Parallel low-light-loss high-temperature backlight industrial endoscope

A parallel low light loss, high temperature industrial technology, applied in the field of endoscopy, can solve the problem of difficult image and video information collection, and achieve the effects of improved backlight light efficiency, convenient modular replacement, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

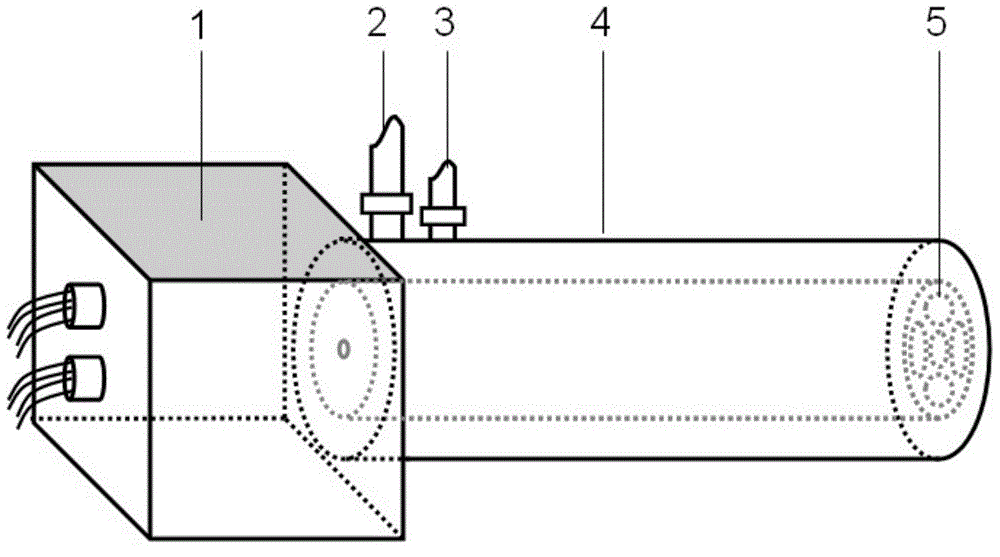

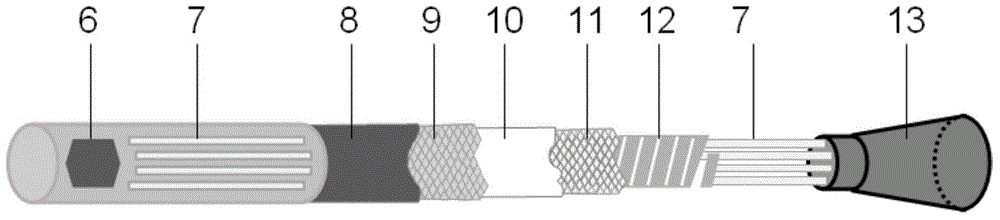

[0050] see figure 1 . Parallel low-light-loss backlight high-temperature industrial endoscope, including an optical eyepiece 13 for taking images in a furnace, a light source light-emitting component 14, a light source driving circuit, a communication circuit, an image guiding fiber bundle 7, a light guiding structure, an imaging driving circuit and a housing The shell is made of 306 steel, including two parts: a round tube 4 and a square shell 1. The square shell is connected to the tail of the cylinder; the length of the round tube is 2 meters.

[0051] A light source driving circuit, an imaging driving circuit for driving the imaging chip 6 and a communication circuit are arranged in the square housing 1 .

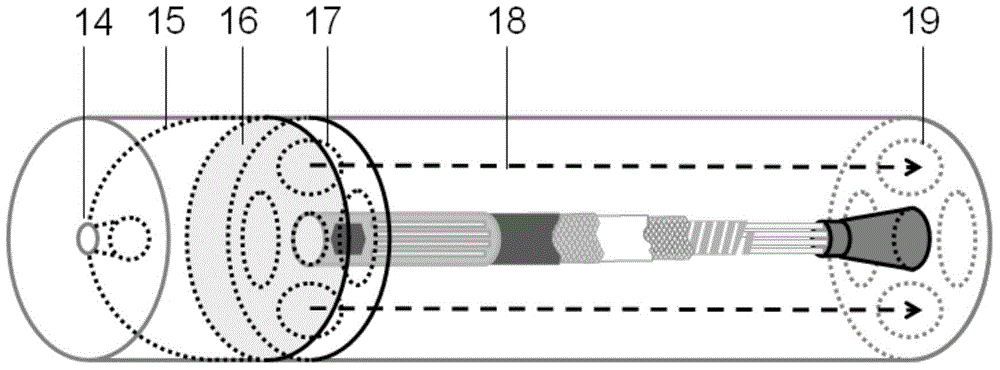

[0052] The tail of the circular tube is provided with a light guide structure, a light source light-emitting part 14, and an imaging chip 6; the light guide structure includes an ellipsoidal concave mirror 15 arranged at the rear of the light source light-emitting part...

Embodiment 2

[0070] The structure of endoscope is the same as embodiment 1.

[0071] The industrial endoscope in this embodiment can be applied to image acquisition of non-high temperature industrial equipment, including steps:

[0072] 1) Install the parallel low-light-loss backlight high-temperature industrial endoscope on the outer wall of the industrial equipment, the front end of the round tube 4 is set inside the equipment, and the square casing 1 is located outside the equipment;

[0073] 2) Start the light source driving circuit to start working, the light source light-emitting part 14 emits light; the light generated by the light source light-emitting part passes through the parallel light generator composed of the ellipsoidal concave mirror 15 and the circular convex lens 16 to form parallel light, and hits the porous light barrier 17 ; the parallel light forms a plurality of light guiding light paths 18 under the action of the porous light shielding plate 17 , and the light pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com