Chitosan/lithium chloride composite membrane, preparation method and applications thereof

A chitosan, lithium chloride technology, applied in chemical instruments and methods, separation methods, membrane technology and other directions, can solve problems such as limitations, and achieve the effects of convenient operation, high separation performance, and improved dehumidification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

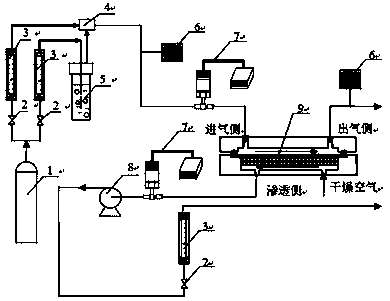

Image

Examples

Embodiment 1

[0028] (1) Use an electronic balance to accurately weigh 2g of chitosan with a degree of deacetylation of not less than 90%, add it to a 1% (v / v) acetic acid aqueous solution, and prepare a chitosan film casting solution with a total mass of 100g. Use a magnetic stirrer for uniform stirring at room temperature to obtain a completely dissolved chitosan solution.

[0029] (2) Use a Buchner funnel with two layers of filter paper to suction filter the completely dissolved chitosan casting film solution, and remove the tiny insoluble matter still remaining in the solution through filtration;

[0030] (3) Use the combined method of standing and vacuuming to remove bubbles from the chitosan casting film solution after removing impurities, and finally ensure that the chitosan casting film solution is bubble-free under a negative atmospheric pressure;

[0031] (4) Casting the chitosan film solution prepared by the above steps into a film-casting plate solution into a uniform thickness and dry...

Embodiment 2

[0047] (1) Use an electronic balance to accurately weigh 2g of chitosan with a degree of deacetylation not less than 90% and a certain mass of lithium chloride (the mass ratio of chitosan to lithium chloride is 20:1), and add to 1% ( v / v) acetic acid aqueous solution, prepare a total mass of 100g chitosan / lithium chloride mixed casting film solution, use a magnetic stirrer at room temperature for uniform stirring, to obtain completely dissolved chitosan / lithium chloride Cast film solution.

[0048] (2) Use a Buchner funnel with two layers of filter paper to suction filter the completely dissolved chitosan / lithium chloride casting film solution, and remove the tiny insoluble matter still remaining in the solution by filtration;

[0049] (3) Use the combined method of standing and vacuuming to remove bubbles from the chitosan / lithium chloride casting film solution after removing impurities, and finally ensure that the solution is bubble-free under a negative atmospheric pressure;

[0...

Embodiment 3

[0066] (1) Use an electronic balance to accurately weigh 2g of chitosan with a degree of deacetylation of not less than 90% and 0.2g of lithium chloride (the mass ratio of chitosan to lithium chloride is 10:1), and add to 1% (v / v) acetic acid aqueous solution, prepare a total mass of 100g chitosan / lithium chloride mixed casting film solution, use a magnetic stirrer at room temperature for uniform stirring, to obtain a completely dissolved chitosan / lithium chloride casting Membrane solution.

[0067] (2) Use a Buchner funnel with two layers of filter paper to suction filter the completely dissolved chitosan / lithium chloride casting film solution, and remove the tiny insoluble matter still remaining in the solution by filtration;

[0068] (3) Use a combined method of standing and vacuuming to remove bubbles from the chitosan / lithium chloride casting film solution after removing impurities, and finally ensure that the solution is bubble-free under a negative atmospheric pressure;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com