Manufacturing method for multi-metal saw blade

A manufacturing method and multi-metal technology, applied in the manufacture of cutting tools of sawing machines, metal sawing equipment, manufacturing tools, etc., can solve the problems of reducing the service life of saw blades, prone to continuous chipping, and the scrapping of the entire band saw, etc., to achieve Increased service life, long service life, and the effect of preventing scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

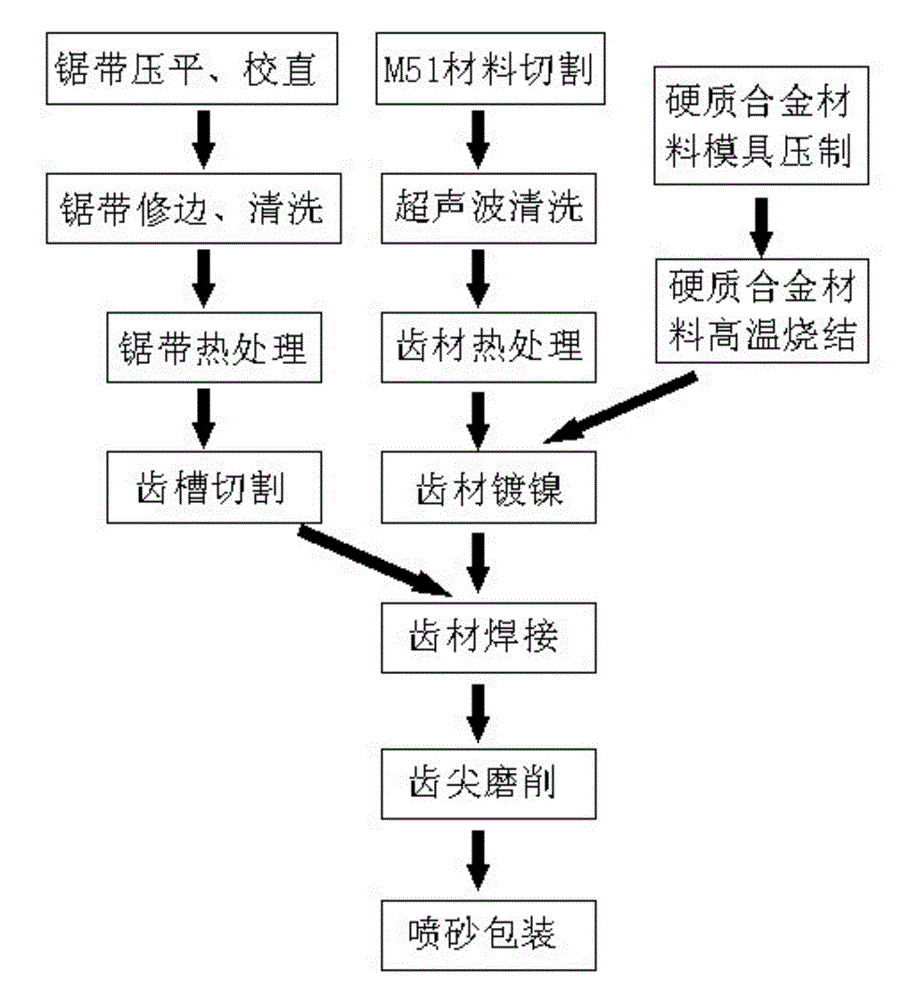

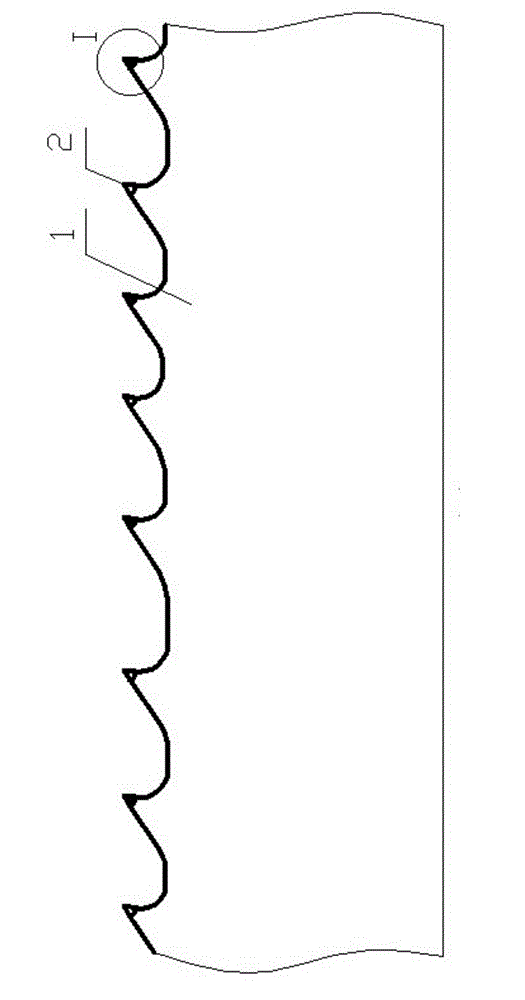

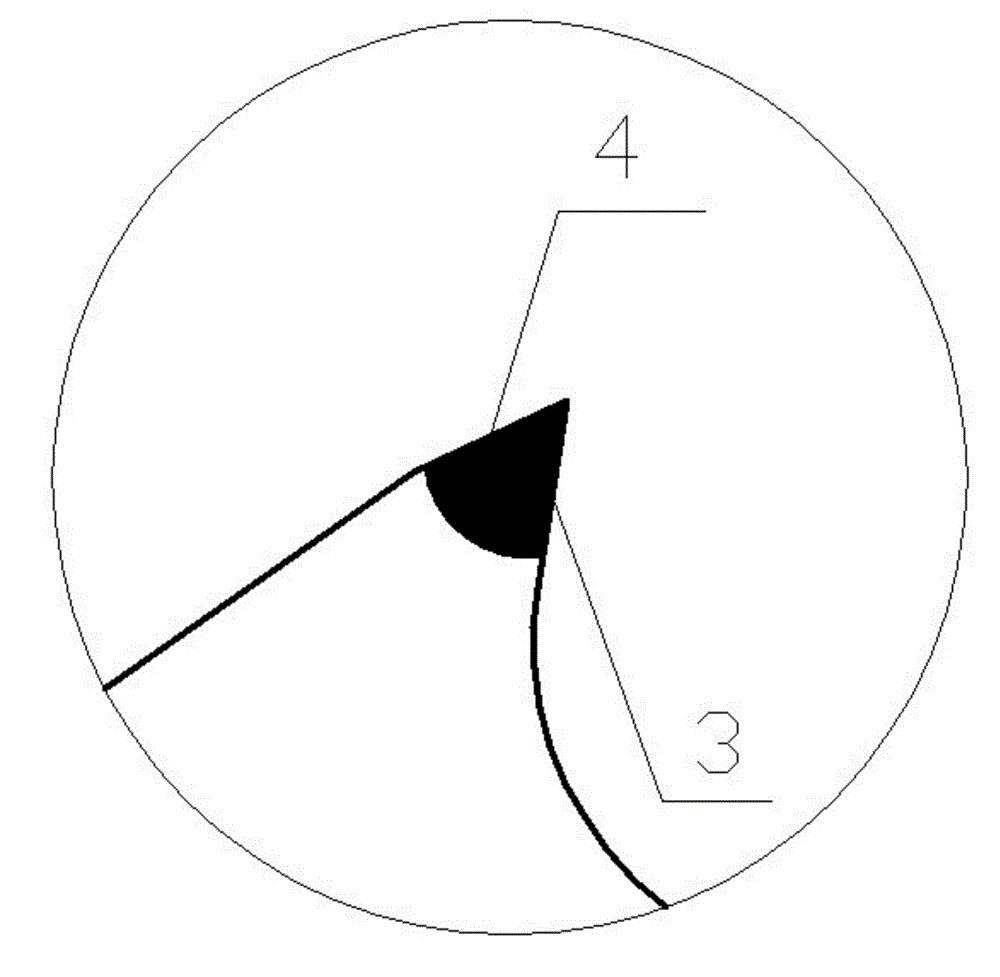

[0033] A method of manufacturing a multi-metal saw blade, such as Figure 1 to Figure 4 shown, including the following steps,

[0034] Step 1: The tooth material 2 is M51 material and cemented carbide material, and the M51 material is subjected to heat treatment, and the cemented carbide material is subjected to high-temperature sintering treatment; the specific operation is as follows:

[0035] Before heat treatment, the M51 material is cut into a cylinder with a diameter of 2.0-3.0mm and a thickness of 1.6-2.0mm, and then the oil stain on the surface is cleaned by ultrasonic waves, and then heat treatment is performed; the heat treatment is to put the M51 material after cleaning the oil stain into the temperature Quenching is carried out in a vacuum furnace at 1185-1200°C. After 15 minutes, it can also be any value between 10 minutes or 30 minutes or 10-30 minutes. It is immersed in liquid nitrogen at a temperature of -230--190°C for cryogenic treatment. , The cryogenic tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com