Concrete-filled square steel tubular column with built-in spiral stirrup

A technology of spiral stirrups and concrete columns, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of uneven core concrete restraint, local buckling of pipe walls, and increased welding difficulty, so as to improve the poor restraint effect And non-uniform, good constraint performance, template-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

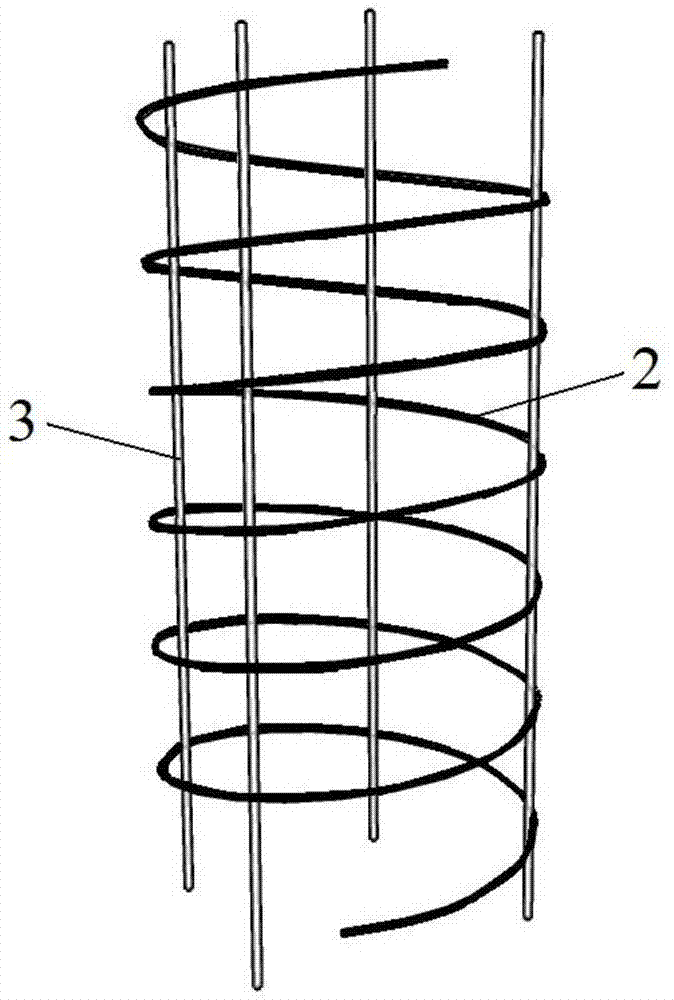

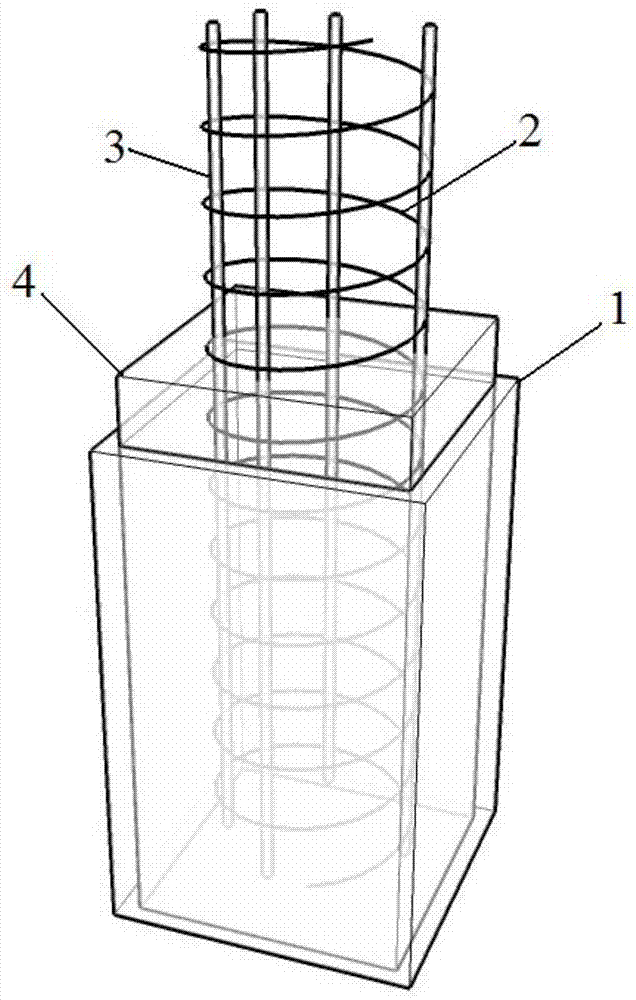

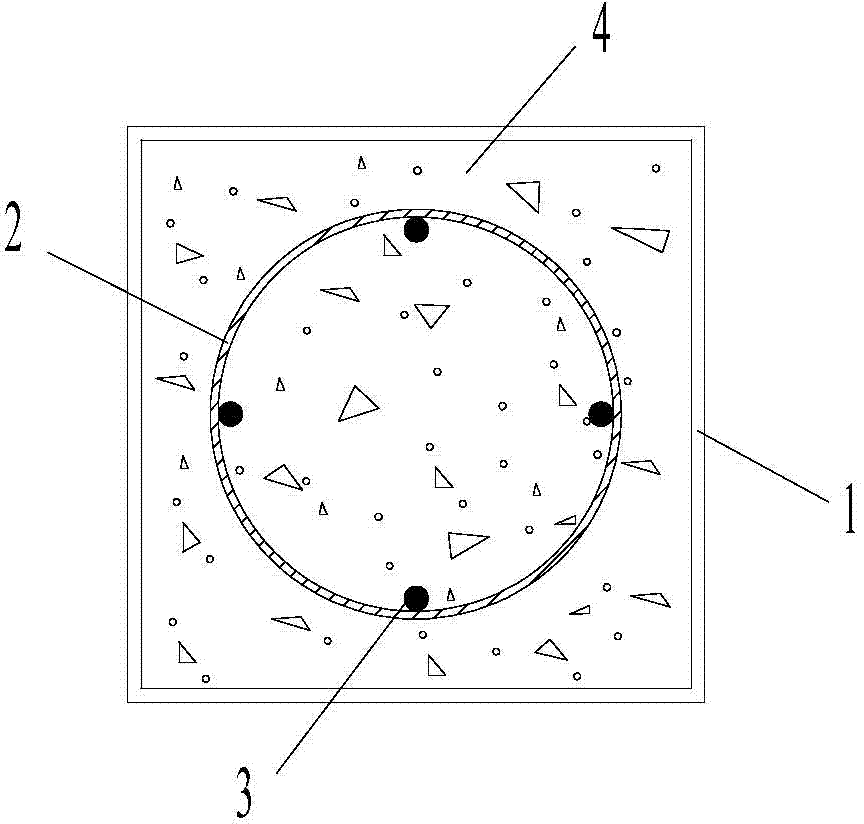

[0023] Specific implementation method: the square steel pipe concrete column with built-in spiral stirrup in this embodiment is composed of square steel pipe 1, spiral stirrup 2, longitudinal reinforcement 3 and core concrete 4, and longitudinal reinforcement 3 is arranged on the inner wall of spiral stirrup 2 to form a spiral reinforcement cage. Place the spiral steel cage at the center of the square steel pipe 1, the central axis of the spiral steel cage coincides with the central axis of the square steel pipe 1, fill the inner space of the square steel pipe 1 with the core concrete 4, and form a square steel pipe concrete column with built-in spiral stirrups.

[0024] The spiral steel bar 2 described in this embodiment and the height of the longitudinal steel bar 3 are equal to the square steel pipe 1, the longitudinal steel bar 3 is bound or welded on the inner wall of the spiral stirrup 2, and the minimum distance from the inner wall surface of the square steel pipe 1 to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com