Alpha type hemihydrate gypsum composite waterproof agent

A technology of hemihydrate gypsum and water repellent, which is applied in the field of composite water repellent, can solve the problem of high price, and achieve the effect of improving the waterproof effect, increasing the mechanical properties and good waterproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Mix 6kg of acrylate and 3.1kg of vinyl acetate with water, add a small amount of surfactant alkylphenol polyoxyethylene ether, heat up to 50-70°C and stir at high speed for 20-30min, then keep warm for 1-2h; add 6kg of acrylate again , 3.1kg of vinyl acetate and 2.0kg of emulsifier azobisisobutylcyanide, heated to 85°C and stirred for 30-45min, then kept warm for 1-3h, lowered to room temperature and adjusted to pH 7.2-8, filtered to obtain a waterproofing agent Stand by after use. Add the above-mentioned self-made waterproofing agent, 3.3kg of slag powder and 3.8kg of treated straw into water and mix evenly, then add 1000kg of α-type hemihydrate gypsum into it, stir for 2-5min, pour into the mold, and remove the mold after curing. α-type hemihydrate gypsum products.

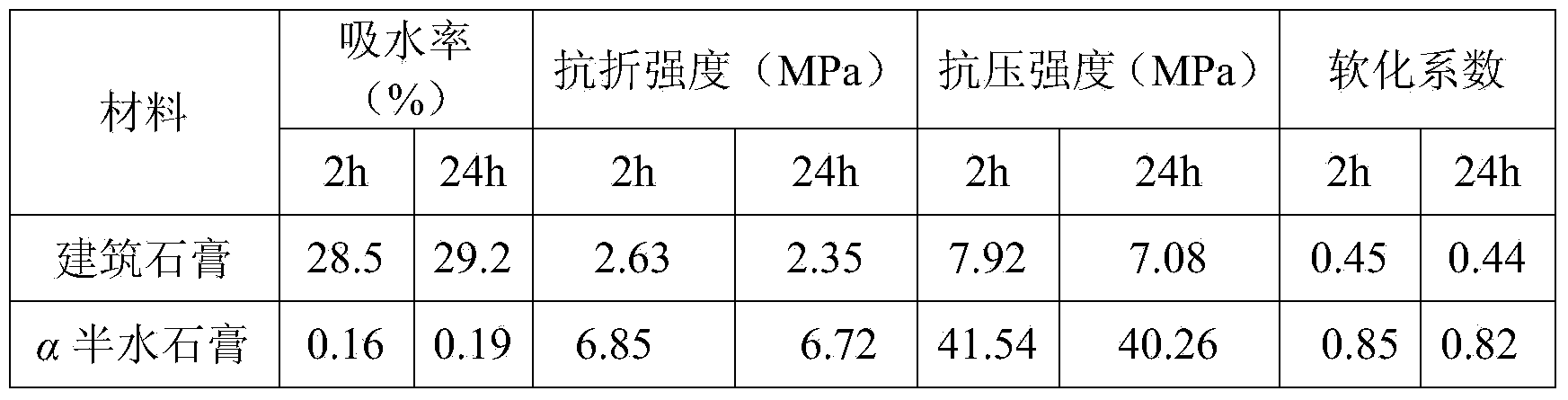

[0027] The experimental results are as follows:

[0028]

Embodiment 2

[0030] Mix 22.5kg of acrylate, 4kg of vinyl acetate, and 1.5kg of isocyanate with water, add a small amount of surfactant alkylphenol polyoxyethylene ether 1kg, heat up to 50-70°C and stir at high speed for 20-30min, then keep warm for 1-2h; Add 22.5kg of acrylate, 3.5kg of vinyl acetate, 1.3kg of isocyanate and 2.2kg of emulsifier polyvinyl alcohol, heat to 85°C and stir for 30-45min, keep warm for 1-3h, lower to room temperature and adjust pH to 7.2-8 , filter, and prepare the waterproofing agent for later use. Add the above-mentioned self-made waterproofing agent, 4.2kg of slag powder, 2.8kg of fly ash, and 4.5kg of treated straw into water and mix evenly, then add 1000kg of α-type hemihydrate gypsum into it, stir for 2-5min, pour into the mold, and The α-type hemihydrate gypsum product is obtained by curing and demoulding.

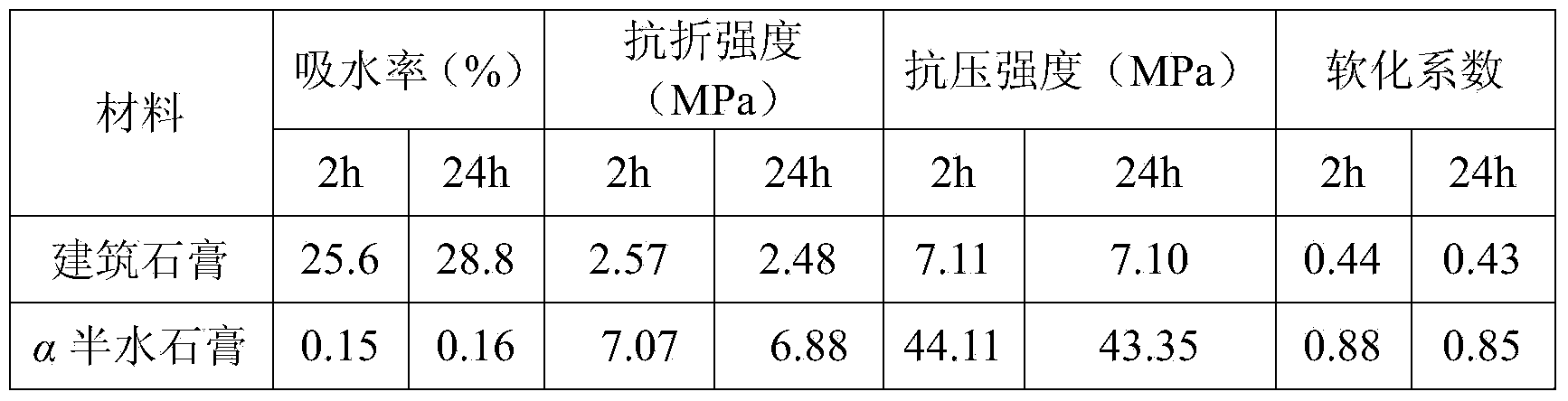

[0031] The experimental results are as follows:

[0032]

Embodiment 3

[0034] Mix 3kg of isocyanate and 12kg of vinyl acetate with water, add a small amount of surfactant alkylphenol polyoxyethylene ether 4.5kg, heat up to 50-70°C and stir at high speed for 20-30min, then keep warm for 1-2h; add 3kg of isocyanate again, Vinyl acetate 12kg and emulsifier polyvinyl alcohol 4.2kg, heated to 85°C and stirred for 30-45min, then kept warm for 1-3h, lowered to room temperature and adjusted to pH 7.2-8, filtered to prepare waterproofing agent for use . Add the above self-made waterproofing agent, 7.2kg of slag powder and 3.6kg of fly ash, 2.8kg of treated citrus peel, 2.5kg of sugarcane peel into water and mix evenly, then add 1000kg of α-type hemihydrate gypsum into it, stir for 2-5min and pour Put it into the mold, and make α-type hemihydrate gypsum products after curing and demoulding.

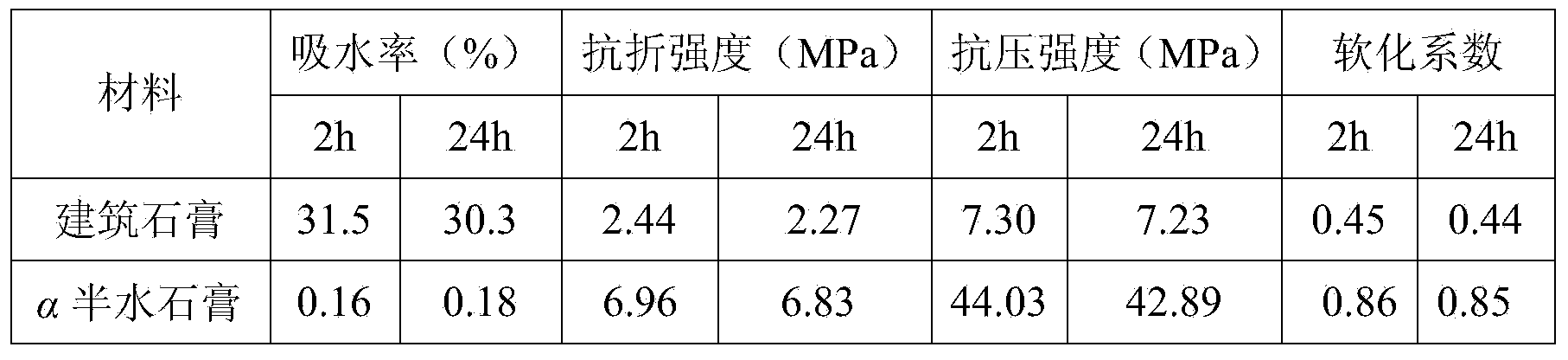

[0035] The experimental results are as follows:

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com