Device and method for manufacturing large-size mandrel loose body

A technology for manufacturing a device and a loose body, applied in the field of optical fibers, can solve the problems of product loss, cracking of the loose body, large density change, etc., and achieves the effect of saving money and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

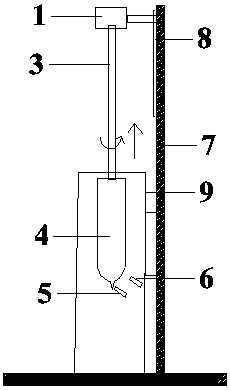

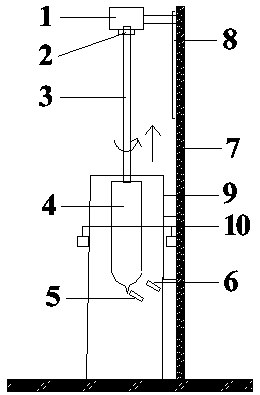

[0024] see figure 1 with 2 , the meanings of the reference signs are: 1 is a servo motor, 2 is a weight detection device, 3 is a quartz glass base rod, 4 is a core rod loose body, 5 is a core blowtorch, 6 is a cladding blowtorch, 7 is a tower, 8 is guide rail, 9 is a deposition box, and 10 is a diameter measuring device. exist figure 2 Among them, the weight detection device is installed on the rotary chuck of the servo motor, which slides synchronously with the servo motor 1 on the guide rail 8, and is used to detect the total weight of the loose body; the diameter detection device is installed on both sides of the deposition box, and detects during the deposition process The diameter of the loose body. The density on-line monitoring device in the present invention includes a weight detection device and a diameter measurement device.

[0025] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com