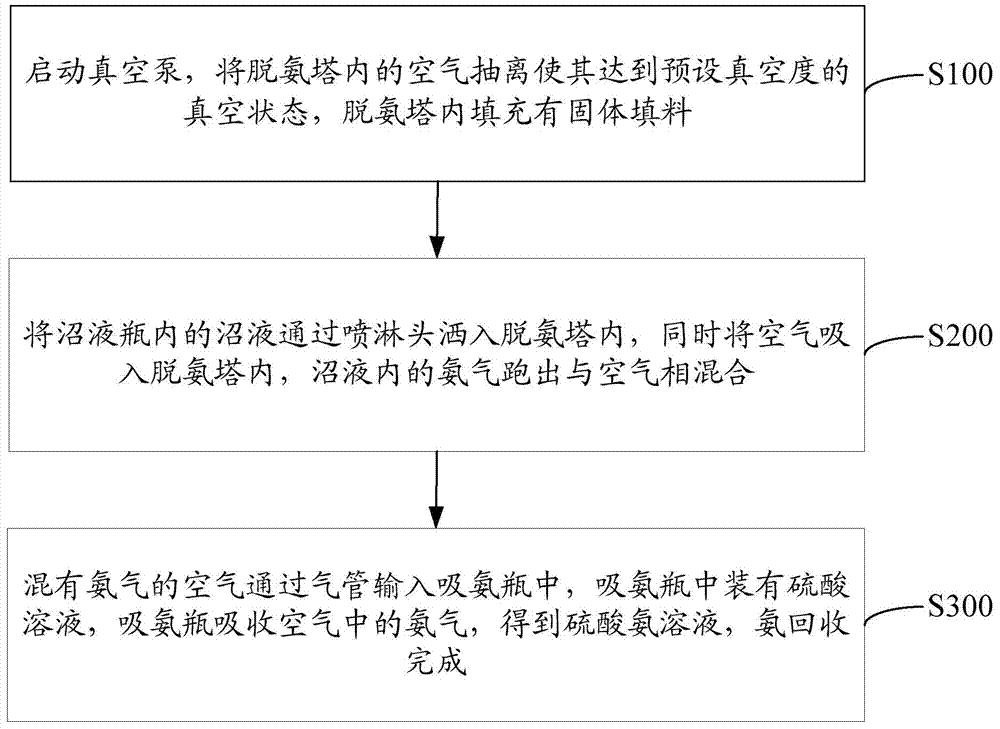

Biogas slurry deamination and ammonia recovery method

An ammonia recovery and biogas slurry technology, which is applied in the fields of biogas slurry deamination and ammonia recovery, can solve the problems of excess consumption load, large amount of biogas slurry, low utilization efficiency of compound nutrient fertilizer, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

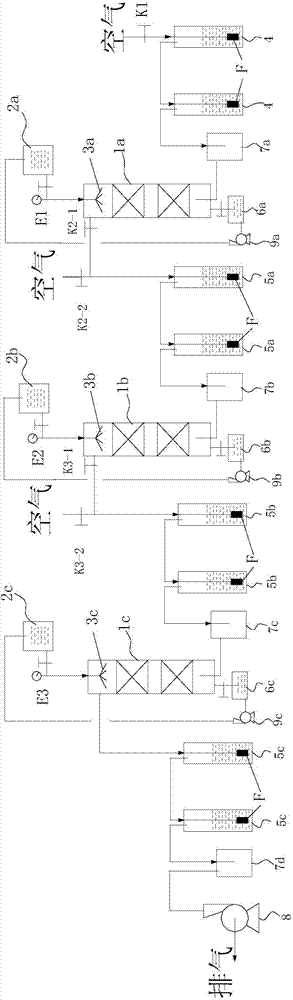

[0035] Example 1: Take 3000 ml of biogas slurry, add lime to adjust its pH value to 9.5, let it stand for 2 hours, take 1500 ml of supernatant, add 500 ml to each of biogas slurry bottles 2a, 2b, and 2c, and put them in each ammonia suction bottle Add 10% dilute sulfuric acid to 5a, 5b, and 5c, add saturated lime water to the lye absorption bottle 4, close the valves K1, K2-2, and K3-2, turn on the vacuum pump 8, vacuumize, and adjust the vacuum degree E1 to be equal to 0.05 MPa, then adjust the opening of the outlet valves of the biogas slurry bottles 2a, 2b, and 2c so that the biogas slurry in each biogas slurry bottle 2a, 2b, and 2c is exhausted within 1 hour. The ammonia nitrogen content of the biogas slurry was analyzed, and compared with the content of the biogas slurry in the biogas slurry bottles 2a, 2b, and 2c, the removal rate of ammonia nitrogen was obtained:

[0036] The deamination rate of 1a deamination tower---76.5%, the deamination rate of 1b deamination tower-...

Embodiment 2

[0037] Embodiment 2, take 3000 ml of biogas slurry, add lime to adjust its pH value to 12.2, leave it for 2 hours, take 1500 ml of supernatant, add 500 ml to each of biogas slurry bottles 2a, 2b, and 2c, and put them in each ammonia suction bottle Add 10% dilute sulfuric acid to 5a, 5b, and 5c, add saturated lime water to the lye absorption bottle 4, close the valves K1, K2-2, and K3-2, turn on the vacuum pump 8, vacuumize, and adjust the vacuum degree E1 to be equal to 0.07 MPa, then adjust the opening of the outlet valves of the biogas slurry bottles 2a, 2b, and 2c so that the biogas slurry in each biogas slurry bottle 2a, 2b, and 2c is exhausted within 1 hour. The ammonia nitrogen content of the biogas slurry was analyzed, and compared with the content of the biogas slurry in the biogas slurry bottles 2a, 2b, and 2c, the removal rate of ammonia nitrogen was obtained:

[0038] 1a deamination tower deamination rate---84.2%, 1b deamination tower deamination rate---73.7%, 1c de...

Embodiment 3

[0039]Example 3: Take 3000 ml of biogas slurry, add lime to adjust its pH value to 10.5, leave it for 2 hours, take 1500 ml of supernatant, add 500 ml to each of the biogas slurry bottles 2a, 2b, and 2c, and put them in each ammonia suction bottle Add 10% dilute sulfuric acid to 5a, 5b, and 5c, add 10% sodium hydroxide solution to the lye absorption bottle 4, close the valves K1, K2-2, and K3-2, turn on the vacuum pump 8, vacuumize, and adjust the vacuum E1 is equal to 0.055MPa, and then adjust the opening of the outlet valves of the biogas slurry bottles 2a, 2b, and 2c so that the biogas slurry in each biogas slurry bottle 2a, 2b, and 2c is pumped out within 1 hour. , 6c, the biogas slurry was taken to analyze the ammonia nitrogen content, and compared with the biogas slurry content in the biogas slurry bottles 2a, 2b, and 2c, the removal rate of ammonia nitrogen was obtained:

[0040] 1a deamination tower deamination rate---75%, 1b deamination tower deamination rate---72.6%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com