Machining method and machining die for T iron with high wire diameter ratio

A processing method and a technology for processing molds, which are applied in the direction of manufacturing tools, metal processing equipment, mechanical equipment, etc., can solve the problems of multiple processes and high production costs, and achieve the effects of improving production efficiency, good dimensional stability, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

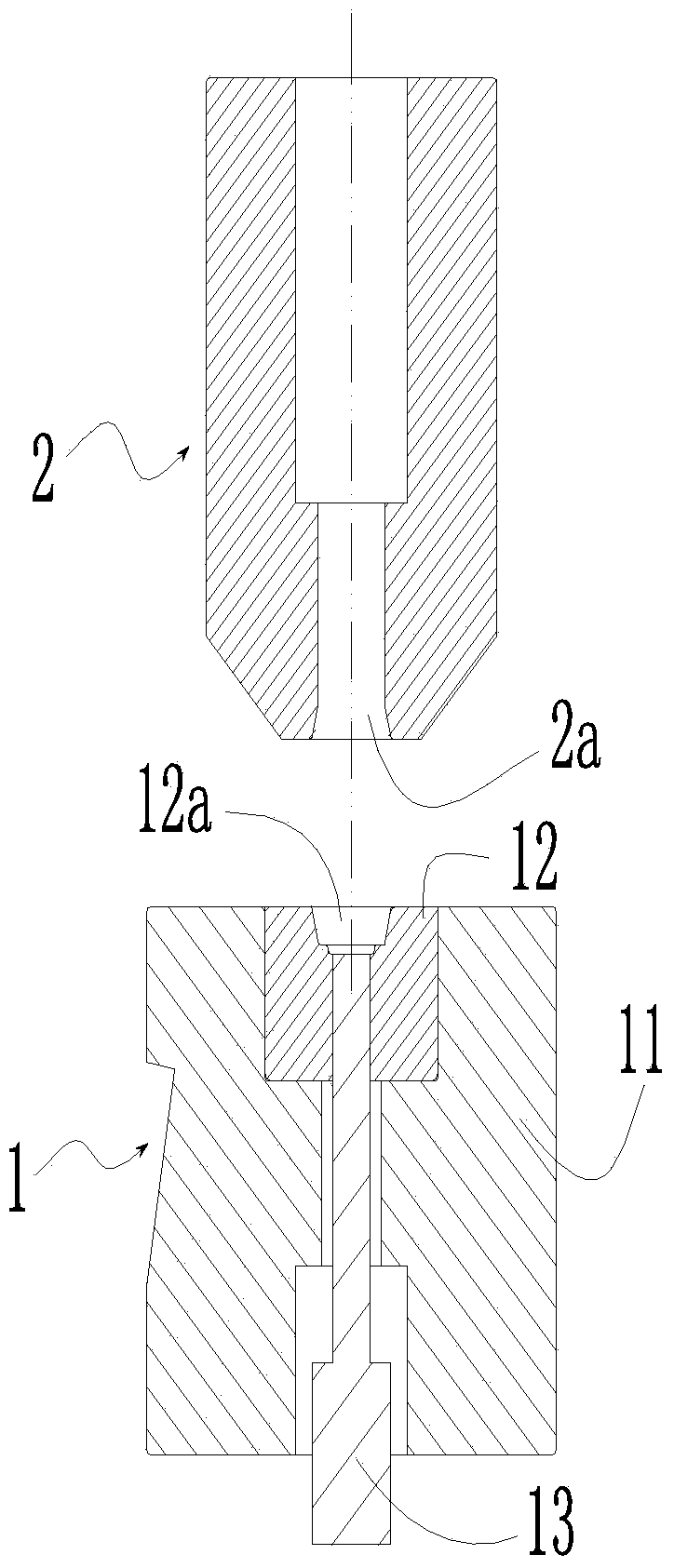

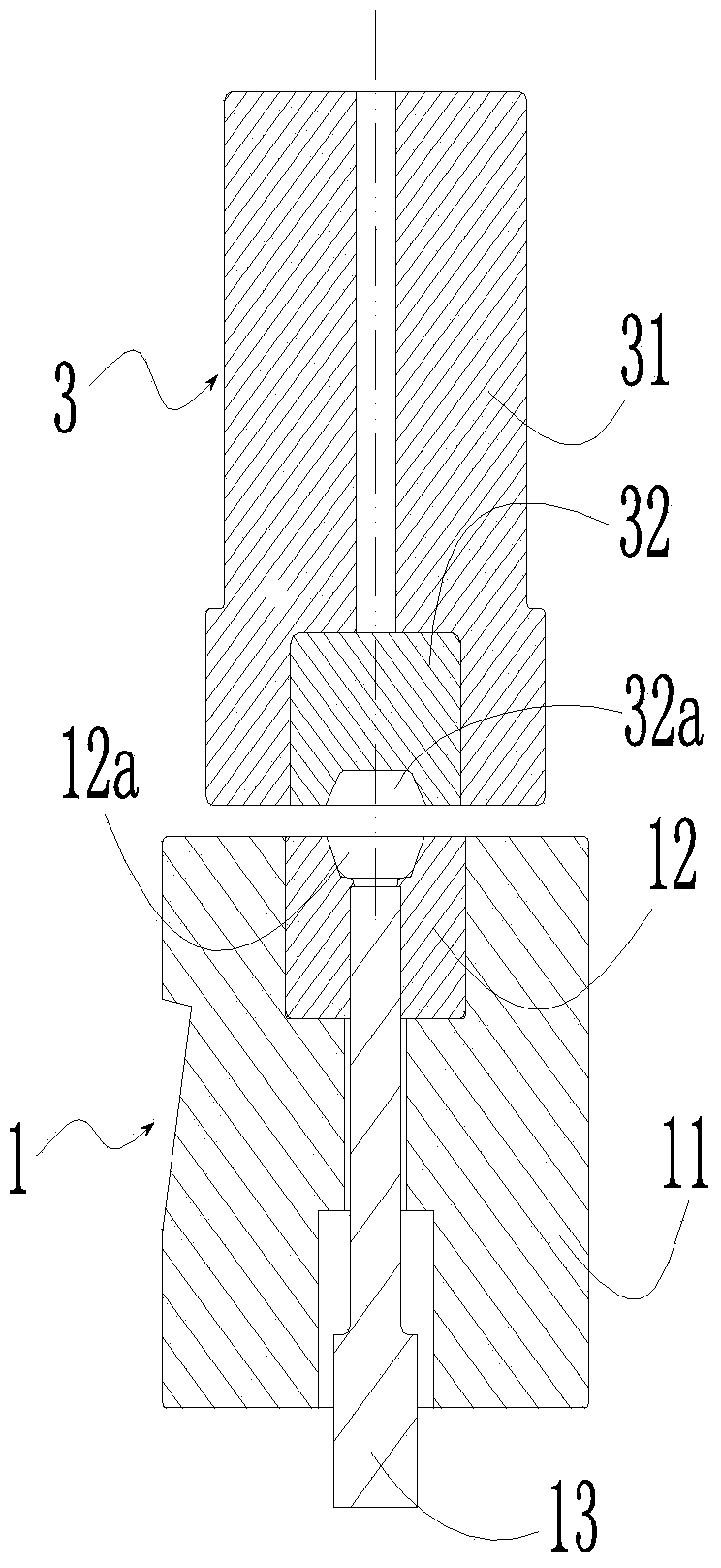

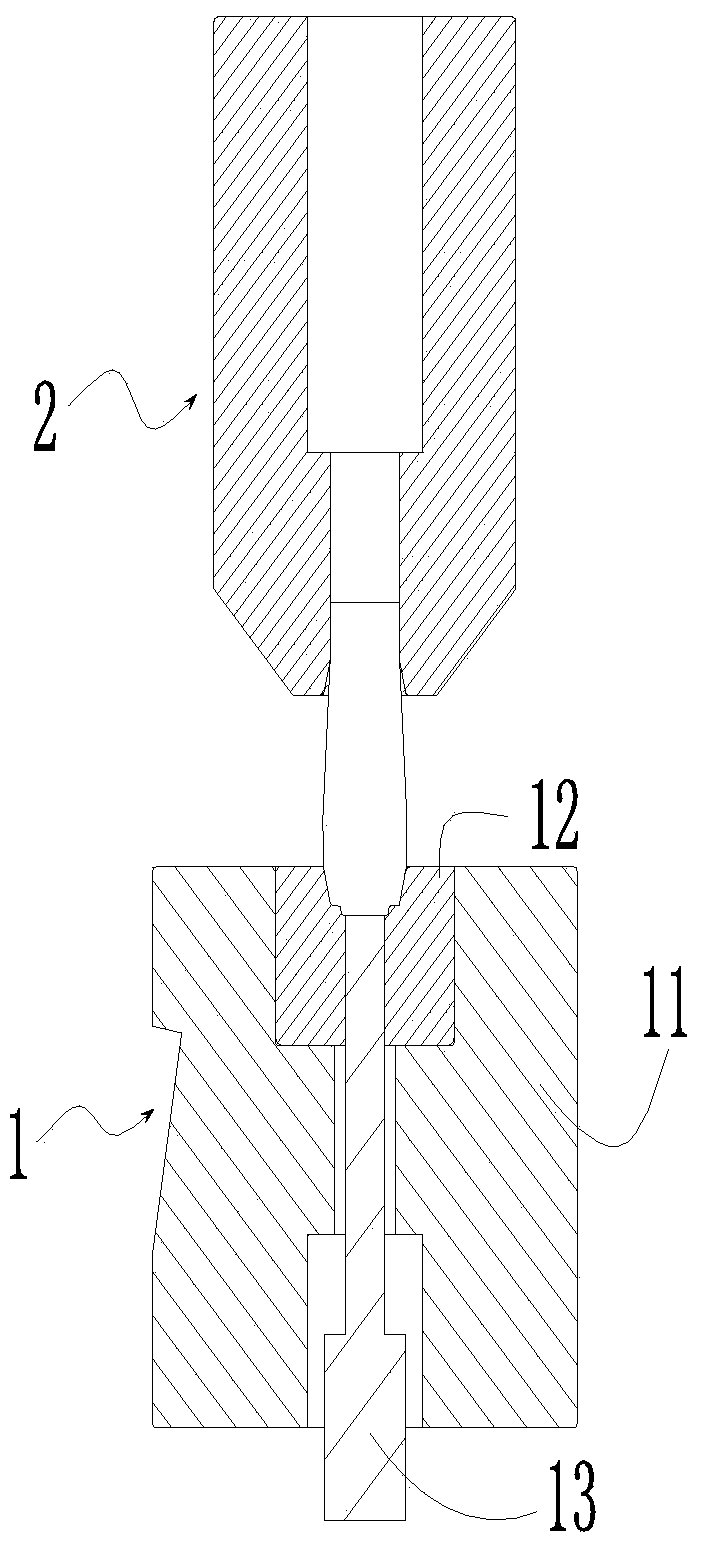

[0025] A kind of processing method of high wire diameter ratio T iron of the present invention, comprises the following steps:

[0026] (1) Calculate and select rods of reasonable diameter according to the requirements of T iron and cut them into blanks. The calculation is based on the weight and size of T iron, and usually a rod with a larger diameter is selected as the blank.

[0027] (2) Put the blank into the lower die installed in the circular shear heading machine, first use a punch to extrude the positioning foot of the workpiece, and then use the positioning foot to position, so that the material bar is stuck in the lower die, and a punch returns After that, convert it into a second punch and punch it quickly to form a mushroom head shape.

[0028] (3) Putting the headed blank obtained in step (2) into a flattening die for flattening treatment.

[0029] (4) The flattened blank obtained in step (3) is put into a forming die for forming.

[0030] The high wire-diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com