Deodorizing device with flaky filler

A technology of flake packing and air distribution device, which is applied in the direction of dispersed particle separation, air quality improvement, chemical instruments and methods, etc., to achieve the effects of reducing residence time, reducing the volume of deodorizing equipment, and maintaining activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

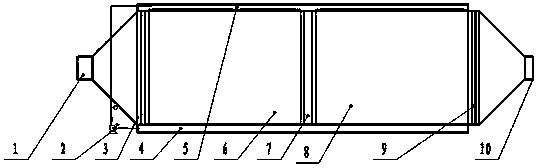

[0027] A deodorizing device with flaky fillers, which uses secondary flaky fillers for deodorization, and the device includes an air inlet, a circulating water system, an inlet air distribution device, a bottom pool, and a top water distribution and moisturizing device , first-level sheet packing, second-level sheet packing, outlet air distribution device and air outlet, wherein the circulating water system is set on the side of the deodorization device, the air inlet is set at one end of the deodorization device, and the other end is set at the air outlet , the air inlet is connected to the air inlet distribution device, and the gas entering from the air inlet must pass through the air inlet distribution device, so that the odor to be treated can pass through the first-stage sheet packing at a uniform speed, so that the odor to be treated can be fully In contact with the biofilm on the first-stage sheet packing, an intermediate gas distribution device is installed between the ...

Embodiment 2

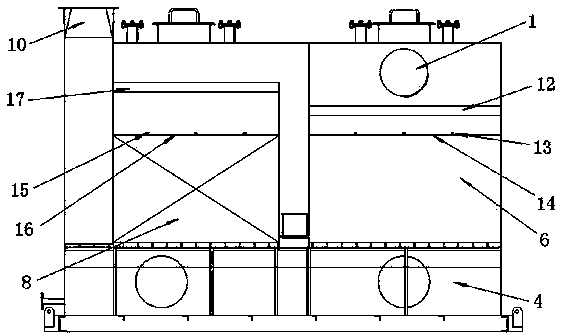

[0031] The deodorization device includes an air inlet, a first-stage sheet packing air distribution and water supply device, a bottom pool, a first-stage sheet packing, a second-stage sheet packing, a second-stage sheet packing air distribution and water supply device, and an air outlet. The upper end of the first-level flake packing air distribution and water supply device is connected to the air inlet. The filler is suspended on the main beam and the first-level sheet-like filler is suspended on the support beam, and a gap is set between the first-level sheet-like filler and the second-level sheet-like filler, and a bottom pool is set at the lower end of the first-level sheet-like filler and the second-level sheet-like filler. Set the air distribution and water supply device of the secondary sheet packing at the upper end of the secondary sheet packing, and set the secondary sheet packing suspension main beam and the secondary sheet packing suspension The support beam and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com