Quick sealing method for excavating phyllite stratum tunnel

A technology of tunnel excavation and phyllite, which is applied in the direction of tunnels, tunnel linings, underground chambers, etc., can solve the problems of long time for full-section sealing and ring formation, affecting construction progress and safety, and prone to large deformation. Achieve high promotion and application value, speed up construction progress, and control tunnel deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

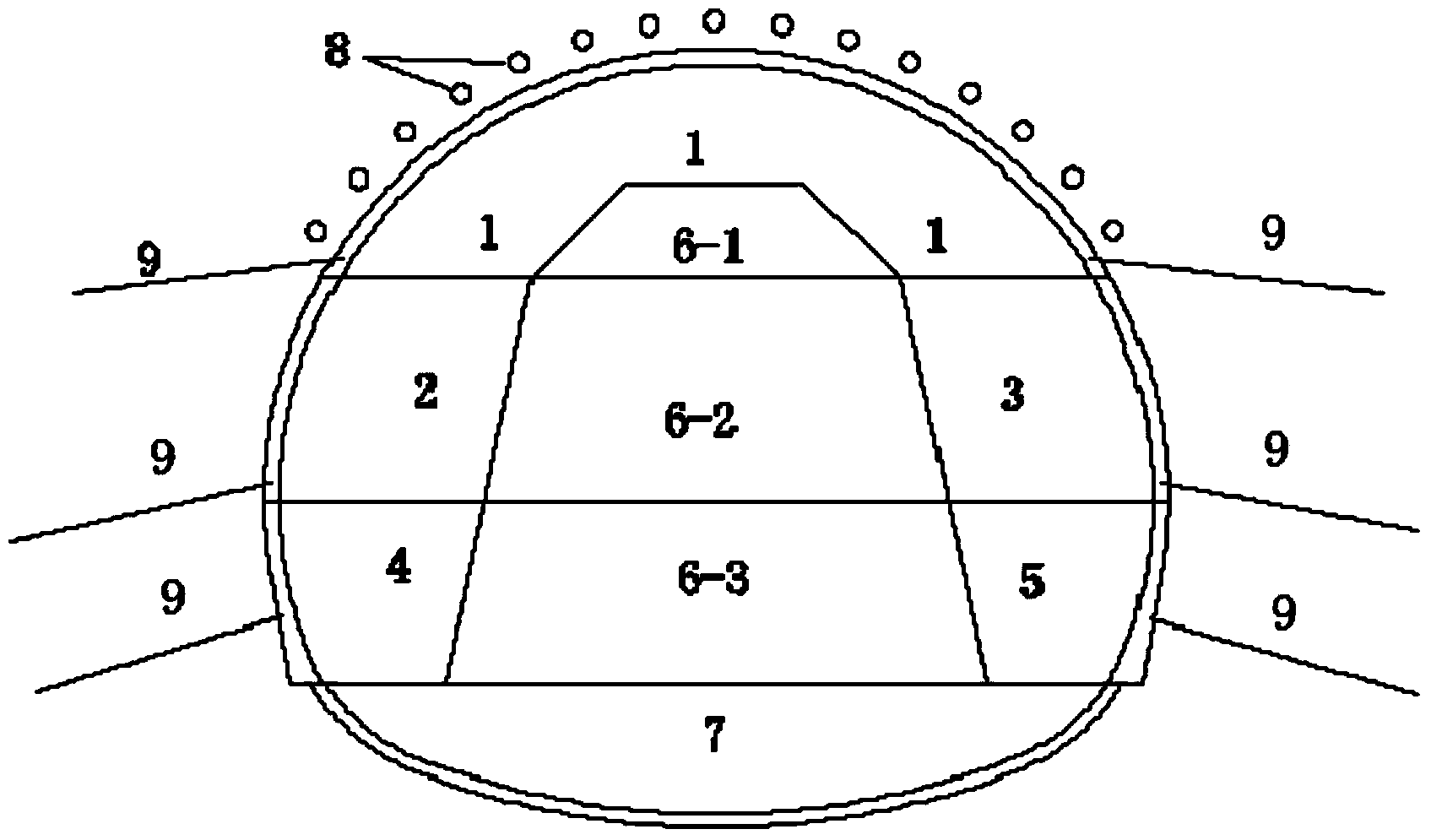

[0016] Such as figure 1 As shown, the rapid sealing method for phyllite tunnel excavation includes the following steps:

[0017] (1) Use the upper circulation to erect the steel frame to make the small ahead conduit and inject grout.

[0018] (2) Excavate one part of the upper step in sections by means of machinery combined with manual or weak blasting, and implement initial support around the first part of the upper step, with a footage length of 1 block. The steel frame lock foot bolts are mortar bolts with L=8m and diameter Φ22, two on the left and two on the right. After the initial support concrete reaches the required strength, carry out radial grouting on part 1.

[0019] (3) Lag behind part 1 for a distance and staggered excavation for steps 2 and 3, perform initial support, and the footage length per cycle is 3 blocks. Two mortar anchors with L=8m and diameter Φ22 are used for the steel frame lock foot anchors. After the initial support concrete reaches the requir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com