Temperature control system of vertical type drying tower

A vertical drying tower and temperature control system technology, applied in control/regulation system, drying, drying machine, etc., can solve the problems of increased power loss, easy damage of thermal resistance, large power consumption of power regulator, etc., to achieve Reduce power consumption, reduce production costs, and improve the effect of operating cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

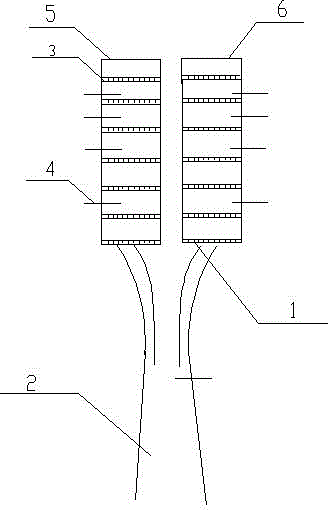

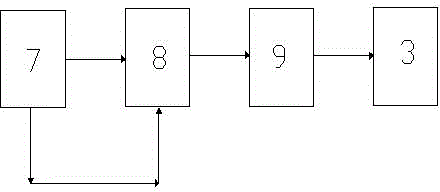

[0020] Such as figure 1 with figure 2 As shown, the temperature control system of a vertical drying tower in this embodiment includes a drying tower body 1, a ventilation pipeline 2, a heating element 3 and a temperature controller 4, and the ventilation pipeline 2 is connected to the drying tower body 1, the drying tower body 1 has seven layers, several heating elements 3 are arranged in the drying tower body 1, the temperature controller 4 is electrically connected to the heating element 3, and the temperature control There are five devices 4, which are respectively set on the second layer, the fourth layer, the fifth layer, the sixth layer and the ventilation pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com