Hydrogen purification device for fuel cell engine

A fuel cell and engine technology, applied in fuel cells, electrical components, electrochemical generators, etc., can solve the problems of complex purification device procedures, difficult adsorption control, unfavorable portability and movement, etc., to expand the source of hydrogen and adapt to a wide range of conditions , The effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] An embodiment of the present invention discloses a hydrogen purification device for a fuel cell engine, including a solid-state electrochemical reactor and a controller.

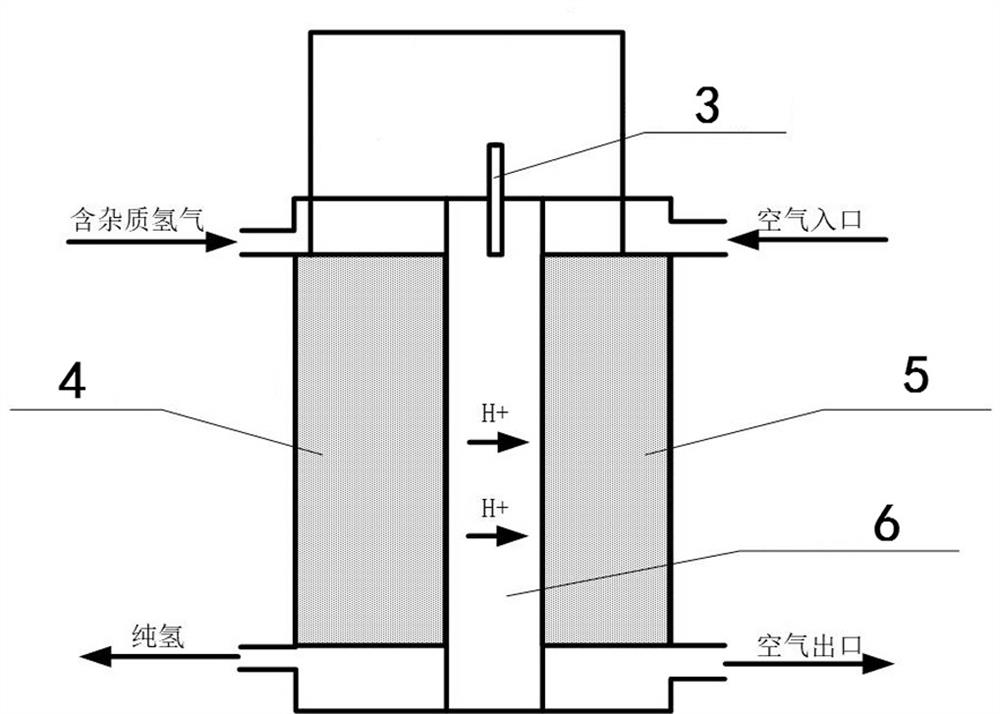

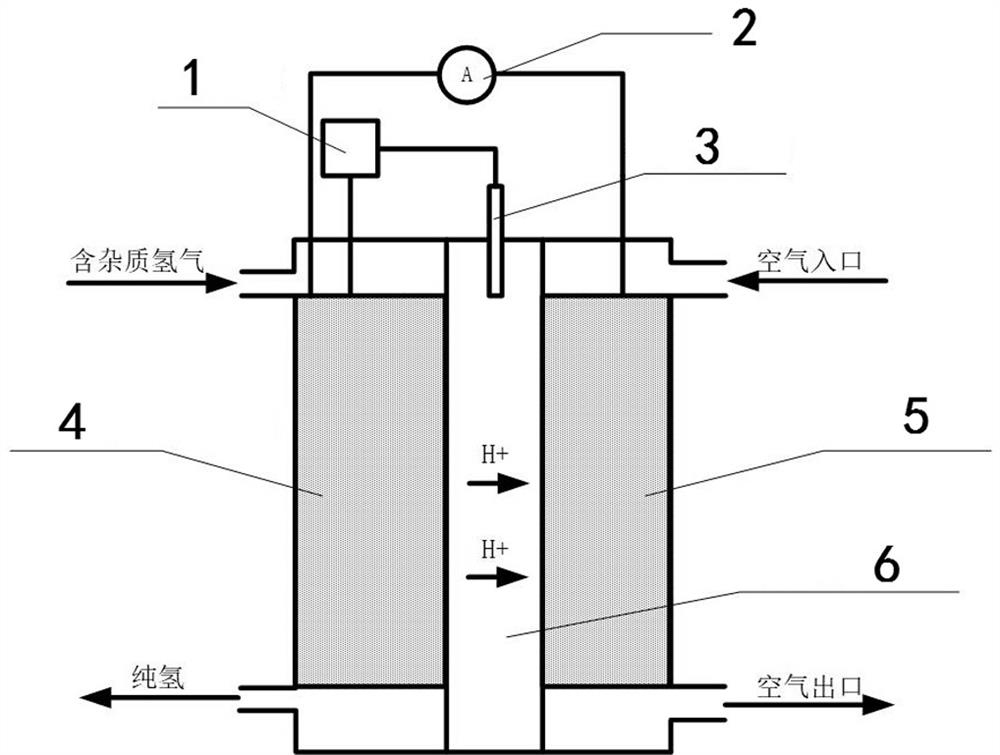

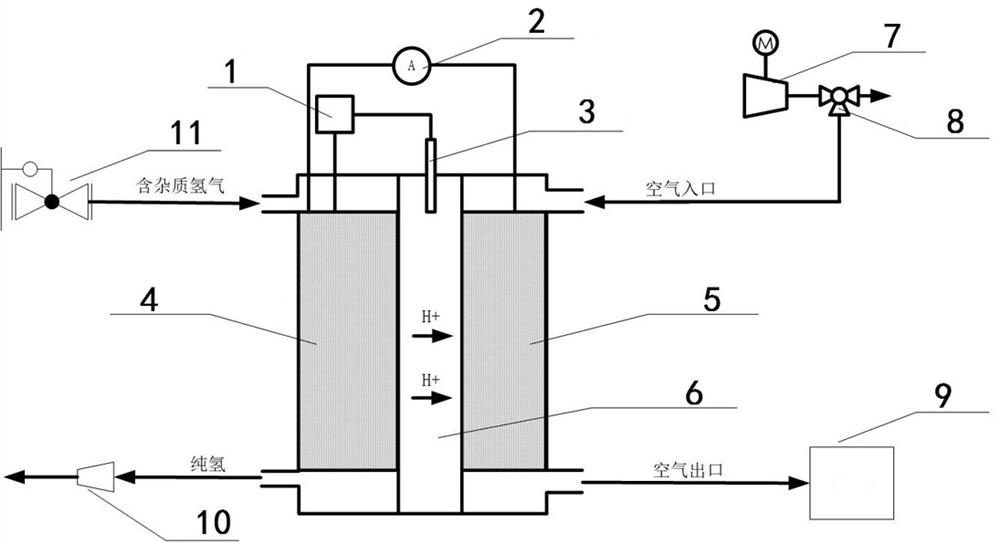

[0051] like figure 1 As shown, the solid state electrochemical reactor further includes an anode electrode layer 4 , an electrolyte layer 6 , a cathode electrode layer 5 and a reference electrode 3 . The anode electrode layer 4 is provided with a hydrogen inlet to be purified and a hydrogen outlet after purification; the cathode electrode layer 5 is provided with an air inlet and an air outlet; the electrolyte layer 6 is arranged between the anode electrode layer 4 and the cathode electrode layer 5; the reference electrode 3 is arranged on Inside the electrolyte layer 6; the anode electrode layer 4 and the cathode electrode layer 5 can be connected by external wires.

[0052] The output terminal of the controller is respectively connected with the anode electrode layer 4, the cathode electrode layer ...

Embodiment 2

[0064] Improvement is made on the basis of Example 1. For CO impurities, the potential of the anode electrode layer 4 is 0.8~0.9V, the operating temperature of the solid-state electrochemical reactor is 50~80°C, the inlet of the hydrogen to be purified and the air The inlet gas temperature is 0~40℃, the gas pressure is 100~250 kPa, and the gas humidity is 20~100% RH.

[0065] Preferably, both the anode electrode layer 4 and the cathode electrode layer 5 adopt a porous carbon structure with catalysts distributed on the surface. Specifically, porous carbon with surface-distributed catalysts is used as the base material, proton-conducting ionomer is used as the binder, and carbon fibers are used as the skeleton to construct a porous electrode capable of transporting gas and protons.

[0066] Preferably, the catalyst of the anode electrode layer 4 is a composite of metal oxide and platinum, which can improve the selectivity of the catalyst to CO, such as titanium oxide (TiO). The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com