Micro-displacement Optical Lever Laser Measurement System and Its Magnetomechanical Oxygen Sensor

A technology of laser measurement system and optical lever, which is applied in the laser measurement system and its application field, can solve the problems of affecting the measurement effect, poor mechanical strength, large beam divergence, etc., so as to avoid the process of adjusting the optical focus, save the cost of use, and ensure the accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

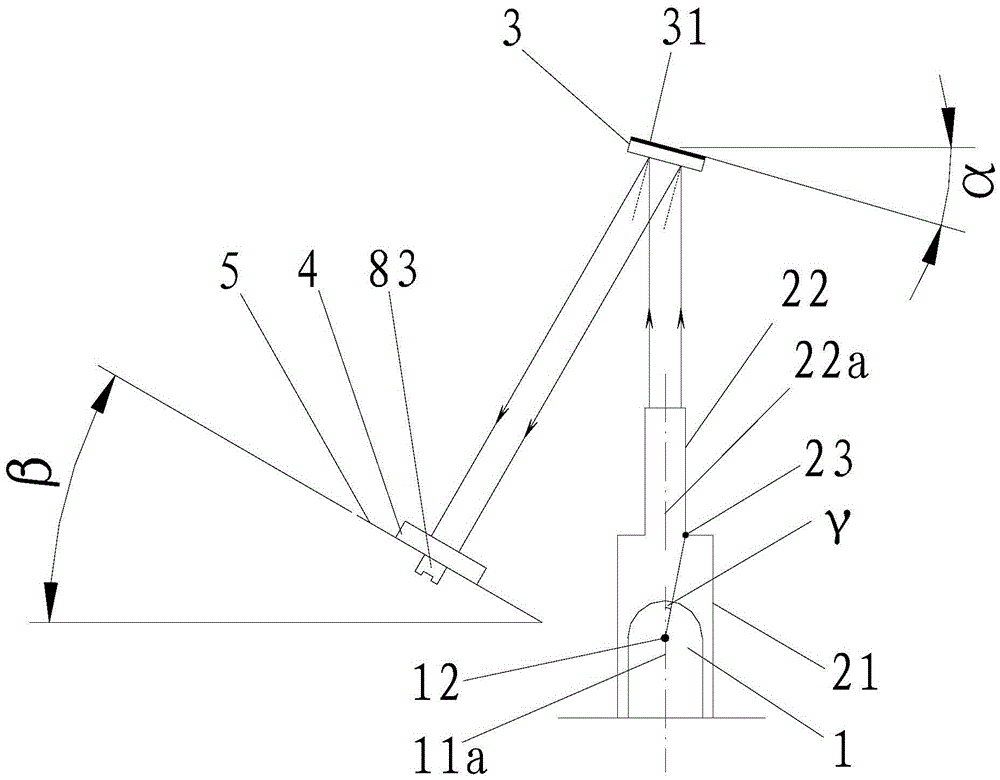

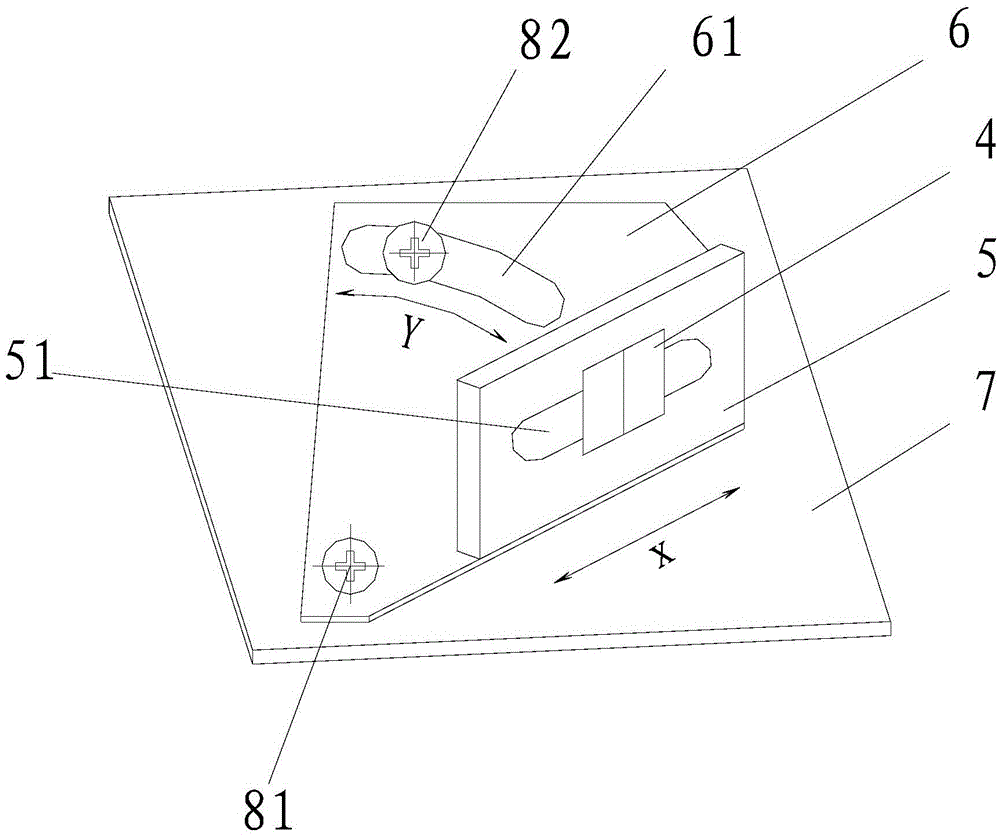

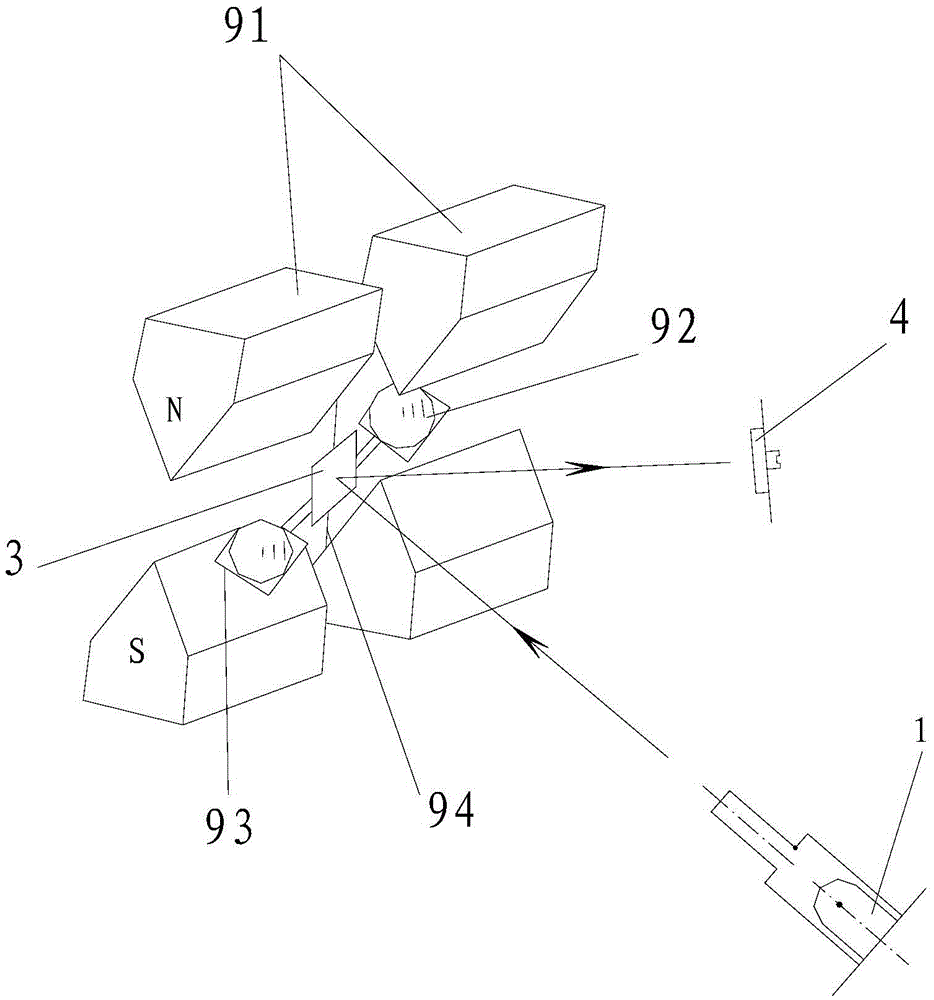

[0021] figure 1 It is a structural schematic diagram of the micro-displacement optical lever laser measurement system of the present invention, figure 2 It is a structural schematic diagram of the photoelectric detector and the mounting assembly of the present invention, image 3 It is a schematic structural diagram of the magnetomechanical oxygen sensor of the present invention, as shown in the figure: the micro-displacement optical lever laser measurement system of this embodiment includes: a laser generator for emitting laser beams; a beam collimator for collimating Straighten the laser beam emitted by the laser generator; the plane mirror 3 is used to reflect the laser beam collimated by the beam collimator; and the photodetector 4 is used to receive the laser beam reflected by the plane mirror 3 Beam and output electrical signal; wherein, the laser generator includes a laser diode 1, the beam collimator includes a bottom tube 21 for covering the transparent package of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com