Roadway full-fracture-surface anchoring-rod and anchoring-rope integrated parallel installation method and device

A parallel installation, full-section technology, applied in the installation of bolts, earth-moving drilling, mining equipment, etc., can solve the problems of greater mutual interference, complex systems, hidden safety hazards, etc., to achieve a simple and compact structure, a wide range of adaptation conditions, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

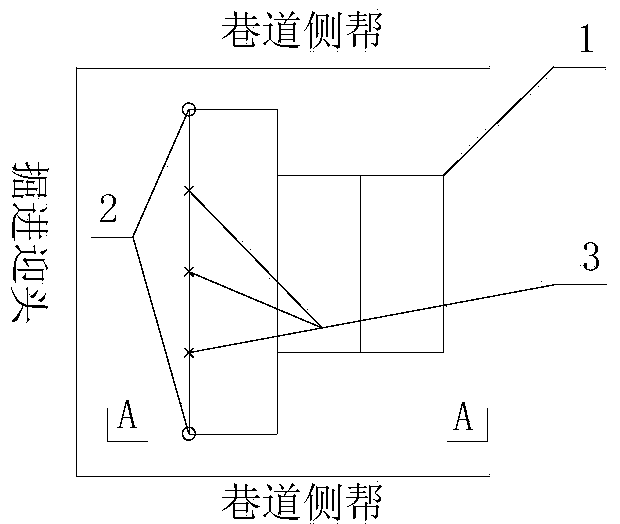

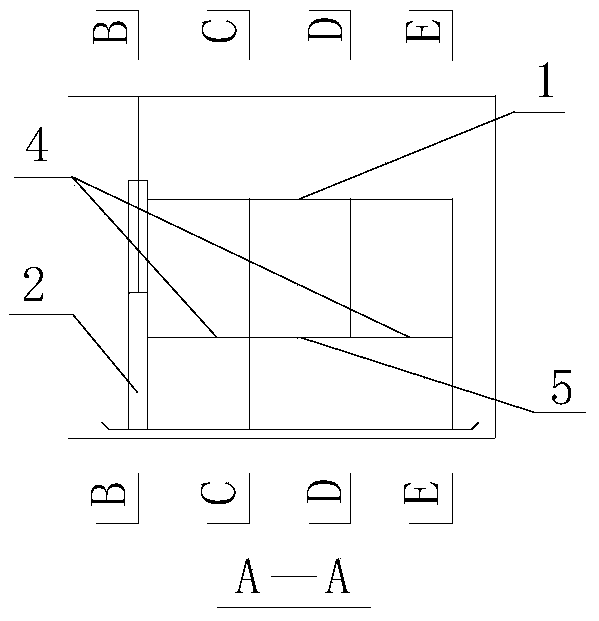

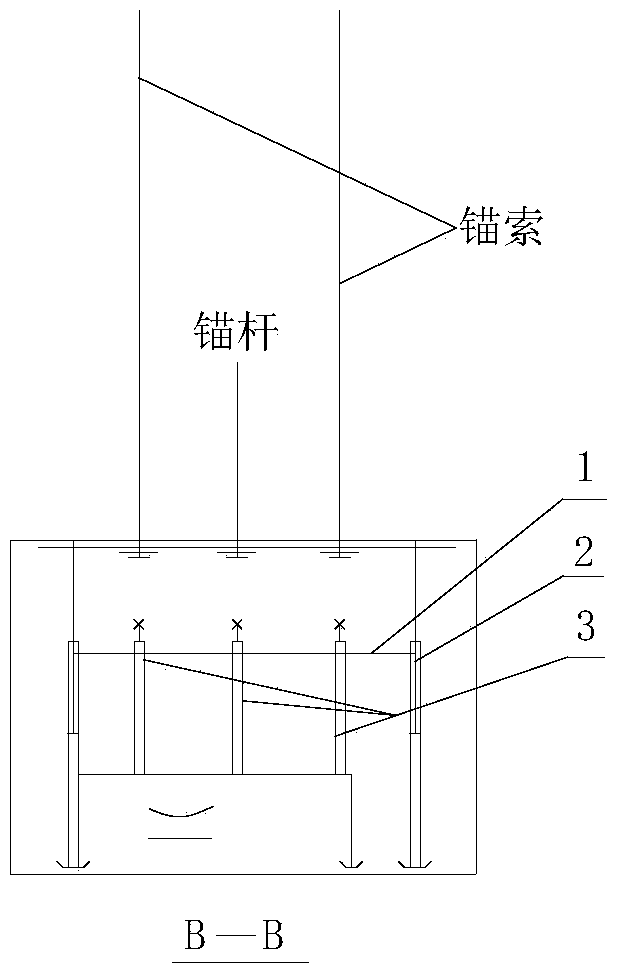

[0040] The present invention is described in detail below in conjunction with accompanying drawing:

[0041] The device is based on dividing the excavation working face into the working area of the roadheader, that is, the temporary support area and the permanent support area; The protection area uses this technology and device for permanent support, realizing simultaneous operation of permanent support and roadheader cutting, simultaneous operation of anchor rods and anchor cables, and full sections of anchor rods and anchor rods, and anchor cables and anchor cables. Operation. According to the specific position of the anchor rod and anchor cable in the roadway support design, a drilling rig is arranged for each anchor rod and anchor cable, and these drilling rigs are fixed on a movable frame. The relative position in the roadway is always kept unchanged, so that each anchor rod and anchor cable can be placed in place in one step and constructed at the same time; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com