Deposited-carbon cleaning device of automobile

A cleaner and carbon deposition technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of inconvenient use, expensive cleaning costs, uneconomical, etc., and achieve the effects of cost reduction, light weight, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

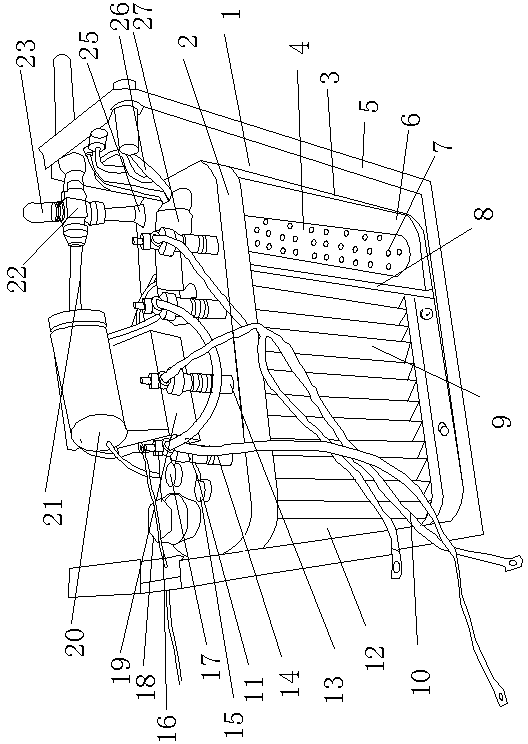

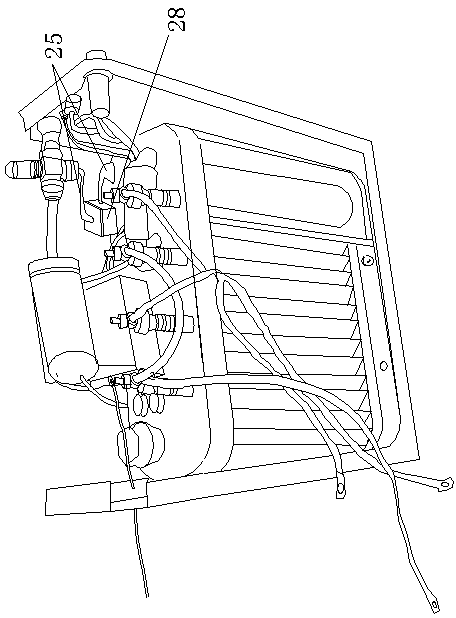

[0026] Example 1, such as figure 1As shown, a car carbon deposit cleaner includes a frame body 5, a gas generating device, and a pressurizing device. The gas generating device includes at least one carbon deposit cleaner body 1, and the carbon deposit cleaner body 1 includes a box body 3 and the box cover 2 fastened on the top of the box body 3; a partition 8 is erected in the box body 3, and the box body 3 is divided into an electrolytic chamber 12 and a filter chamber 6 which are independent of each other through the partition board 8, The electrolysis chamber 12 and the filter chamber 6 are connected through a connecting pipe 27; the lid 2 on the top of the electrolysis chamber 12 is provided with an electrolyte inlet, and the electrolyte inlet is provided with a sealing cover 18. The electrolyte is 10-30% sodium hydroxide aqueous solution.

[0027] Described electrolysis chamber 12 is provided with some electrolytic plates 9 arranged in parallel, and electrolytic plate 9 ...

Embodiment 3

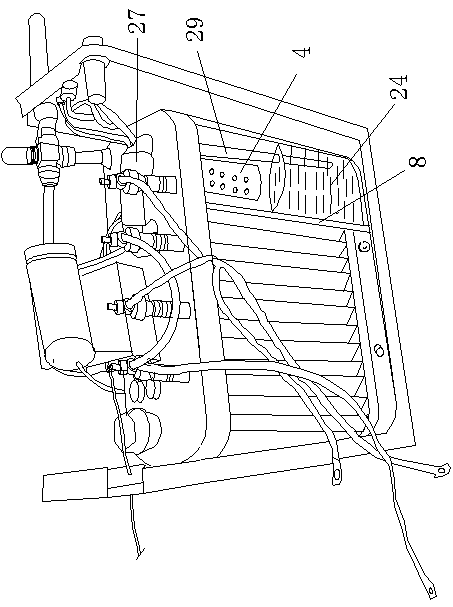

[0036] Example 3. The only difference between this embodiment and Embodiment 1 is that one end of the connecting pipe 27 located at the filter chamber 6 is connected with a conduit 29, the filter chamber 6 is equipped with filtered water 24 for filtering, and the bottom end of the conduit 29 extends into the Below the liquid level of the filtered water 24 ; the bottom of the filter 4 is located above the liquid level of the filtered water 24 .

Embodiment 4

[0037] Example 4. The only difference between this embodiment and Embodiment 1 is that the car carbon deposit cleaner includes two gas generating devices, and the filter outlet pipes of the gas generating devices are connected in parallel through a pipeline 32; the structure of the frame is a box Body structure, the box structure is provided with a box cover 31. The lines of the gas generating device are connected in parallel to the automobile power supply. This device is suitable for cleaning carbon deposits in cars with large displacement. The frame body is provided with a cooling fan 30, and the fan 30 is connected with the programmable logic controller 19 through a line. The frame adopts a box structure, which is easy to carry, easy to install and disassemble.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com