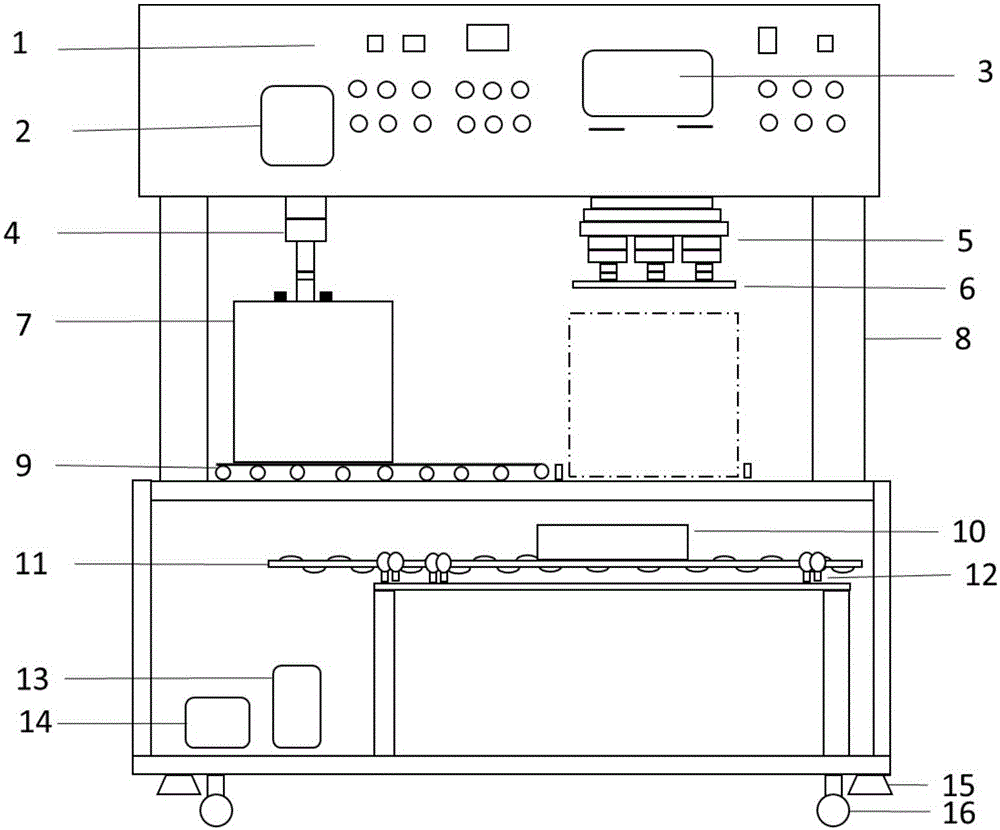

Hydraulic stirring device and method for preparing immobilized microorganisms

A technology of immobilized microorganisms and hydraulic devices, applied in the field of machinery, to achieve the effects of high efficiency, wide range of adaptation conditions, and low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

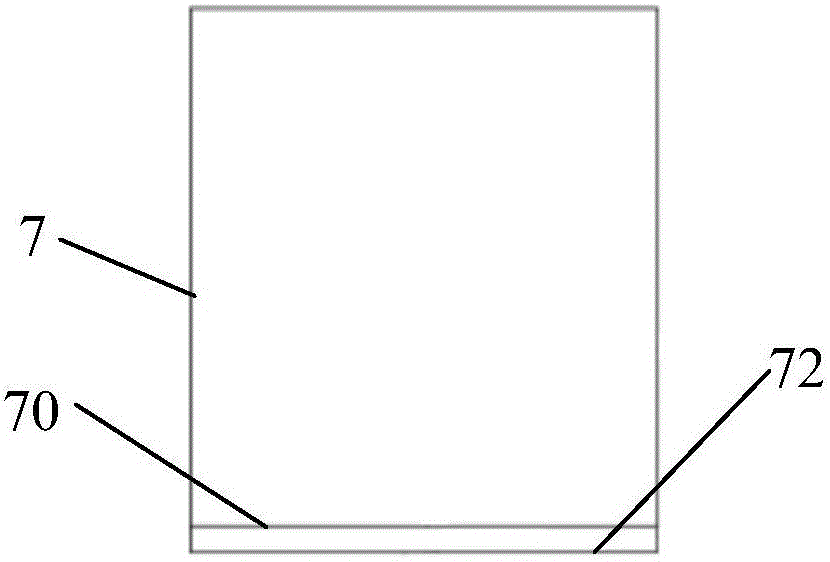

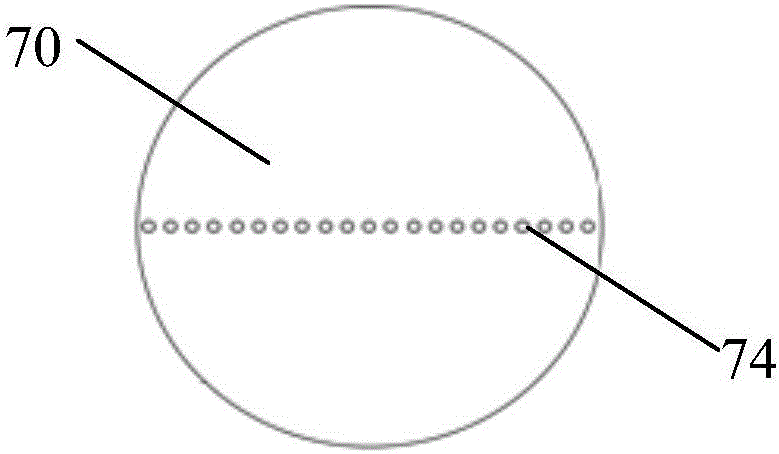

[0050] This embodiment provides a device for preparing immobilized microorganisms, wherein the material cylinder 7 is 600mm deep, the cylinder wall thickness is 25mm, the bottom plate diameter is 360mm, and the hole diameter of the hollow bottom plate is 5mm; the binder plate thickness is 30mm, and the hydraulic process control pressure is 7 tons. The operation method includes the following steps:

[0051] (1), inject 2 / 3 of water in the material tank 7, turn on the stirring motor 2, adjust the stirring rate to 500r / min, then add 5% polyvinyl alcohol, and stir at a rate of 500r / min for 30min until uniformly mixed;

[0052] (2), continue to add other carrier materials in the material tank, stir at a stirring rate of 1000r / min for 20min, until the microorganism immobilized carrier is obtained after mixing evenly;

[0053] (3), continue to add 40% microbial bacterial agent in the material cylinder, and stir 20min under the stirring speed of 600r / min, obtain the microbial materia...

Embodiment 2

[0058] This embodiment provides a device for preparing immobilized microorganisms, wherein the material cylinder 7 is 500mm deep, the cylinder wall thickness is 25mm, the bottom plate diameter is 360mm, and the hole diameter of the hollow bottom plate is 3mm; the binder plate thickness is 30mm, and the hydraulic process control pressure is 7 tons. The operation method includes the following steps:

[0059] (1), inject 2 / 3 of water in the material tank 7, turn on the stirring motor 2, adjust the stirring rate to 500r / min, then add 5% polyvinyl alcohol, and stir at a rate of 500r / min for 30min until uniformly mixed;

[0060] (2), continue to add other carrier materials in the material tank, stir at a stirring rate of 1000r / min for 20min, until the microorganism immobilized carrier is obtained after mixing evenly;

[0061] (3), continue to add 40% microbial bacterial agent in the material cylinder, and stir 20min under the stirring speed of 600r / min, obtain the microbial materia...

Embodiment 3

[0066] This embodiment provides a device for preparing immobilized microorganisms, wherein the material cylinder 7 is 1000mm deep, the cylinder wall thickness is 25mm, the bottom plate diameter is 360mm, and the hole diameter of the hollow bottom plate is 10mm; the pressure plate is 30mm thick, and the hydraulic process control pressure is 7 tons. The operation method includes the following steps:

[0067] (1), inject 2 / 3 of water in the material tank 7, turn on the stirring motor 2, adjust the stirring rate to 500r / min, then add 5% polyvinyl alcohol, and stir at a rate of 500r / min for 30min until uniformly mixed;

[0068] (2), continue to add other carrier materials in the material tank, stir at a stirring rate of 1000r / min for 20min, until the microorganism immobilized carrier is obtained after mixing evenly;

[0069] (3), continue to add 40% microbial bacterial agent in the material cylinder, and stir 20min under the stirring speed of 600r / min, obtain the microbial materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com