Method for improving wear resistance of PTFE

A technology of wear resistance and PTFE, which is applied in the production field of polytetrafluoroethylene, can solve problems such as increased molecular weight, lowered melting point, and differences in processing technology, and achieves the effect of simple process, simple method, and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

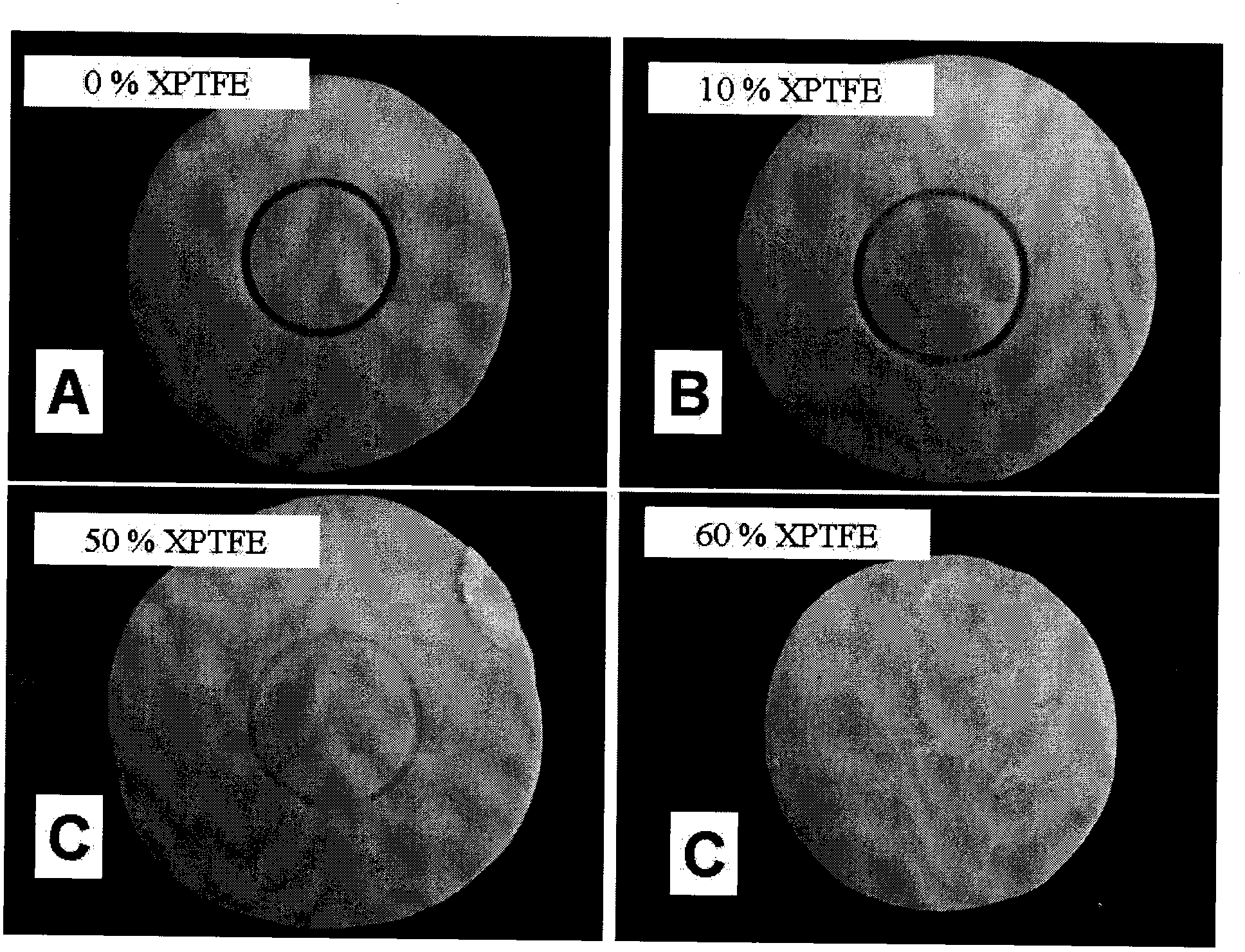

Embodiment 1

[0014] A kind of method that this embodiment provides to improve PTFE wear resistance, 450 grams of suspended PTFE raw materials (molecular weight more than 8,000,000) and 50 grams of cross-linked PTFE are fully mixed in a mixing machine to prepare a modified material containing 10% cross-linked PTFE PTFE. Take 100 grams of the sample and press it into a disc with a diameter of 5 cm in a mold. In addition, 100 grams of suspended PTFE raw materials were pressed into discs with a diameter of 5 cm under the same conditions as control sample 1. The PTFE disc is subjected to a friction test on a MMW-1A friction and wear testing machine, the test temperature is room temperature, the pressure is 100 Newton, and the time is 60 minutes. After the test, the wear rate of the test is calculated by accurately weighing the mass of the PTFE disc. The friction coefficient of the PTFE sample is 0.22, and the mass wear is 0.32 grams; the friction coefficient of the control PTFE sample under t...

Embodiment 2

[0020] A method for improving the wear resistance of PTFE described in this example is to fully mix 250 grams of suspended PTFE raw materials (more than 8 million molecular weight) with 250 grams of XPTFE (cross-linked PTFE) in a mixing machine, and the selected XPTFE has a melting point of 314 ° C. High wear-resistant XPTFE, thus preparing modified PTFE containing 50% cross-linked PTFE. Take 100 grams of the sample and press it into a disc with a diameter of 5 cm in a mold. The PTFE disc is subjected to a friction test on a MMW-1A friction and wear testing machine, the test temperature is room temperature, the pressure is 100 Newton, and the time is 60 minutes. After the test, the wear rate of the test is calculated by accurately weighing the mass of the PTFE disc. The coefficient of friction of the PTFE sample is 0.248, and the mass wear is 0.075 grams; Therefore, after adding 50% cross-linked PTFE, the friction coefficient increases by about 20%, and the wear decreases by...

Embodiment 3

[0022] A kind of method for improving the wear resistance of PTFE described in this embodiment, 200 grams of suspended PTFE raw materials (more than 8 million molecular weight) and 300 grams of cross-linked PTFE are fully mixed in a mixing machine to prepare modified modified PTFE containing 60% cross-linked PTFE PTFE. Take 100 grams of the sample and press it into a disc with a diameter of 5 cm in a mold. The PTFE disc is subjected to a friction test on a MMW-1A friction and wear testing machine, the test temperature is room temperature, the pressure is 100 Newton, and the time is 60 minutes. After the test, the wear rate of the test is calculated by accurately weighing the mass of the PTFE disc. The coefficient of friction of this PTFE sample is 0.248, and the mass wear is zero. Therefore, after adding 60% cross-linked PTFE, the friction coefficient increases by about 20%, and the wear decreases by 100%. This shows that the 60% cross-linked PTFE added to the test piece ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com