Functional chitosan biological slow-release fertilizer and preparation method thereof

A chitosan and slow-release fertilizer technology, applied in the field of functional chitosan bio-slow-release fertilizer, can solve the problems of fertilizer utilization rate to be improved, high price, difficult to popularize and apply, etc., and achieve remarkable nutrient slow-release effect , Process requirements are simple, the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Functional chitosan biological slow-release fertilizer (N-P 2 o 5 -K 2 O: 28-6-6, slow and controlled release of nitrogen accounted for 60% of the total nitrogen) preparation method

[0037] (1) In the reaction kettle, add 15kg industrial starch and 71kg distilled water, heat up to 70°C-80°C under stirring, gelatinize and stir for 30min, then add 8kg polyvinyl alcohol, 3kg chitosan, 2kg butyraldehyde (concentration 98 %), 1kg of di-n-hexyl adipate, heated up to 90°C-95°C under stirring, and the constant temperature reaction time is 60min-90min, and an environmentally friendly and biodegradable chitosan coating material is formed.

[0038](2) Screen and weigh 365kg of large-grain urea fertilizer with a particle size of 2.2mm-4.2mm, pour it into a fluidized bed drum coating machine, preheat it to 80°C-90°C in the preheating zone, and enter the fluidized coating Area. In the fluidized coating area, the preheated large-grained urea is lifted to the top of the drum by th...

Embodiment 2

[0041] Functional chitosan biological slow-release fertilizer (N-P 2 o 5 -K 2 O: 26-12-10, slow and controlled nitrogen release accounts for 69% of the total nitrogen) preparation method

[0042] (1) In the reaction kettle, add 20kg industrial starch and 60kg distilled water, heat up to 70°C-80°C under stirring, gelatinize and stir for 30min, then add 10kg polyvinyl alcohol, 5kg chitosan, 4kg butyraldehyde (concentration 98 %), 1kg of di-n-hexyl adipate, heated up to 90°C-95°C under stirring, and the constant temperature reaction time is 60min-90min, and an environmentally friendly and biodegradable chitosan coating material is formed.

[0043] (2) Screen and weigh 390kg of large-grain urea fertilizer with a particle size of 2.2mm-4.2mm, pour it into a fluidized bed drum coating machine, preheat it to 80°C-90°C in the preheating zone, and enter the fluidized coating Area. In the fluidized coating area, the preheated large-grained urea is lifted to the top of the drum by th...

Embodiment

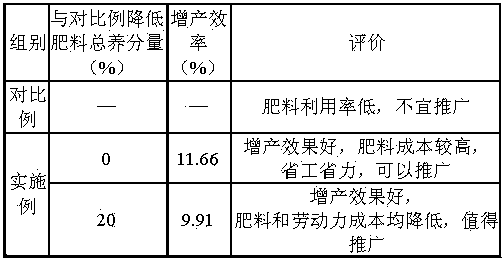

[0047] Embodiment: functional chitosan biological slow-release fertilizer (28-6-6, produced by Stanley Company)

[0048] The corn variety is "Denghai 618"

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com