lighting and heating equipment, etc., can solve the problems of complicated setting of drying boxes, complicated installation and maintenance of drying operations, etc., and achieves simple, practical and suitable equipment. The effect of promoting use and low probability of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

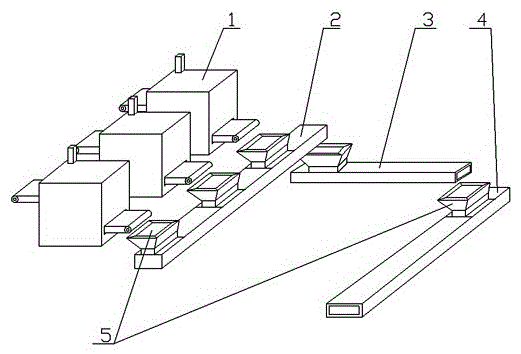

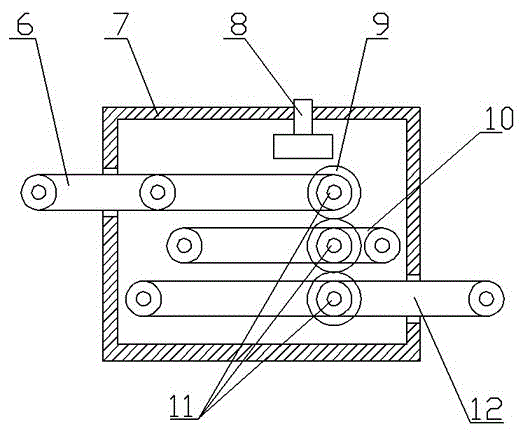

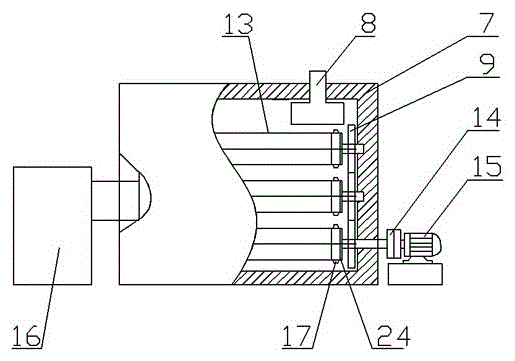

[0032] In order to introduce the present invention in more detail, the present invention will be further described with reference to the accompanying drawings.

[0033] A method for drying tea leaves, which is characterized by comprising the following steps:

[0034] 1) Heating and drying, drying the tea at high temperature to remove more water in the tea, and to a certain extent achieve a preliminary sterilization effect on the tea, the drying temperature is 100~150℃, and the drying time is 5~15 minutes, under this condition, can make the moisture in the tea ≤30%;

[0035] 2) Primary cooling. The tea obtained from the first high-temperature drying process is continuously heated and dried at medium and high temperatures, so that there will be no quality changes due to excessive temperature differences, and the remaining part of the moisture in the tea will be further dried. The duration of this process is 10-15 minutes, and the temperature is 60-80℃; it can make the moisture in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com