Method for improving laser preprocessing efficiency of optical element small light spot scanning

A technology for scanning lasers and optical components, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of time-consuming and limiting the working efficiency of small-spot scanning preprocessing systems of optical components, and improve efficiency and methods simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with example and accompanying drawing, but should not limit the protection scope of the invention with this.

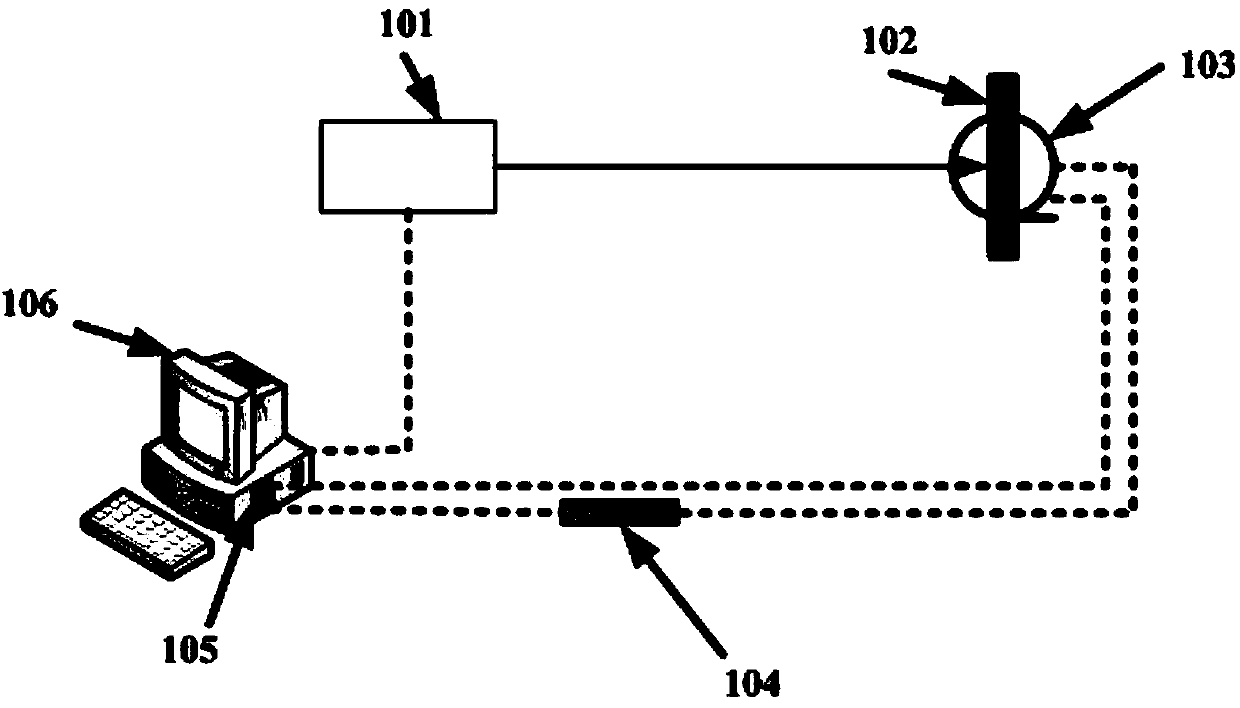

[0020] see figure 1 . figure 1 It is a schematic diagram of the optical element small spot scanning laser pretreatment system adopted by the method of the present invention. In the figure, 101—laser, 102—sample, 103—servo motor, 104—motor driver, 105—movement board, 106—computer.

[0021] The laser 101 outputs laser light, the sample 102 is fixed on the servo motor 103, and the computer 106 controls the motor driver 104 to drive the servo motor 103 to move through the motion board 105, thereby controlling the motion speed and the motion track of the sample 102. At the same time, the The computer obtains the motion situation of the servo motor 103 through the motion board 105, that is, obtains the position information of the sample 102 motion track in real time, and the motion board 105 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com