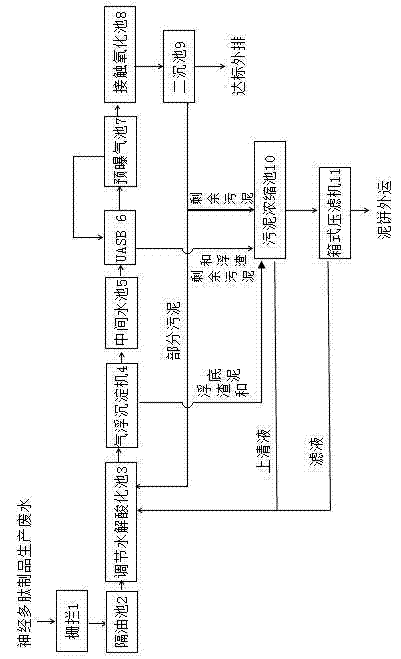

Treatment process for waste water in neuropeptide product production

A technology for the production of wastewater and neuropeptides, which is applied in degassed water/sewage treatment, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of environmental pollution, wastewater is difficult to separate for treatment, etc., to achieve High methane production activity, easy operation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A treatment process for wastewater produced by neuropeptide products, comprising the following steps:

[0030] (1) The waste water from the production of neuropeptide products is intercepted by the grille 1 to intercept larger floating objects and impurities in the sewage, and then enters the grease trap 2 to remove the slick oil, and the slick oil removed by the grease trap 2 is manually cleaned After the oil is separated, the sewage flows into the regulating hydrolysis and acidification tank 3, and the sewage is hydrolyzed and acidified by stirring the activated sludge;

[0031] (2) Adjusting the acidified sewage in the hydrolysis acidification tank 3 enters the air flotation sedimentation machine 4, and through the action of the compound flocculant PAM and coagulant aid PAC, the polluted suspended matter in the wastewater undergoes coagulation and flocculation reaction; the air flotation sedimentation machine 4 produces The flocs and the fine air bubbles released in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com