Method for regulating morphology and structure of nanometer silicon

A nano-silicon and morphology technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of complex conditions for controlling morphology, environmental pollution, etc., and achieve high purity, simple process flow, reaction equipment and reaction. Effects with low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

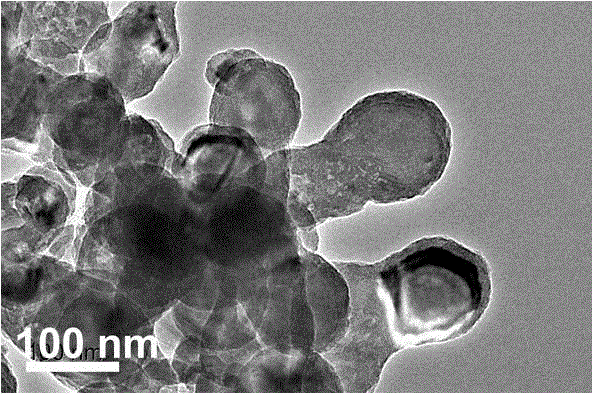

[0017] Add 80 mg of silicon particles with a particle size of 100 nm into a mixed solution of 20 ml of water and 120 ml of ethanol, and ultrasonically disperse for 20 min. Add 2 ml of 30% ammonia water to the above solution, and stir at constant temperature for 10 min. The stirred product was immediately centrifuged, washed with a large amount of ethanol until neutral, and then dried in a vacuum oven.

[0018] as attached figure 1 As shown by transmission electron microscopy (TEM), the obtained silicon / silica material has a core-shell structure.

Embodiment 2

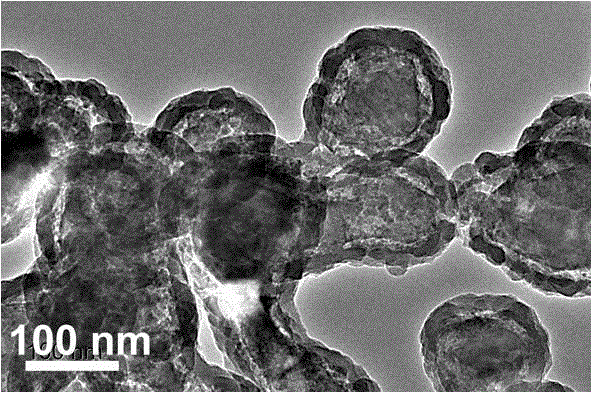

[0020] Add 80 mg of silicon particles with a particle size of 100 nm into a mixed solution of 20 ml of water and 120 ml of ethanol, and ultrasonically disperse for 20 min. Add 2ml of 30% ammonia water to the above solution, and stir at constant temperature for 1h. The stirred product was immediately centrifuged, washed with a large amount of ethanol until neutral, and then dried in a vacuum oven.

[0021] as attached figure 2 As shown by transmission electron microscopy (TEM), the obtained silicon / silica material has an egg yolk eggshell structure.

Embodiment 3

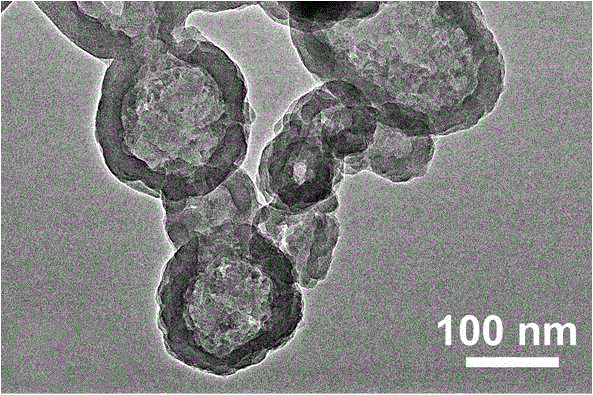

[0023] Add 80 mg of silicon particles with a particle size of 100 nm into a mixed solution of 20 ml of water and 120 ml of ethanol, and ultrasonically disperse for 20 min. Add 2ml of 30% ammonia water to the above solution, and stir at constant temperature for 24h. The stirred product was immediately centrifuged, washed with a large amount of ethanol until neutral, and then dried in a vacuum oven.

[0024] as attached image 3 As shown by transmission electron microscopy (TEM), the obtained silica material has a hollow structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com