A three-dimensional wind pressure tester

A tester and wind pressure technology, applied in the direction of instruments, pressure difference measurement between multiple valves, measuring devices, etc., can solve problems such as distortion, and achieve the effect of light weight, easy installation, and good portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

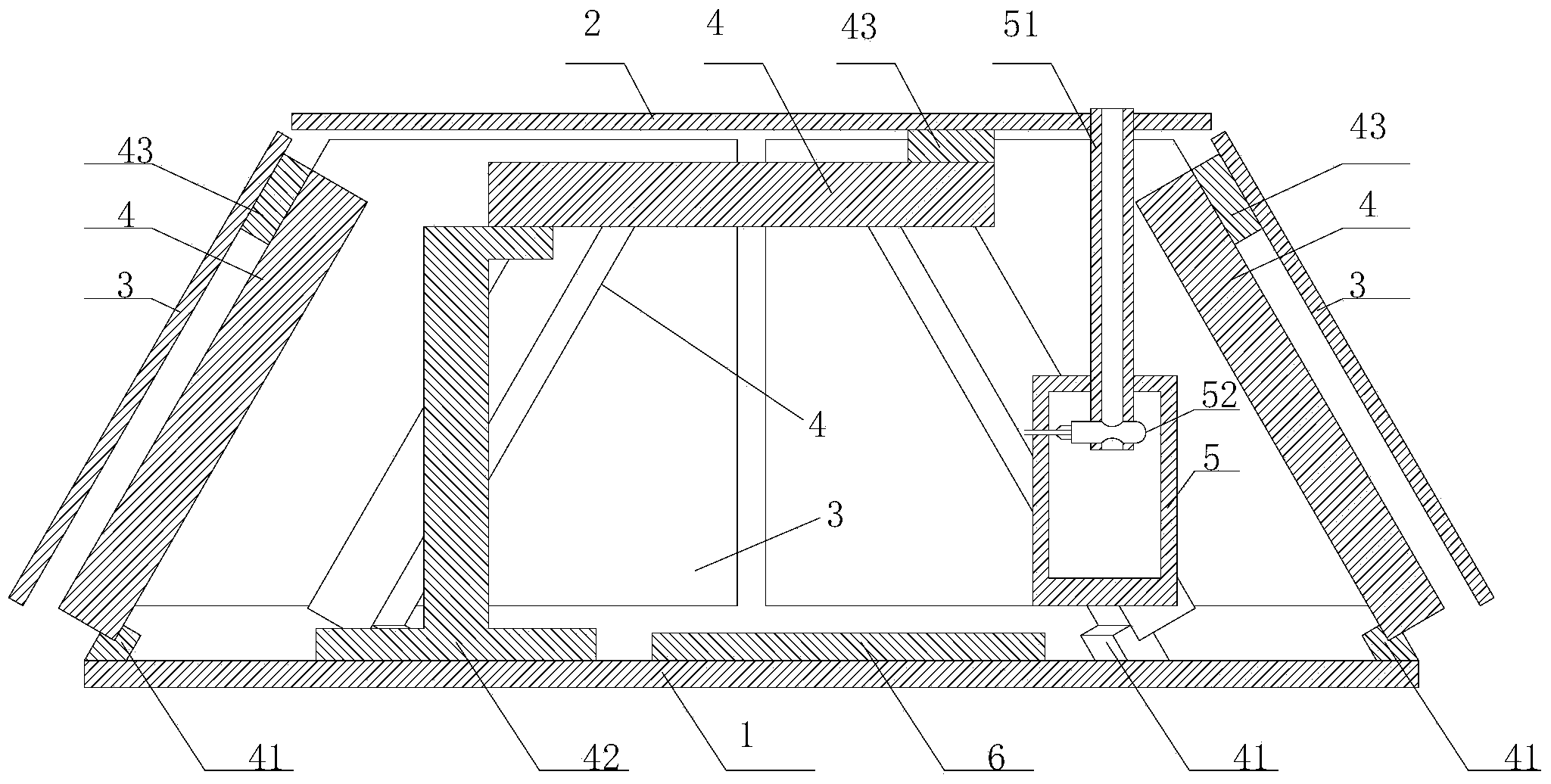

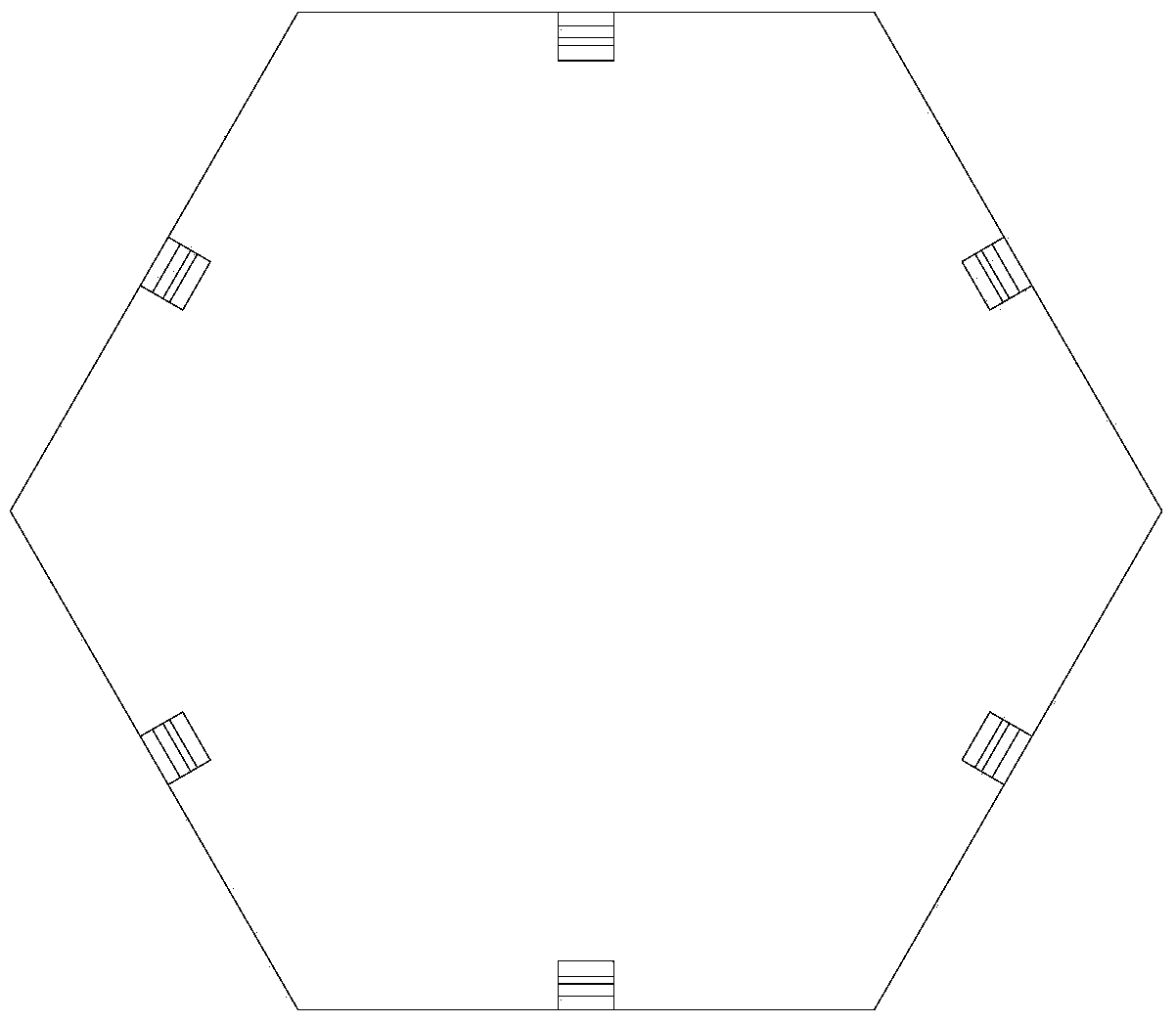

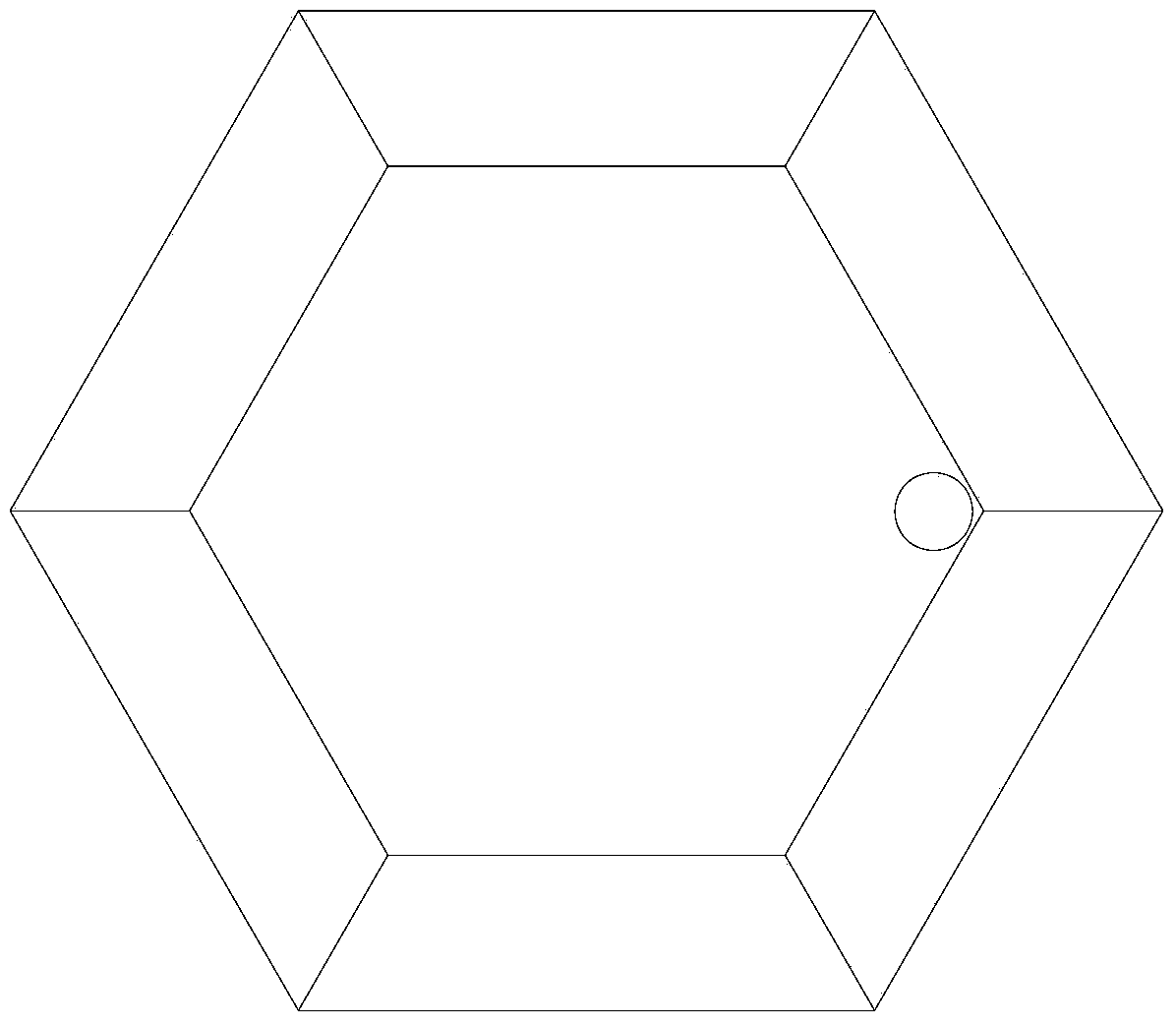

[0025] The shell includes a disc-shaped chassis 1, a regular hexagonal top loaded sheet 2, seven trapezoidal side loaded sheets 3, the chassis 1 and the side loaded sheets 3 There are gaps between the side load-bearing thin plates 3 and the top load-bearing thin plates 1 .

[0026] The chassis 1 is parallel to the top loaded sheet 2, and the angle between each side loaded sheet 3 and the chassis 1 is 60 degrees.

[0027] The bottom of the chassis 1 is equipped with a suction cup.

[0028] Between the chassis 1 and the corresponding single-arm beam mechanical sensor 4, between the top loaded thin plate 2 and the corresponding single-arm beam mechanical sensor 4, between the side loaded thin plate 3 and the corresponding single-arm mechanical sensor The connecting block 43 is glued between the boom mechanical sensors 4 .

[0029] The conduit 51 is perpendicular to the chassis 1 .

[0030] The single-chip microcomputer adopts STM32F103C8T6, has 2 Spi interfaces, 16-channel ADC...

Embodiment 2

[0037] This embodiment is carried out with reference to the wind tunnel test, and the instrument of the present invention is installed on different layers of the test building and different parts of each layer, and the instrument is numbered, and the measured data is automatically stored in the database, thereby obtaining the actual wind pressure of the building, and It can be compared with the data obtained from the wind tunnel test.

[0038] The content described in the embodiments of this specification is only an enumeration of the implementation forms of the inventive concept. The protection scope of the present invention should not be regarded as limited to the specific forms stated in the embodiments. The protection scope of the present invention also includes those skilled in the art. Equivalent technical means conceivable according to the concept of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com